Articles

February Income at Almost Lowest Level Since Recession Start

In February, real personal income excluding government transfers was 1.8% less than in February, according to the Bureau of Economic Analysis.

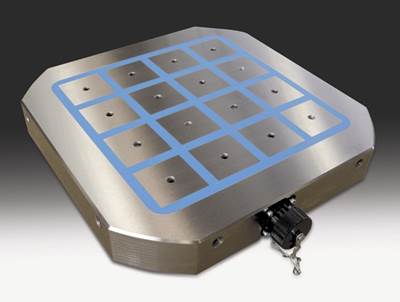

Read MoreZero-Point Magnetic Chucks for 5-Axis Milling

The Zero-Point system combines pallet changing and magnetic chucking into a single integrated unit.

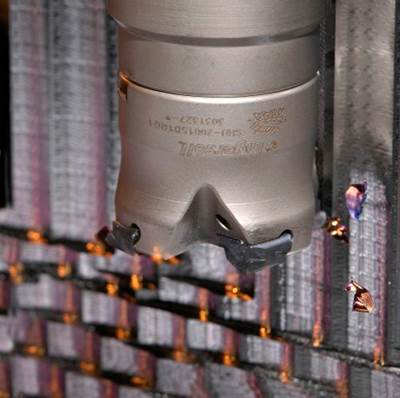

Read MoreTurn-Mill? How About Just “Mill”!

In a strange way, one of the most limiting features of a multitasking, or turn-mill, machine is the presence of the turning capability.

Read MoreVideo: Mill Turns Now, Too

Spanish machine tool builder Ibarmia offers a moving-column machine that has an interesting table-within-a-table configuration.

Read MoreSomebody Has to Do It

Since 2000, I have had the pleasure of visiting what I consider the prettiest trade show location in the world.

Read MoreHow To Choose A Plasma Cutter

Contributed by Hypertherm (West Lebanon, New Hampshire). The company designs and manufactures plasma cutting systems for use in a variety of industries such as shipbuilding, manufacturing, and automotive repair. Its product line includes handheld and mechanized plasma systems and consumables, as well as CNC motion and height controls.

Read MoreMachining Centers or Transfer Machines for High Volume Work?

Few would consider a machining center to be an overly “dedicated” piece of equipment.

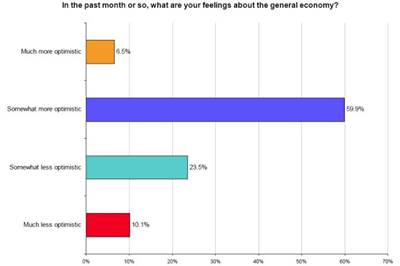

Read MoreBuying Mood and Optimism Bounce Back

These results from March indicate that respondents are beginning to feel more optimistic about our general economy.

Read MoreConsider Tool Capacity on Your HMC

Quick-change workholding made it plain that additional setup time savings would require a larger tool magazine.

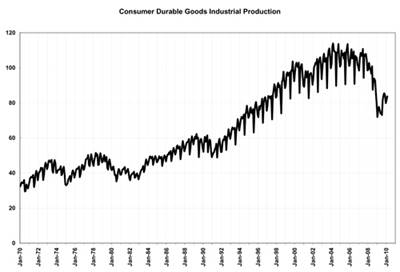

Read MoreFebruary Industrial Production up 10% but Trend is Flat

Consumer durable goods industrial production in February was up 10.0% compared to February 2009, but since August 2009 the index has been virtually flat.

Read More