Managing the Micro-Milling Process with Tiny Cutters

The engineering of this line of small end mills brings out both the challenges and opportunities in milling hard-to-machine materials on a micro scale.

Share

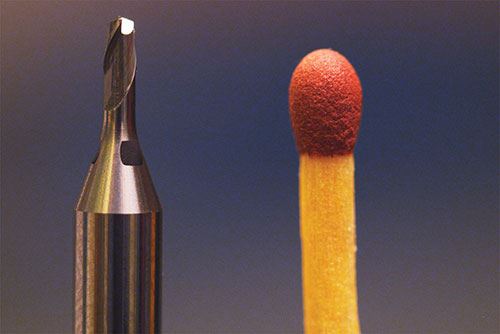

Effectively controlling heat is the governing principle behind a new line of solid carbide milling cutters developed in Switzerland by Mikron Tool (U.S. office in Monroe, Conn.). Called CrazyMill Cool, the milling cutters range in diameter from 0.3 to 6.0 mm (0.12 to 0.236 inch). The cutters are designed to control the factors that produce excessive heat at the tool/workpiece interface. This is accomplished through a combination of design elements. These include a special grade of carbide, a new coating, original geometry of cutting edges, and most notably, internal channels that deliver coolant through ports in the shank where the milling flutes begin.

According to developers, these cutters are capable of significantly higher cutting speeds and depths of cut in tough-to-machine materials compared to conventional end mill designs in this size range. These results are obtainable in stainless steel, titanium, chrome-cobalt alloys and other so-called super alloys. The new tools are said to be especially effective for cutting slots, and milling pockets and contours. The same cutter can be used for both roughing and finishing operations because the lasting sharpness of cutting edges provides efficient chip formation in roughing as well as the creation of smooth surfaces in finishing.

A Firm Foundation

Mikron Tool’s engineers in Switzerland recognized that controlling the negative effects of heat in the cutting zone begins with the grade of carbide of which the new cutters are made. It requires an advantageous combination of hardness as well as toughness. These characteristics were achieved by formulating a mix of extremely fine grains of cobalt and tungsten. Blanks from this mixture are formed through an extrusion process.

The hardness of the solid carbide enables it to cut well-formed chips in difficult-to-machine materials while resisting chipping of cutting edges. The toughness of the material helps the shaft resist breakage from cutting forces and keeps the tool from vibrating. Although a balance of hardness and toughness is sought by all cutting tool manufacturers, Mikron contends that its manufacturing processes result in properties that surpass current fine-grained carbide structures. Moreover, this carbide material facilitates the formation of the internal cooling channels.

Cutting Geometry

For the intended results in stainless steel and other difficult-to-machine materials, the developers focused on a geometry that maintains a robust cutting body, that is, the spacing and spiraling of the flutes are relatively wide open. Radial relief and a very specific cutting edge preparation are tailored for stainless steel, but are equally applicable to high-nickel alloys and titanium, the developers say. The preparation of the cutting edge prevents it from being overly sharp and vulnerable to the formation of microchips and cracks.

The cutters receive an application of the company’s newly developed Exedur coating, which exhibits a very low friction coefficient and low affinity to steel. This helps it control a built-up edge when milling stainless steel and other ferrous materials because these materials do not adhere well to the coating. Furthermore, the coating is said to have high resistance to oxidation and high heat hardness. High heat hardness is important because heat tends to be concentrated along cutting edges and would otherwise burn away the coating and leave the edges unprotected.

What Makes this Cool Tool Cool

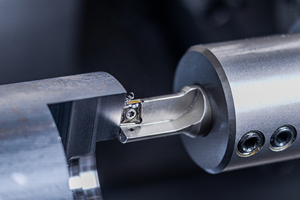

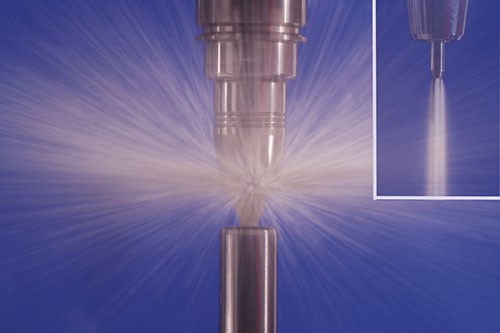

The most unusual feature of the CrazyMill Cool line is the presence of internal cooling channels that go through the shank. Depending on the size of the tool, there are three or four channels located symmetrically between the center of the cutter body and its periphery. These channels form openings where the shank is cut away to create the shaft taper above the fluted portion of the tool.

These openings enable coolant to flow along the exposed diameter of the tool to the entire length of the cutting edges. In comparison to the diameter of the tool, the coolant channels are large, thus discharging a copious amount of coolant regardless of the position or orientation of the tool. The number of channels and the volume of coolant they deliver are highly efficient in carrying away heat generated by the friction of the cutting action. This prevents cutting edges from absorbing sufficient heat to degrade the binder in the carbide and cause cracking and wear. According to developers, this integrated cooling system is chiefly responsible for the long life of these milling cutters and their ability to perform at substantially higher speeds and feeds than conventional tools in this size range. Mikron Tool claims that no other manufacturer makes cutters in this size range with internal cooling capability.

The highly localized and steady stream of coolant also flushes away chips and prevents them from being recut. This protects the integrity of the cutting edges as well as the surface of the workpiece for a finish that developers say is comparable to one produced by grinding.

Another benefit of the relatively large coolant channels is that machines with conventional through-tool coolant systems do not require special filters, chillers or pressure intensifiers to be effective. Low-viscosity oil is recommended for best results, although emulsions can also be used. Recommended flow rates and pressure increase in proportion to the diameter of the cutter, as shown by the data given in the product catalog.

Productivity

The performance characteristics of the CrazyMill Cool series enable it to mill a channel in solid material at an infeed depth of 1 to 1.3 times the cutter diameter, developers say. This contrasts to the 0.1 to 0.2 times diameter infeed typically recommended for conventional milling cutters. Likewise, permissible cutting speeds for the new tool are substantially higher than those recommended for conventional cutters. In stainless steel, for example, the new tool runs 4 to 8 times faster. In titanium, it runs 5 to 10 times faster.

Based on these figures, Mikron Tool expects applications to improve productivity by a factor of 10 to 20. This gain more than offsets the higher cost of the new tool, which is roughly 2 to 2.5 times the cost of comparable conventional tools.

The CrazyMill Cool is available in three versions: a short version for maximum depths 1.5 times the tool diameter, a medium version for depths 3 times the diameter, and a long version for depths 5 times the diameter.

Related Content

Ceratizit's Updated Tooling Solutions Improve Machining Performance

The company has upgraded its EcoCut indexable inserts lineup, as well as introduced two new toolholding and workholding solutions.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreThe Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read MoreCeratizit Product Update Enhances Cutting Tool Solutions

The company has updated its MaxiMill 273-08 face mill, WPC – Change Drill, as well as the HyPower Rough and HyPower Access 4.5-degree hydraulic chucks.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.png;maxWidth=300;quality=90)