Manufacturing as a Soul-Satisfying Experience

Many shops acknowledge a spiritual dimension to the business of making things. This awareness of a “higher calling” gives a boost to creativity, productivity, quality, ethics and teamwork.

Share

“Spirituality is the common ground shared by many religions,” says Aneesa Muthana, president and co-owner of Pioneer Service, a contract manufacturer in Addison, Illinois.

Ms. Muthana offered this comment while she and I were exchanging messages about the importance of spirituality in manufacturing. I initiated this dialogue after reading this column she wrote for Modern Machine Shop. Her topic was teaching her grandchildren about the value and importance of being involved in manufacturing, especially in the context of a family-owned and -managed business. I found this column not only strong-minded, but also deeply touching at times. The entire piece had a distinct spirituality about it that appealed strongly to me. At the time, I was preparing a presentation on the spirituality of manufacturing to be given at Idea Week, a conference on innovation and technology sponsored by the University of Notre Dame during the first week of April 2019. From Ms. Muthana’s column, it seemed clear to me that Pioneer Service was a fine example of spirituality as a positive value and a benefit to a manufacturing company.

Ms. Muthana wrote that, as a parent and a company leader, she was eager to provide an opportunity for her grandson and granddaughter to discover for themselves the attraction (and the satisfaction) of a possible career in manufacturing. She wished neither to impose on nor to guarantee them future jobs at Pioneer Service, a prosperous and capable job shop that provides precision machine to components for customers in a variety of industries.

In particular, Ms. Muthana cited one crucial lesson that she hoped her grandchildren would absorb: that of "amanah," an Arabic word that means respect, trust, accountability and responsibility. Ms. Muthana and her two brothers had learned the meaning of amanah from their parents, who had founded their shop (a different shop, non-competitive to Pioneer Service) and built it with a combination of talent, perseverance, hard work and sacrifice. If her grandchildren learned for themselves that amanah showed them how to conduct their lives and, perhaps as future business leaders, how to serve both customers and employees successfully, they would be worthy successors to the legacy Ms. Muthana and her family had created.

Spirituality promotes greater creativity, higher productivity, better quality, stronger ethics and more teamwork.

In one of our first exchanges, Ms. Muthana directed me to this statement she had posted on a page in her social media site: “Manufacturers are makers. The process of bringing people together to make something that will go on to serve a bigger purpose is where my passion lies. Knowing that the parts that leave my shop are contributing to the world at large, touching lives and benefiting people fuels my passion.”

This statement is a perfect summation of the many themes I was developing, all of which were based on what I had learned, observed or experienced by visiting manufacturing companies over the years. Although these visits were primarily devoted to documenting how real-world companies were applying metalworking technology, I was often struck by the apparent spirituality of the company owners, managers and employees. This was particularly true in the family-owned job shops that were usually the most rewarding ones for me to visit.

Today, there is a persistent concern that not enough young, energetic and talented people are attracted to manufacturing. This problem overshadows most of the technical challenges facing manufacturing such as environmental sustainability, digitalization and automation. If we want a new generation (of all ages) to come to manufacturing, we need to show that it is not just about shipping product. It is also about becoming creators, artists, seekers, shapers of a better world and builders of new society that values collaborative effort, respects our individual creative potential and protects the natural environment.

All the latest trends in manufacturing technology are compatible with this “higher calling.” In fact, without a sense of this calling, the current renaissance in manufacturing will not live up to its full transformational power. Yet even in the here and now, spirituality benefits key aspects of manufacturing.

Spirituality promotes greater creativity, higher productivity, better quality, stronger ethics and more teamwork. To affirm and enhance Aneesa Muthana’s earlier definition of spirituality as the common space shared by many religions, I would add that spirituality is an awareness of and responsiveness to God or some sacred dimension. Spirituality involves both thought and action. In fact, spirituality can be characterized as a two-way street. It helps make our work better and it helps make us better workers. Spirituality can help us appreciate manufacturing more; likewise, manufacturing can help us grow spiritually.

Creativity

One source of sustaining satisfaction for individuals involved in manufacturing is the understanding that it is a good and worthy business. It is the business of making things — good and beautiful things, things that are useful and desirable. At its essence, manufacturing transforms raw materials to add value and create wealth, which is realized when exchanges in a free market satisfy the customer and reward the producer.

