Milling Splines Increases Quality, Enhances Versatility

Instead of using a hobbing machine to generate splines in PTO shafts, Weasler Engineering milled them with modified Ingersoll cutters to improve both the flexibility of its machining operation and its part quality.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Although Weasler Engineering has found success hobbing spline shafts in high volumes, the West Bend, Wisconsin, company recently had the opportunity to step back and evaluate if hobbing was still the best way to accomplish this task. After switching to a modified milling platform from Ingersoll Cutting Tool Co., the company improved product quality and enhanced manufacturing flexibility while maintaining the price for its customers.

Weasler produces a family of power take-off (PTO) shafts in high volumes, each requiring six to 21 axial splines. The company originally generated the splines on an older hobbing machine but decided to outsource the job when its safety engineers noted some potential concerns in mid-2015.

“The upside of outsourcing was the time it gave us to choose between acquiring a newer, safer hobber or converting to a different process,” Manufacturing Engineer Scott Stuart says. “The downside was that higher part costs made it difficult to maintain margins and still hold the price line with customers.”

After considering his options, Mr. Stuart leaned toward milling versus bringing in a special-purpose hobber because the milling machine provided more manufacturing flexibility. He tried milling the splines, running trials on an existing CNC machine with a circular mill. “If we could make milling work, we could expand our manufacturing flexibility,” he says. “A general-purpose CNC machine offers more choices than a single-purpose hobber.”

The milling process provided an efficient material removal rate (MRR), and it improved part quality compared with hobbing, as well. However, the tool chosen for the milling trial did not fit well in the active machining area, which could complicate part loading and tool changing when scaled up for production levels.

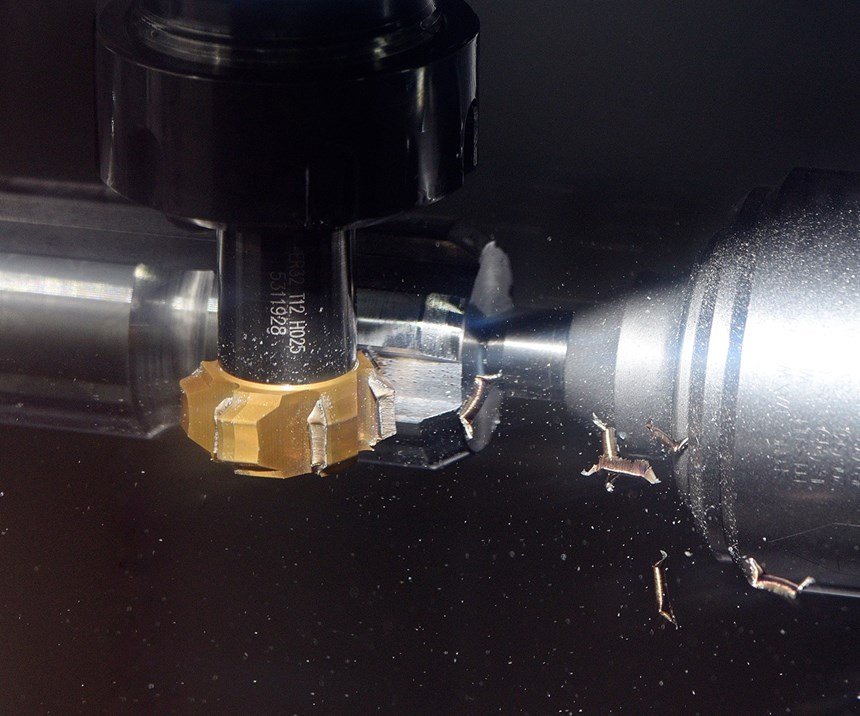

Mr. Stuart reached out to Ingersoll’s Tim Majerus for a modular tooling solution that would maintain both the MRR and quality standards of the original test tool, but provide more operational flexibility. Together, they developed a modified tool based on the Ingersoll Chip-Surfer T-slot tool, which they mounted in a standard star-shaped cutter. According to Mr. Majerus, the Chip-Surfer has proven itself in slotting, grooving and splining operations, so it was just a matter of adapting the tool for Weasler’s specific spline geometries.

The first iteration improved results compared with the original test tool, so Mr. Stuart proposed a DMG MORI NTX 2000 CNC machine with the Chip-Surfer tooling package dedicated to splining. Meanwhile, the pair tweaked the tool and machining parameters to improve efficiency. “With a replaceable-tip tool, we can push the MRR without risk of wrecking an expensive hobbing tool or paying the high cost for a regrind and recoat,” Mr. Stuart says. “Here, replacing a tip takes just seconds.”

The standard Chip-Surfer line includes a variety of tips, including conventional, ballnose and high-feed end mills. Other offerings include chamfers, corner rounds, plunge mills, center drills, engravers and other T-slotters. The tool’s top-face geometry is designed to promote free cutting at lower cutting forces to increase machining rates and edge life. Tip-change repeatability to datum, done in-spindle, is 0.0005 inch for both standard and coaxial operations. According to Ingersoll, change-out takes roughly 15 seconds. Shop owners can choose between alloy-steel, heavy-metal or carbide shanks to match the application’s rigidity requirements. The more ductile alloy shanks are designed to effectively handle high sideloads and interrupted cuts.

Ultimately, the shop chose a star-shaped Chip-Surfer with modified tips, mounted on a standard modular shank. The only modification needed was a tool form exactly matching Weasler’s splines. It operates at 600 sfm and 30 ipm, with depths of cut as deep as 0.32 inch. Tips are changed while the tool remains in the spindle, thereby eliminating touching off and other delays.

Ingersoll modified the form from standard blanks in stock and applied the coating in house at its Rockford, Illinois, headquarters. This eliminated possible delays and supply-chain issues often associated with special tools. “Usually, replacement tips are shipped in a matter of days,” Mr. Majerus says.

The new process, which went operational in mid-2016, now handles Weasler’s entire family of PTO shafts. That includes 50 models, ranging in length from 1 to 9 inches with diameters between 0.75 and 2 inches and slot depths from 0.160 to 0.320 inch. The material is 1045 steel with a Brinell hardness of 180 to 220.

Since implementing the Ingersoll system, part quality has improved thanks to the more concentric splines and a single-chuck operation. Additionally, tool life averages 2,250 splines despite the high MRR. It also improved efficiency at the shop, as the milling system is more flexible than a specialized hobber.

Related Content

Emuge-Franken End Mill Wins ANCA's Tool of the Year Award

Emuge-Franken received the award for its specialized tool based on the new Cera-Cut end mill design.

Read MoreTungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreTungaloy Expands Line of Barrel-Shaped End Mills

The new SolidMeister barrel end mills are efficient tools for complex 3D-surfacing operations used in mold making, orthopedic implants and the machining of other freeform surfaces.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More