Manufacturing Speed for Drag Boats

Advanced Design Technologies LLC's subcontracted work led to quality issues among other problems. Vero Software's Surfcam 2017 R1 increased overall efficiency and quality.

Share

James Faulkerson’s passion, Top Fuel Hydroplane (“Hydro” for short) drag boat racing, provided him with a purpose to invent something new. In 1996, he built a drag boat with a modified outrigger design that provided increased stability and went hand in hand with his new twin-propeller drive system. While the boat had its problems, Mr. Faulkerson knew he was on to something.

In August 2016, his company, Advanced Design Technologies LLC (james.advanced.design@gmail.com) of Las Vegas, Nevada, assisted Tommy Thompson Racing’s Nitrochondriac team in setting a new elapsed-time record for Top Fuel drag boat racing. As a consultant and parts supplier for the team, Mr. Faulkerson provided a set of experimental W-Drive gears, which he engineered and manufactured with the help of Surfcam by Vero Software (Thousand Oaks, California), along with other custom parts.

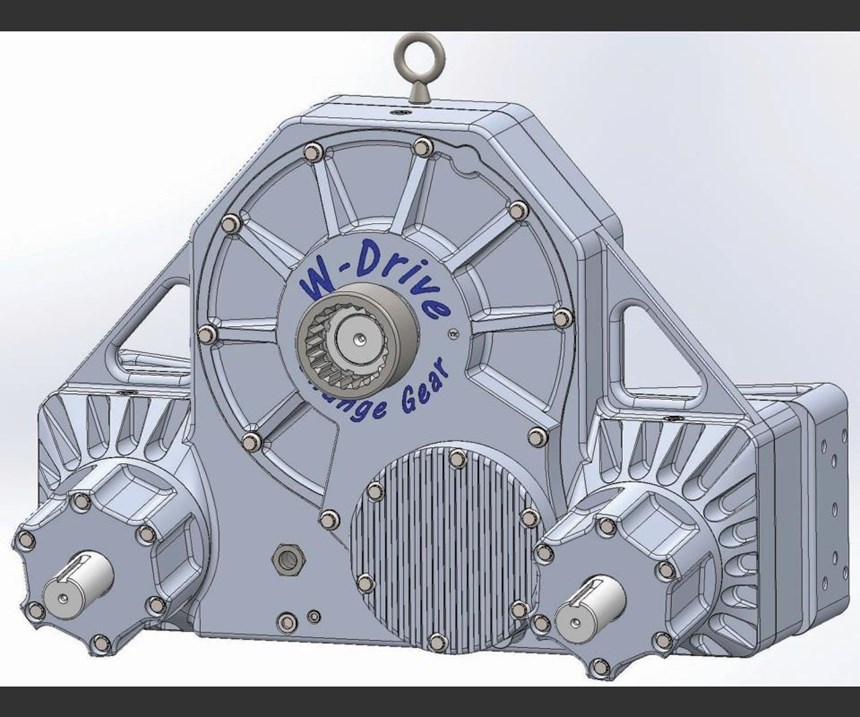

The W-Drive is a power-splitting marine transmission that includes a single-engine input shaft with two counter-rotating propeller output shafts. It includes six gears for input and output overdrive and power distribution for the two propeller output shafts. “For each revolution of the input shaft, there is a set of change gears that can be selected to obtain the desired number of revolutions of the output shafts,” Mr. Faulkerson explains. “A key feature is the counter-rotating propeller output shafts that act to cancel out the propeller torque, creating a balanced propulsion drive system. The W-Drive is a completely new approach to drag-boat propulsion.”

Initially, Mr. Faulkerson manufactured all drive components, except for the gears, using manual mills, lathes and other manufacturing equipment. He subcontracted the gear manufacturing until the late 1990s, when a faulty gear disintegrated and blew a large hole in the bottom of a boat traveling at close to 200 mph, he says. “I decided that I was no longer going to use subcontractors, because I always seem to experience problems. At that point, I decided to make everything myself.”