The raw materials on which manufacturing relies come from the natural world, and whether this world is seen as the work of God, the divine creator, or revered as a transcendent source of life and sustenance, this perspective inspires creativity. Dave Painter, founder and general manager of Painter Tool, Inc., in southwestern Pennsylvania, has expressed this common sentiment on his shop's website: “All glory is given to God, being the great designer and original manufacturer. We simply do as our Creator has done. Here at Painter Tool Inc., we seek to honor the Creator by being creative and doing manufacturing.”

Mr. Painter told me that making the connection between human creation and divine creation was important because it affirmed the dignity of work, especially the work of manufacturing. “Work defines who we are and what God wants us to be — creators and sustainers of the good in this world. That’s the true nobility and honor of work.”

The creative elements of manufacturing seem to follow a pattern that is apparent in all creative activity. It is a simple pattern. Typically, manufacturing starts with a product design and then applies the appropriate technology or know-how to put this design into production. Finished goods then bring the benefit of the design to the end user.

This pattern is strikingly similar to the methods of the creative artist. Simply put, the artist’s mind conceives an idea of the truth and beauty he or she experiences in life. The artist’s mind then must give this idea expression. In other words, creative energy has to put the idea into an art form, whether it is a poem, a painting or symphony. This form makes the idea knowable to others. A work of art then has the power to make the artist’s notion of truth and beauty perceivable when it is displayed or performed.

In fact, the creativity of the artist and the manufacturer has been linked to the theology regarding God as the divine creator.

Typically, manufacturing starts with a product design and then applies the appropriate technology or know-how to put this design it into production. Finished goods then bring the benefit of the design to the end user. This same pattern is apparent in all creative activity, especially that of the creative artist. Photo: Pixabay

Productivity

Just as we admire great artists for being prolific, we can be awed by the productivity of modern factories and manufacturing plants. Manufacturers are naturally concerned with productivity. In most cases, productivity is linked to profitability, upon which companies rely to meet payroll and reward investors. Productivity is typically characterized as a “numbers game,” that is, manufacturers look for more output from less input. Is there a spiritual angle to productivity?

Here is one perspective. An increase in manufacturing productivity means there are more goods for more people. The incredible rise in the standard of living for populations around the world is strong evidence of this. Greater productivity enables us to share the bounty of the earth and the fruits of honest labor more widely. Moreover, the drive to improve productivity motivates manufacturers to be more efficient using labor, materials and energy. Using all of these resources wisely and well is the key to productivity.

True Cut Tool has a mission: to praise God by serving customers well. Whenever it can, this shop uses automation such as this palletized system for loading CNC tool grinders robotically. Designed and produced in house, this system reflects a knack for creativity and a concern for productivity.

We can see a glimpse of this spiritual angle on productivity with a look at a small shop called True Cut Tool in New Carlisle, Ohio, just northeast of Dayton. Three generations of the Nicodemus family are involved in this business. They make large batches of specialized cutting tools for milling machines as well as one-of-a-kind custom tools to solve productivity challenges. Larry Nicodemus is founder of the company and patriarch of the family. He and his family belong to the Old German Baptist Brethren Church, a faith community that shares its roots with the Amish and Mennonite traditions. The shop’s core business model is based on humble, honest and honorable service to customers and employees.

Mr. Nicodemus says he and his team seek to praise God by serving customers well. One way True Cut can provide customers with outstanding service and value is to shape and finish precise cutting tools rapidly in large batches. Naturally, the shop uses automation wherever it can, and even invents its own high-production systems such as pallets to robotically load the peg-like tool blanks into an automated grinding machine. The pallets enable this machine to run overnight when the lights are out.

Quality

Of course, a concern for productivity in manufacturing would be pointless if not accompanied by an equal or greater concern for part quality. Manufacturing companies have to be passionate about quality.

Broadly speaking, quality is the pursuit of excellence in every aspect of the manufacturing enterprise. When the work is worthwhile and when it is done well, the effort is satisfying and fulfilling. It is truly creative.

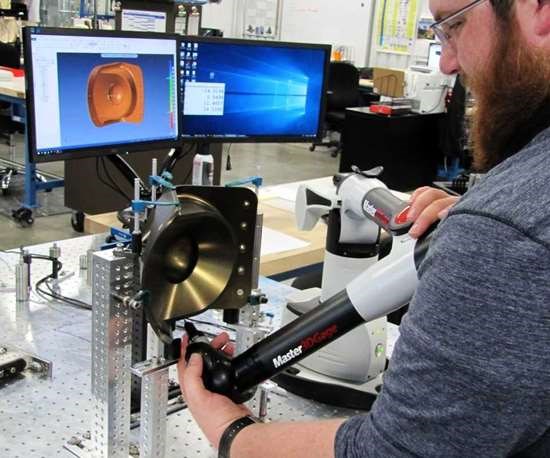

Quality, the pursuit of excellence in every aspect of the manufacturing enterprise, can only be achieved by doing all things lovingly, that is, with vigilance and devotion. Here, we see Jake Blankenship, a quality inspector at Flying S in Palestine, Illinois, where I observed him carrying out quality assurance procedures with intense care and concentration. He clearly loves his work.

