Machining Module Automates 3D-Printed Part Removal

Metal 3D-printed parts require machining to remove them from the build plate. A module that integrates a band saw and milling spindle automates this process.

Share

ECi Software Solutions, Inc.

Featured Content

View More

3D printing methods build parts layer by layer, but most require a platform or build plate to serve as the starting point. The first layer adheres to the plate, and everything that follows builds on this surface.

This fact means that additive manufacturers who work in metal have to find ways of removing workpieces that are essentially welded to the build plate. The challenge is to free the parts without damaging them, but also to protect the build plate so that it can be reused. Common part removal methods include the use of a bandsaw or wire EDM to remove the parts outside of the 3D printer; build plates are then machined separately to remove excess material and return them to a usable state. (While hybrid machines that combine 3D printing and machining are becoming more common, these are typically designed to machine a part that is still affixed to the build plate.)

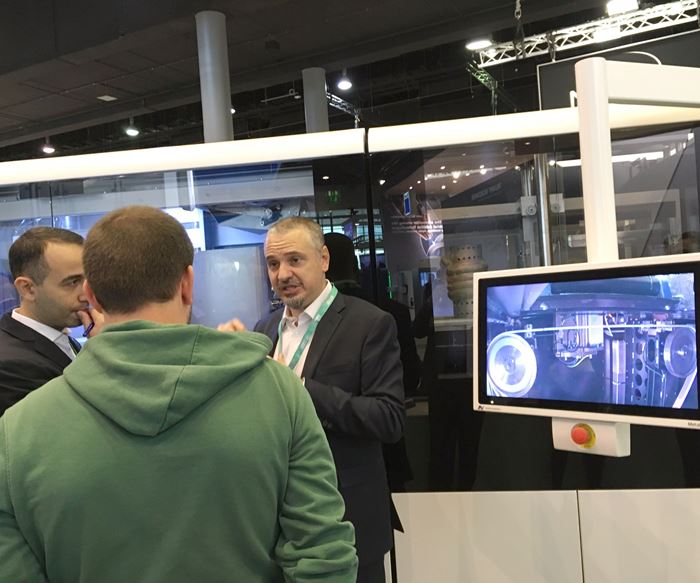

At this year’s Formnext show for additive manufacturing, Editor-in-Chief Peter Zelinski spotted a module from Additive Industries that can be installed on the company’s selective laser melting (SLM) systems to tackle this removal step specifically.

After a 3D printing cycle is complete, the Product Removal Module inverts the build plate so that the parts hang underneath. Then a band saw cuts the parts free (shown on the video feed in the first image above) while they are supported by a custom foam carrier (second image) that prevents damage. The module then flips the build plate over and machines the surface flat again so that the plate can be reused. The process happens automatically, without the need for an operator to move the build plate to external equipment, so that production can continue unattended.

See other AM developments on display at Formnext in this slideshow.

Related Content

-

4 Ways 3D Printing Is Changing Medical Implants

Additive manufacturing provides new ways of making medical implants, but its impact is greater than this. How 3D printing is changing medical manufacturing and improving patient outcomes.

-

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

-

6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=150)