Machine Monitoring in a CNC Swiss Shop

Bold moves put this company well on the road to data-driven manufacturing.

Share

Gary Bruner, the president of Carolina Precision Manufacturing (CPM) in Mooresville, North Carolina, “discovered” the remarkable value of machine monitoring shortly after he had a system installed late in 2015. CPM is a CNC Swiss shop that specializes in small-diameter, close-tolerance turned parts that it produces for a range of customers, the majority of them in aerospace. The installation of the machine monitoring system had gone very smoothly and rapidly only a few weeks earlier. Mr. Bruner had all 36 of the shop’s Marubeni Citizen-Cincom Swiss-type CNC lathes connected to the system from MachineMetrics over a period of about two weeks. CPM, a company of about 60 employees, was still learning about and getting used to the monitoring system. Mr. Bruner and his small staff of production managers and process engineers were also still learning how to best use the data it as collecting, analyzing and reporting. Then one morning…

Mr. Bruner logged onto the monitoring system from his laptop at home before breakfast and started checking machine status. At a glance, he could see that two of the machines assigned to a lights-out operation were not in production. He checked again after finishing his meal. The machines were still down. He knew the morning shift-change and restart procedures should have been completed by that time without such a lengthy delay.

As soon as he arrived at the shop, he went to the cell where the machines were located to investigate. “What’s wrong with machines 51 and 52?” he asked.

“Nothing. Why?” was the response from K. C. Cobb, the operator on duty at those machines. He explained that the normal startup procedures were in progress as usual—clearing chips, checking and changing tools, replenishing the coolant supply, inspecting the lube system and other maintenance checkpoints, restocking the bar feeders, and so on. Mr. Bruner could see that the operator was doing all the right things and in the right order, so what was the holdup?

Further discussion and questioning revealed that these startup procedures were simply not as well-organized or as timely as they could be. Mr. Bruner, Mr. Cobb and the other operators working in that cell developed a plan to streamline these procedures and recapture as much as an hour and a half of production each day. One key benefit would be a bigger reward for the crew in that cell under the company’s bonus system, which is based on daily production records.

“The prospect of regaining 250 to 300 hours of uptime over a year from just two machines in one cell was a real eye-opener,” Mr. Bruner recalls. The payoff for the machine monitoring system was becoming apparent, and it was happening sooner and to a greater extent than expected. “This was one of the first big lessons we learned about machine monitoring: that it is a tool for finding problems that we didn’t know we had. We also saw that it would be a tool for finding and addressing issues as they came up, not after they had happened,” he says.

Looking back, Mr. Bruner makes some other telling observations about the shop’s experience with machine monitoring. These include:

- Shop culture makes a difference. CPM was primed for a smooth adoption of machine monitoring because employees were already well-focused on production targets and teamwork.

- A pilot installation program is optional. CPM connected all of its machines at once, and all employees in production made the transition at the same time.

- It is important to find a vendor who is willing to do some custom development to meet special needs. For example, CPM asked MachineMetrics to add some detailed entries for operator reporting to catch trends that were contributing to any excess part rejections.

- Shop should focus on the data that really matters. The system at CPM can display how much money each machine has not earned because it didn’t hit production targets. Nobody wants to be in a money-losing situation.

Perhaps the most important factor for CPM, Mr. Bruner says, was deciding to implement a machine monitoring system without hesitation or reservations. In September 2015, he looked at an active machine monitoring system on a visit to a supplier’s facility. He liked what he saw, and signed a purchase order with MachineMetrics that December. Half of the shop’s machines were connected by the end of the month; the other half shortly into the new year.

Cells Are the Key

Mr. Bruner started CPM in 1999 after his employer, a large aerospace firm, moved one of its major manufacturing operations to the Charlotte area. Most of the suppliers to this company did not follow. Then relocated in North Carolina with his family, he saw an opportunity to start a CNC Swiss shop to fill part of the gap in the local supply chain. Beginning with two Citizen Swiss-type lathes, the new company grew steadily as it added more customers and added to its capability by investing in Swiss machines for a range of workpiece diameters.