Figuratively speaking, the spiritual secret here is putting one’s heart and soul into the work. In other words, to do all things lovingly. Lovingly is precisely the right word in both the meaning and the feeling it carries. If you work in manufacturing, you probably know someone out in the shop or on the plant floor who “loves his work” or “is really good at what she does.” Most likely, they do good work because they love it.

But practically speaking, quality in manufacturing is all about product quality — meeting the specifications. This is a huge challenge. Although science and mathematics must be the basis of every effort to meet this goal, there has to be some passion to applying the intricacies of metrology and inspection techniques. Ultimately, “meeting the specs” requires directing one’s inner being toward the good that flows from achieving certain measurable characteristics of the workpieces. This calls for vigilance and devotion.

The picture above shows Jake Blankenship inspecting an aerospace component at a shop called Flying S, which is located near Vincennes, Indiana. I visited this shop last summer, and I watched Mr. Blankenship use this jointed mechanical arm tipped with a touch-trigger probe to collect data points to measure the part. He was showing me how the part-holding fixture and the metrology software program he was using were developed with 3D printed sample parts before a real part was machined. However, I couldn't help notice the care and concentration with which he carried out the procedures. He was proud of his work and I could tell he was putting his heart into it — and enjoying it very much.

We should note that quality in manufacturing always involves measurement, and measurement always involves comparison to a standard, an accepted absolute. For example, all measurement devices used in manufacturing in this country must be traceable to artifacts or their latest scientific equivalents maintained by the National Institute of Standards and Technology.

Ethics

“Making a personal commitment to doing the right thing all the time is the key to ethical conduct, just as adhering strictly to proper procedures in any production operation is vital. – Gary Neidig, president of ITAMCO

Manufacturing’s insistence on adhering to standards is also the key to a spiritual approach to ethics. In the business world, ethics generally center on trust among a company’s owners, managers, workers, customers and other stakeholders. Companies that demonstrate a high compliance with ethical principles will be rewarded because customers, business partners, investors and job applicants will give them greater preference.

However, ethics have to be energized by some level of spiritual conviction. Otherwise, companies cannot move beyond merely compliant behavior to generous behavior. Spiritual conviction is not difficult to tap into. Ethics ultimately fall back on a moral code, usually one linked to a belief system that gives us standards of behavior, that is, what is right and what is wrong. Of course, the Ten Commandments are a prime example in the Judeo-Christian tradition. Other religions have similar codes and almost all are based on the commandment to love God and thy neighbor.

Gary Neidig, president of ITAMCO (Indiana Technology and Manufacturing Companies), a provider of open gearing and precision machining services to heavy-duty industries, offers this observation: “Making a personal commitment to doing the right thing all the time is the key to ethical conduct, just as adhering strictly to proper procedures in any production operation is vital. I keep in mind that answering to God is ultimately what ethics are all about, and I’d like everyone who is employed here to share that awareness.” He says the company, located in Plymouth, Indiana, seeks to instill this awareness in gentle ways — an open Bible in the lobby is one example. Supporting community activities sponsored by local churches is another way he says ITAMCO makes this connection. Mr. Neidig adds that doing what is right “has to be a broad and generous impulse — doing good wherever and whenever we can.”

The moral codes formulated by most religions are also bolstered by some concept of personal responsibility and culpability that is attached to violations of the code. The traditional word for these transgressions is sin, which is explored briefly in the sidebar below.

Teamwork

Just as upholding a bond of mutual trust is the essence of business ethics, maintaining bonds with coworkers is essential to teamwork on the job. Without teamwork, it is difficult for a manufacturing company to be creative, productive and quality-conscious. One way to build teamwork is to view coworkers with spiritual eyes. We would then see them as fellow children of God, as equal in dignity and worth (even if unequal in ability) and as deserving of the chance to be “the best versions of themselves.” We certainly should see our coworkers as kindred spirits in the pursuit of excellence in manufacturing.