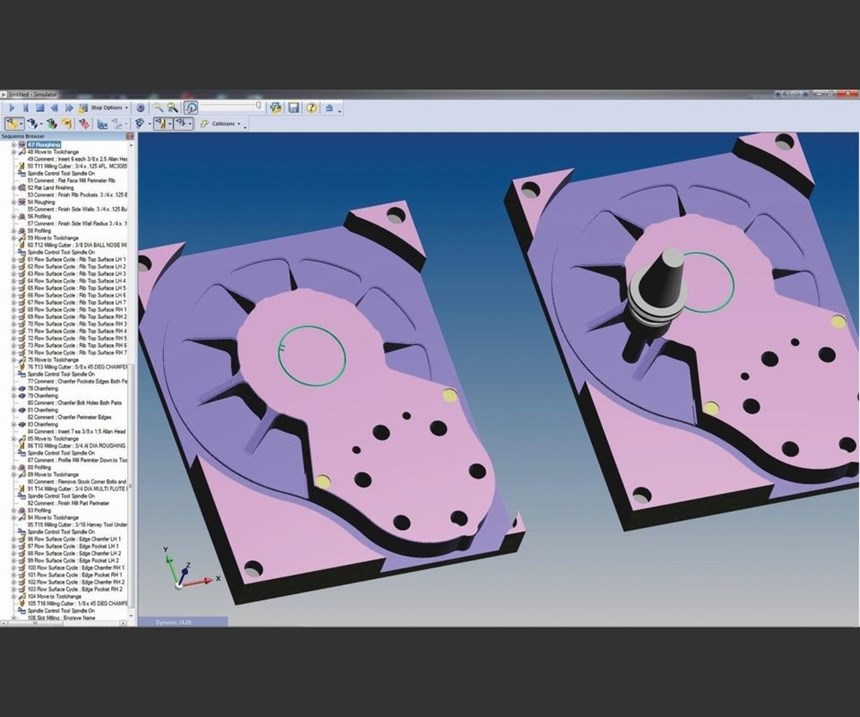

He began his new venture by acquiring a Haas VF-3 mill and SL-20 lathe. In 2002, he purchased the Surfcam Traditional CAM system to program his CNC machinery, later transitioning to Surfcam 2015 and redesigning most of his drive components and parts. He now runs Surfcam 2017 R1, which offers 14 milling cycles with specific applications that range from hole- to pencil-milling, as well as four toolpath-projecting milling cycles. The milling cycles used most often at ADT are the face-mill, hole, roughing, profiling, flat-land-finishing and chamfering cycles. There also are a few unique milling cycles, such as the flow-surface and parallel-lace cycles, that simplify the complex milling of non-uniform 3D shapes and surfaces.

As he manages a job from design to production, Mr. Faulkerson uses the Solidworks CAD system by Dassault Systèmes to create custom parts. He then imports the design into Surfcam, which reads the native Solidworks part file without the need for translation. This seamless interoperability between CAM and CAD systems ensures that design data will completely retain its integrity after importation, Mr. Faulkerson says. He also appreciates the flexibility of the Surfcam tool path, which is designed to ensure that parts are ideally programmed and collision-free via the Surfcam simulator.

A highlight of the CAM system is its roughing-milling cycle, which enables pro-grammers to select and define entry points for each region to be machined. Programmers can also start the roughing cycle from pre-drilled holes and set a preference for ramp or helical approaches. The cycle has been optimized for high-speed machining, including tangential links between passes and optimized retract moves.

Other cycle features include associative depth parameters, which ensure that programming is uniform; intermediate slices, which reduce the size of the steps left by the roughing cycle; and flat-land detection, which machines to the specified Z offset from the top of islands and the base of pockets. In addition, the roughing-milling cycle offers a “check-fixtures” option for collision checking against fixtures, a corner-type option to clean up the last pass’ stepover at each machined Z level to control the behavior of the cycle on sharp corners, and more.

“The Surfcam tool path has the ability to conform to unusual 3D shapes, and Surfcam can cut those shapes efficiently,” Mr. Faulkerson says. “A few of the tool paths are astonishing in machining the rear case on the W-Drive.”

He credits three cycles—comprehensive roughing, parallel-lace and flow-surface cycles—with helping him increase overall efficiency and toolpath quality.

“Simply stated, comprehensive roughing is an application of the Surfcam roughing-milling cycle that, in one cycle, can rough blank material stock to within a specified tolerance of the finished part,” Mr. Faulkerson says. “Defining the tool path again is a simple matter of specifying speeds and feeds; providing an overall tolerance; specifying intermediate slices information (overall lowest depth); and a few other details, and that is it. I was simply amazed at the ease of initially roughing a complex part with a single Surfcam roughing cycle. All I had to do was select an appropriate milling cutter; set feeds, speeds and depth of cut; and select the 3D model; and it rough-machined the entire part.”

The Surfcam parallel-lace milling cycle performs milling operations on several surfaces at the same time. Parallel lace includes built-in gouge protection, which makes it well-suited for machining multiple surfaces. Programmers can use this cycle for roughing, semi-roughing and finishing surfaces. The cycle also includes a “check-surfaces” option, which enables users to specify surfaces that they do not want machined (gouge protection), and allows for the restriction of a generated tool path. Also, users have the option to exclude flat areas to optimize tool-path generation.

“Parallel lace is very powerful in its ability to machine complex 3D-model faces with adjoining edges of planer or radial chamfers,” Mr. Faulkerson says. “The tool path will ‘crawl’ along the 3D-model face in a tangential lacing pattern in addition to simultaneously cutting adjoining edges that contain radial or planer chamfers all in one programmed cycle action. This cycle is used in the cutting of an angular 3D-lofted-model face of the rear case of the W-Drive transmission.”

With one programmed parallel-lace milling cycle, the pocket’s top wall faces and associated edge radii are cut, saving considerable time and simplifying the programming of this milling operation. Mr. Faulkerson says he used Surfcam’s flow surface milling cycle extensively to manufacture the W-Drive alloy encasement parts. The cycle follows the flow of a surface, which is ideal for machining fillets and 3D surfaces. It offers improved surface finish, helical support to reduce link moves, and multiple face and surface support. The tool path is controlled by two types of surfaces that can be selected: “drive” surfaces that produce the basic tool path, and “check” surfaces that are not to be machined or are gouge-protected.

“The beauty of the flow surface is that you can have any shape of a surface between two line curves or surfaces that are bounded by other adjoining surfaces and it will simply machine them,” Mr. Faulkerson says. “You have the ability to control the tool path like never before.”

Related Content

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More