Mr. Bruner attributes this success to two main principles: (1) sticking exclusively to CNC Swiss turning (and some critical secondary operations on drill/tap machines) and (2) being a stickler on providing reliable, on-time delivery of defect-free parts. The company regularly wins supplier-of-the-year awards from its largest customers.

CPM now occupies two buildings in an industrial park on the outskirts of Mooresville, which is about 20 miles north of downtown Charlotte. Each building, across the road from the other, houses roughly the same number of machines—all Citizen Cincom Swiss-type lathes. The oldest of the company’s machines was installed about 12 years ago; the newest one last year.

The most important development in CPM’s recent history was reorganizing the production areas into cells consisting of a maximum of six machines each. “Simply adding more machines in a row was becoming cumbersome and inefficient. The cells give us more clarity and a sense of purpose in our production areas,” Mr. Bruner says. Cells are largely self-contained, each with its own parts washer and auxiliary equipment. Nearby cells share a cutting tool vending machine, barstock storage and an inspection station equipped with a coordinate measuring machine.

In addition to more efficient operation, the cellular approach gives the teams assigned to each cell more responsibility and accountability. The company’s bonus system, established at the same time as the cells, is based on the performance of the team in each cell as determined by how well it meets production targets for that cell. “This naturally aligns employee goals with company goals. We’re all on the same mission,” Mr. Bruner says.

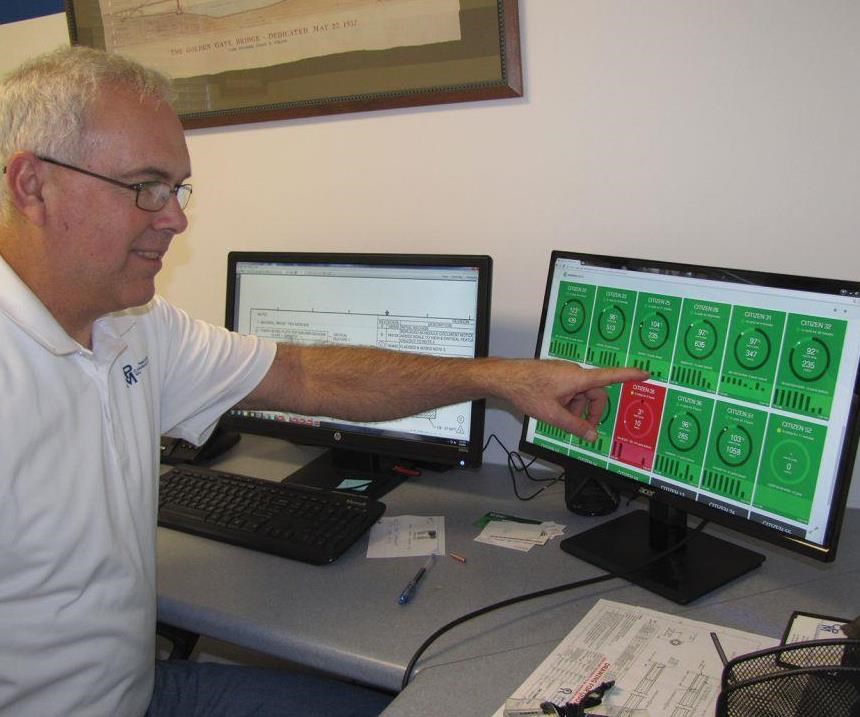

Both the cell-based organization and the team culture it promotes were in CPM’s favor when machine monitoring was implemented. Each cell, for example, now has its own large-screen monitor for the factory dashboard, and each machine has a touchscreen tablet for operator interaction. Details of how smoothly the installation proceeded reveal further insights into the special qualities of this shop and the system supplier it worked with.

Making the Leap

“Machine monitoring was not on our radar when I first saw how one of our suppliers was using a system from MachineMetrics. A light bulb in my head lit up,” Mr. Bruner recalls. He understood the importance of keeping tabs on production stats, job status, uptime and setup. He also understood that current methods were time-consuming, after-the-fact, imprecise and spotty. There was no way to know how well the shop was doing right at a moment.