I would like to suggest one more key point about teamwork. The most important spiritual virtue needed to enhance workplace teamwork is humility.

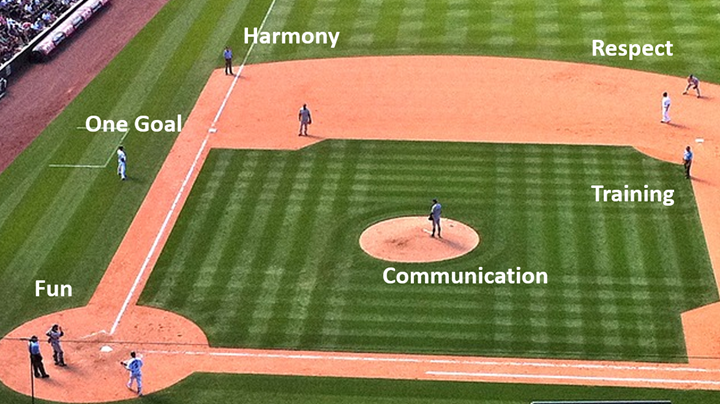

A team has to have a unifying goal or mission. In manufacturing, that is to provide customers with the best product at the best value. This often entails putting the team’s interests ahead of one’s personal interests.

A team has to work together in harmony and cooperation, which requires doing one’s part in coordination with other team members. Treating coworkers patiently and humbly as “internal customers” is one way to do this.

A team has to have leaders and followers who are respectful. Workers have to respect the authority of supervisors and managers. Likewise, supervisors and managers have to recognize the limits of their authority and respect the contributions of those they manage.

A team needs training. Training involves submitting to the lessons of experts, job coaches and mentors. In the best manufacturing companies, no one is exempt from the need for constant training.

A team has to be good at communicating. Information must be shared openly and respectfully. Coworkers have to listen to each other. All this requires humility — especially the listening part.

Finally, a team has to have fun working together. Egotism, arrogance and selfishness get in the way of having fun on the job.

The most important spiritual value needed to enhance workplace teamwork is humility. Humility is necessary to “cover all the bases” that enable a shop to strengthen the bonds of mutual respect and trust that underlie true teamwork. Photo: Pixabay

Lean Is a Means to Virtue

Now let us quickly look at some trends in advanced manufacturing and think about the two-way street of spirituality — how a mindful outlook gives these trends a lift, and how these trends might lift us to greater mindfulness. Lean manufacturing provides an excellent example. Lean manufacturing, also known as the Toyota Production System, originated in Japan many decades ago and was taken up in earnest by U.S. manufacturing companies starting in the 1990s. It is still gaining momentum in this country today.

Implementing lean is often characterized as a journey because lean emphasizes continuous improvement and implies that there is no destination or end point. We can see this journey as a spiritual journey, too. Lean embodies many spiritual values. It fights against waste as an “evil.” It insists that human resources are the most important company asset. It promotes an intense focus on “the other,” that is, on the customer as chief beneficiary.

More significantly, lean brings out the joy in manufacturing. Joy may be the biggest surprise of the lean transformation. Before lean is put into place, working in a cluttered shop area is dispiriting. Looking for missing tools is annoying. Waiting for the next piece or next job to be ready is frustrating. Making mistakes or seeing good work scrapped downstream is disappointing. Lean manufacturing seeks to find and remove the waste that ultimately what drains the life-energy from a workforce.

Kaizen is originally a Buddhist concept.

Kaizen is probably the most important idea in lean manufacturing. Kaizen is a Japanese term that means “change for the better” or “continuous improvement.” In this country, we use it to refer to an intense, structured effort to improve a process by brainstorming, testing and implementing less-wasteful procedures.

In fact, kaizen is originally a Buddhist concept that comes from the words that roughly mean “renew the heart and make it good.” At its best, the concept of kaizen calls for changes in the heart of the business.

Green in Spirit

Likewise, emerging trends such as sustainable or “green” manufacturing get a boost from spiritual consciousness. For example, green manufacturing calls for processes that are economically sound and safe as well as have minimal negative impacts on the environment. These processes should also conserve energy and natural resources. The spirituality of green manufacturing is clear. We are called to be good stewards of the natural world. Stewardship is a spiritual duty to God and humanity. This duty should be energized by a reverence for nature and its resources as precious but fragile gifts.

There is a kicker, though. Sustainable manufacturing is a spiritual responsibility primarily because it sustains human life. That is why spirituality seeks a balance of human and environmental interests, and this should certainly be true in our factories. This is important because this concept of spiritual balance counters the tendency of extreme environmentalism to be anti-manufacturing.

