Making The First Cut

Almost every shop has a metalcutting saw. However, many of these shops may be missing a throughput reduction opportunity by under-utilizing this cut-off step in the manufacturing process. Here's how one shop integrates precision sawing in its part production flow.

Share

Metalworking shops manufacture parts in series of operations. The more complex the part is, usually the more operations need to be performed to finish it.

If asked, many metalworking shops would say their part production process begins when a blank is mounted on the table of a machining center or the chuck of a turning center. However, in many cases these slugs are created from bar stock or billets. Therefore, the initializing metalworking operation is actually the cut-off saw.

As delivery and quality pressures mount on shops of all sizes and descriptions, many ways to streamline the throughput of parts are being evaluated. A few shops have turned attention to the sawing operation as a source of savings.

One such shop is New Dimensions Precision Manifold, Incorporated (Union, Illinois). This shop has successfully incorporated cold sawing into the part production process flow. As a result, significant cost reductions have been seen along with a reduction in lead-time.

We talked to shop owner Marty Halwix about how New Dimensions benefits from including the cut-off station as an integral operation in the shop's work flow.

Finding A Niche

New Dimensions started out about 13 years ago in typical job shop fashion. For the first five years, it would make anything for anybody.

"Then along came a recession," recalls Mr. Halwix. "That bump made us take a look at our business and decide to specialize in order to differentiate our shop from other job shops." The specialty New Dimensions chose was the manufacturing of hydraulic manifolds.

It was a good decision. After a few short years, the turning department was phased out, and now the shop only uses CNC machining centers to manufacture the hydraulic blocks.

Moreover, four expansion moves later, the shop shipped 300,000 manifold blocks last year. From 1995 to present the shop has added 90 employees. Business is good and getting better. New Dimensions has again outgrown its location and has just moved into a new plant along with its current staff of 130 employees.

Taking Care Of Business

"We have about 14 active customers," says Mr. Halwix. "We work with them in a Kan Ban system of production and inventory control. Generally, orders come to us via a phone call. We rarely even see a purchase order. Lead times are one to two weeks, and lot sizes run from 50 to 250 pieces."

With specialization came the necessity to streamline and optimize shop production. To accommodate customers' needs, which include no-excuses production to Kan Ban schedules and the ability to accommodate prototype work, New Dimensions has evolved its production system to be flexible and efficient.

A big part of the production flexibility comes from an innovative work schedule that New Dimensions uses to give it agility while operating under the tight yoke of Kan Ban. "We run the shop 3 1/2 days a week," says Mr. Halwix. "The shop works three 12-hour days and a fourth 6-hour day. All of our mandatory production scheduling obligations and shop capacity are built to fit the shorter workweek."

"We then use the remaining time in a week to produce prototype jobs, emergency orders, maintenance, and other less frequently recurring projects," he continues. "We man the shop with a skeleton crew, as needed, to take care of non-production work."

Prototype work is a good example of throughput success. "We've reduced the lead time for prototypes (one to five pieces) from two weeks to three days," says Mr. Halwix. "That was accomplished by significant investments in tooling and operator training."

A large tool storage area contains sufficient inventory to accomplish most operations required to make hydraulic blocks. "Getting work through the shop in three days automatically means we must have the cutting tools on hand," says Mr. Halwix.

The shop is a Matsuura (Sudbury, Massachusetts) house having standardized its machining centers on a single maker. It simplifies tooling and fixturing, allowing the shop to be flexible in allocating work to any open machine. Training of the operators is simplified as well because the controls are identical.

Another way that New Dimensions speeds throughput is by training operators to both run the machine tools and set up new jobs. Classes are held in the shop two days a week to help cross train operators on different machining centers, verticals and horizontals, as well as to familiarize them with setup requirements.

It Starts At The Saw

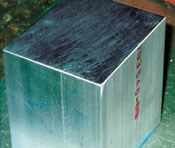

At New Dimensions, the hydraulic blocks begin their journey through the shop being cut off 12-foot billets up to 6 inches square. The shop has five Kaltenbach (Columbus, Indiana) saws and has worked with these machines for six years. Four of the saws cut aluminum, and the fifth is dedicated to cutting dura-bar cast iron.

The decision to invest in these saws came after some trial and error. "Through the years we had used different saws to cut the billets for our manifolds," says Mr. Halwix. "The Kaltenbachs allow us to hold 0.005 inch tolerance and a surface finish of 40 to 70 RMS, which is excellent for our needs."

Because of the dimensional and finish accuracy produced by the cold saw, billets come out of the cut-off operation ready to be machined. "We've eliminated the need to skim cut and square-up the blocks on the machining center," says Mr. Halwix. "I figure we save a couple of minutes machining time per block and at least one handling on each because of precision cold sawing."

With an annual shipment of more than 300,000 hydraulic blocks, that's a significant cost saving to the shop. Another advantage the shop has derived from precision sawing is that closer tolerance cutting saves material. Over the annual production run, these small amounts per block add up.

What Is Precision Sawing?

As a metalcutting process, precision sawing is bound by the same constraints as precision machining. Vibration is a prime enemy of both milling and sawing. "It was excessive vibration from our original band saws, and the resultant chatter that was produced, that pushed us to look at cold sawing and, eventually, Kaltenbach," says Mr. Halwix. "Holding dimensional tolerance and any kind of good surface finish requires a structurally stiff saw so chatter inducing vibration doesn't begin."

The saws that New Dimensions uses are up acting, which means the saw blade travels upward through the worktable. The material is cut on the upswing of the blade.

Some advantages of this saw design include clear access for setting the workpiece stops. The blade resides below the table and out of the setup operator's way.

Cutting with this type of saw uses gravity to help clear the cutting zone of accumulated chips for better chip flow. Coolant is applied from the bottom as well. Because the saw moves up through the bottom of the workpiece, chips and coolant do not lay in the cut but rather fall away. This reduces re-cutting of material.

To help New Dimensions get the usable surface finish tolerances, the Kaltenbach saws use an automatic retract cycle that preserves the cut finish. This is especially critical on aluminum.

Most of the surface damage that occurs on aluminum workpieces is caused by the retract stroke of the saw blade. As it moves out of the cut, any contact with the workpiece walls will mar the surface finish.

Kaltenbach and other saw manufacturers use an automatic offset cycle that puts a prescribed distance between the retracting saw blade and the cut blank. When the saw reaches the end of its cutting stroke, a feed gripper that holds the bar or billet pulls the stock back from the cut zone.

Once the stock is pulled back, the saw's drive assembly moves half the distance toward the already offset bar or billet. These movements create an air gap for the blade to retract through without encountering either side of the cut material.

Although this automatic cycle adds about one second to the cut-off operation, the time is well spent from New Dimensions' perspective because it can eliminate clean-up skim cuts when the blanks hit the machining center.

Is It For You?

As metalworking shops search for ways to increase the amount of work they put across their machine tools in a given time period, analysis of the entire workflow process should include the cut-off operation. If done right, as in New Dimensions' case, the savings can be substantial over a year's run of work. Even incremental improvements such as halving the amount of stock remaining on a cut-off blank impact a shop's throughput over time.

In general, tactical use of the sawing is not going to deliver dramatic productivity results for most shops. However, as shops look strategically at effective ways to reduce costs by streamlining processes, sawing should be included in the overall evaluation as one potential source of improvement.

Read Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)