A machine monitoring system would certainly provide that clarity, he believed. One of the features of the system in place at the supplier he visited was the distinctive look of the dashboard overview of current machine performance. Mr. Bruner liked how this information was displayed. “Each machine was represented by a tile that was green, orange or red. Green meant the machine was running and on pace to meet its production target. Orange meant the machine was falling behind and performing below expectations. Red meant the machine needed immediate attention because it was not running or that production had dropped below a critical level. If you’re a manager or supervisor, you make sure the machines in red are taken care of right away,” he says.

In particular, Mr. Bruner liked the way the system tracked production against goals and translated that performance in terms of dollar value—the monetary impact of falling behind or getting ahead of a job schedule. The Workcenter View (displayed on an internet-enabled touchscreen tablet) was also appealing. This view shows the same ring and traveling dot that represents how close the machine is to “winning the race” (meeting production goals), with other bar graphs and readouts of performance measures alongside it. Additional data and reports are available by clicking on the tile. All displays are configurable to the shop’s preference.

After making the decision to install a machine monitoring system, Mr. Bruner moved forward quickly. He and other top managers reviewed several systems, but favored MachineMetrics’, because it offered the display of data they preferred; had numerous, well-presented reports in analytics; was capable of customization and enhancements; and had low up-front startup costs. “We were determined to jump in and hook up all of our machines right away. Being entirely a CNC Swiss shop with the same brand of machine tools throughout made this a logical choice,” Mr. Bruner explains.

This does not mean the installation faced no challenges. Eric Fogg, COO of MachineMetrics and the company’s chief installer, had agreed to implement the system in two phases—first in the main building and then in the facility across the street. All of CPM’s Cincom lathes had Mitsubishi controls, but the newer and older models had different connection requirements. This became apparent when CPM submitted a spreadsheet listing all models, serial numbers, control types and software versions it was running.

Mr. Fogg created an action plan to connect each machine. As it turned out in this case, the newer machines needed an MTConnect adapter to format machine data into the standard language adopted by almost all monitoring system providers. MTConnect is the open-source, interoperability standard that translates machine tool data into a common, internet-based language. MachineMetrics developed this adapter specifically for Citizen machines with a Mitsubishi control. CPM was the first customer to use this adapter.

This adapter enables the monitoring system to access all of the information shown by the machine’s operator interface. The older machines required a hardware device to interface with the programmable logic controller to extract data such as in-cycle time, part counts and alarm status. Although this data is limited compared to that of the machines equipped with the MTConnect adapter, it was adequate for the most important reporting and analysis functions.

In the meantime, CPM had its maintenance staff install Ethernet cables to the machine tools and wireless hubs at each cell. Six 60-inch flat-screen TVs were purchased from a local discount retail outlet (clerk at the store: “Are you opening a new sports bar?”). These units are mounted where they’re highly visible in each cell. Thirty-six tablets were also acquired, one for each machine. Whereas the machines are hardwired to the monitoring network, the tablets are wireless.

It took Mr. Fogg two days to connect the first 18 machines. This involved about 15 minutes of downtime at each machine. A few weeks later, he returned to connect to the remaining 18. When all of the machines were connected, the team in each cell was trained to interpret the displays and enter appropriate codes to categorize reasons for downtime, part rejects and setup time.

Things to Think About

Mr. Bruner is quite open about his experiences with machine monitoring. He believes that there are a number of topics other shops ought to consider or be aware of when contemplating this step toward data-driven manufacturing:

Cyber security. The monitoring system has a dedicated server on a subnet isolated from other servers on the shop network. This dedicated server is linked to the cloud-based MachineMetrics platform. As Mr. Fogg points out, cloud-based systems are protected by much stronger measures such as high levels of encryption and redundancy—measures that are not easily duplicated or maintained on a closed, on-site system.