Spiritualize While We Digitalize

Digitalization and Industry 4.0 are current developments in manufacturing that are not beyond the beneficial influence of spirituality. In fact, I see great promise in these developments because they can help us put our hearts and souls into manufacturing on a new level.

Digitalization and digital manufacturing are helping to overcome the dehumanizing effect that mass production and assembly lines have had on workers.

Digitalization simply means that almost all of the information needed in manufacturing can be captured as data to be collected, analyzed and shared on a computer network, including the Internet, of course. Sharing data enables shops and factories to integrate and streamline operations. It is revolutionizing how processes are monitored, controlled and optimized. This radical advance has been called the Fourth Industrial Revolution or Industry 4.0.

The main benefit of digitalization is that we can make better decisions about manufacturing processes because data gives us reliable facts and figures to go on, instead of guesses or assumptions. Using the term “data-driven manufacturing” to describe this approach to industrial production is appropriate. What we are finding, though, is that data-driven manufacturing is at its best when it reinforces people-driven manufacturing.

Digitalization is also the key to digital collaboration — networks of designers, makers and users working together by sharing data files across the Internet. This is why the Maker Movement and the proliferation of MakerSpaces are so important. These are small-scale, grass-roots prototypes of digital manufacturing. MakerSpaces enable creative individuals to be designers, makers and users in a single, unified experience. One step up are the micro factories in which products are being designed collaboratively online by a community of experts with input from potential customers. Parts are machined or 3D printed directly from the digital design files, and then the finished products are assembled in small batches.

Something even more significant may be going on here. Digitalization and digital manufacturing are helping to overcome the dehumanizing effect that mass production and assembly lines have had on workers. This has been a long-standing complaint about factory life. Too often, factory workers had no connection to the integrity or excitement of the designer’s invention and no connection to the usefulness or beauty of the finished product.

We can get away from this by moving to these new modes of manufacturing. For the first time in history, digitalization enables designers, makers and end-users to be on the same page — literally on the same digital platform and even in the same maker space, which could be the micro factory down the street. Designers, makers and users are more likely be unified in the creative, artistic trinity described earlier.

More About Amanah

One other thing that Ms. Muthana shared with me when I originally contacted her was this poster of her shop’s core values, along with an explanation that included many vital ideas about spirituality. She told me that when she originally perceived a need to develop company core values, it was “driven by my Muslim faith and by amanah in particular. The literal English translation of amanah is ‘fulfilling or upholding trusts,’ but in Islam, it also means fulfilling one’s obligations to God and His creations. Honesty. Integrity. Respect. Accountability. Responsibility. It is all of these things and more, and of course many non-Muslim individuals live it, even if they’ve never heard the word amanah.”

Aneesa Muthana, president of Pioneer Service Inc., is a regular contributor to Modern Machine Shop. Photo: Aneesa Muthana

Ms. Muthana explained that she did not want to dictate core values to her team or to have them just be pretty words on the walls. “I met with my team to brainstorm, discuss, and develop core values that define our success. I speak of these values often because I’m proud of what my team and I came up with together. Each of us has roots in amanah, but also in Christianity and in secular business beliefs. They are the product of an inclusive approach, and I expect myself and my team to live by them every day. They remind us that there are far more important considerations than the bottom line. Success without integrity, learning, and kindness is not success!”

Yet we do want to be successful in manufacturing. To a great extent, the long-term economic well-being of our country relies on the potential to generate wealth that is inherent in manufacturing. When manufacturing prospers, we have a better chance to prosper economically as individuals, as families and as a society. The intent of this article is to show that the spirituality in manufacturing can benefit the individual and that one’s personal spirituality can help a manufacturing company prosper.

However, we should remember that we cannot have heaven on earth. No amount of spirituality, however earnest and sincere, can make our shops and factories perfect places to work. Our manufacturing companies will always fall short of some moral or spiritual ideal. Likewise, businesses can fail, creativity can dry up, productivity can sag, ethics can quaver and teamwork can unravel.

However, that is part of the adventure. As the English novelist and theologian G. K. Chesterton explained, whatever is our walk of life, it should be taken as a spiritual adventure, because God is an adventurous God. God has taken the chance that, by creating us through perfect love and complete freedom, we will in fact, accept our freedom and return that love.

Being in manufacturing calls us to be makers and creators, but we should answer that call in the spirit of an adventure.

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More