Start-up costs and maintenance. CPM paid a one-time installation fee for the initial setup and training, plus the costs of on-site integration. Mr. Bruner estimates that this investment was less than $5,000 (including the monitors, tablets and new cabling). In addition, the shop opted for the mid-level “Lean Shop” package of features in MachineMetrics’ pricing structure, at a cost of $100 per month per machine. There are no charges for additional upgrades and support. (Because the system is cloud-based, enhancements become available to all users simultaneously and automatically.) “I look at it this way: Essentially, machine monitoring is free. We are on track to see at least a 20 percent increase in shop productivity in our first year with monitoring. That more than pays for the system,” Mr. Bruner concludes.

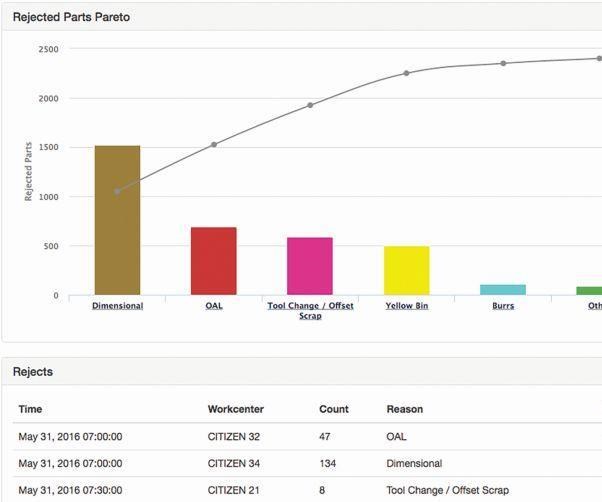

Customization. MachineMetrics worked with CPM to match the shop’s quality system of “red bin” and “yellow bin” part-rejection workflows. Operators reject parts by depositing them in the red bin and entering the reason for rejection into the Workcenter View. If the quality of the part is questionable, they deposit the part in the yellow bin and enter the appropriate yellow-bin category, with notes explaining the issue. Quality managers keep an eye on Pareto charts that show what parts are in the yellow bin and the associated reasons. When parts are placed in the yellow bin, they walk over to the machine, inspect the parts and re-allocate the rejection category. MachineMetrics added a few additional views and forms to the system’s part rejection feature to track this procedure.

CPM also asked for some enhancements to the setup-tracking function. This enables the shop to measure setup time against a standard and issue notifications when setup appears to be excessive. “Setup issues are usually quick fixes, but over time, the accumulated savings are substantial. We concentrate on setup like we never have before as a result of what the data showed us,” Mr. Bruner reports.

ERP integration. CPM has two goals for a basic integration of the machine monitoring system and its enterprise resource planning (ERP) system. One is automatic part-count reporting so the ERP system can update production schedules more quickly and more accurately. The other is less manual data entry for operators. “We figure that the shop overall can save three hours a day by interfacing the systems and reducing manual entries,” Mr. Bruner says. MachineMetrics is currently developing the custom software for this integration. Mr. Fogg notes that interfacing with ERP systems is one area where interoperability is still a barrier to integration.

Good feedback, no pushback. Mr. Bruner cites three things that he thinks made a difference at CPM in getting everyone in the shop to accept machine monitoring: (1) Make it clear to operators that managers can see the same data reports that they can. The reasons for collecting data and using it wisely to everyone’s benefit becomes clear. “It’s all about staying green. Monitoring is a tool that helps operators use their time more effectively,” Mr. Bruner says. (2) Start with production goals that are achievable. This instills the habit of taking actions that keep performance in the green. As users become more efficient by responding to the performance data, tighter trigger points on excessive setup time or production delays can be applied. Mr. Bruner likens this approach to training wheels on a bicycle. (3) Solicit and honor feedback. Some of the best suggestions for getting more choices for categorizing part rejects, setup delays or machine stoppages came from operators. Likewise, one operator spotted a way to change the part program to gain a faster cycle time on a long-running, high-volume job. This change, Mr. Bruner says, will save 900 hours over the rest of the year. Making the shop culture more proactive is an important benefit.

Overdrive on a Ferrari

Mr. Bruner sums up what getting machine monitoring has meant for his shop. “A machine like those in our shop can cost as much as a Ferrari. Machine monitoring is like adding overdrive to the Ferrari.”

Related Content

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More