Let Assembly Be The Inspection

This shop realized single-setup machining on a multitasking turning center, but there was still more efficiency to be found. When all of the part's machining had been consolidated, the shop realized that assembly operations could be performed at the same station as well.

Share

The next step beyond consolidating machining operations is consolidating manufacturing operations.

Specifically, the next step beyond a multitasking machine tool—one that machines a part complete in one setup—is to move assembly operations to the same station where the machining is performed.

That is what the Gardner Denver facility making Champion air compressors in Princeton, Illinois, recently discovered.

How did the plant discover this? Diana Delbridge, the operator of the multitasking lathe that now machines pistons in a single cycle, inspected every piston as it came off this machine. Based on this inspection, she would make tiny adjustments to program variables and CNC offsets to ensure that parts remained consistent. However, this inspection was just a proxy for assembly. The reason she inspected parts was to confirm that they would fit correctly in the assembly process performed elsewhere in the same facility. Was this efficient?

It was not. Rather than spend time on inspection, Ms. Delbridge could just as well spend her time on assembly. In short, she could let the assembly be the inspection. If pistons started to fit too snugly in the assembly, then this would cue her that it was time to adjust the machining process.

The only new resource needed to achieve this further consolidation is a robot to load and unload the machine tool. Once the plant installs this robot (which will happen very soon), Ms. Delbridge won’t have to interrupt assembly to perform this task. One of the plant’s most productive employees will then be empowered to provide even greater value still.

One Operator, One Shift

William Glass is the plant’s senior manufacturing engineer. He says the development described above represents one of the lessons of multitasking—that successfully consolidating operations can lead to even further consolidation. And this was not the only surprise, he says. Another surprise was that machining this part in one setup was even possible at all.

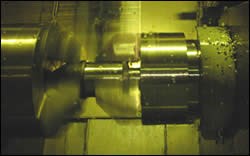

The plant used to produce pistons on four machine tools run by two operators per shift on two different shifts. Mr. Glass knew a more sophisticated process could achieve greater efficiency than this, but he assumed that more than one machine tool would still be needed. The piston’s diameter features a set of opposing bores that not only locate relative to one another, but also locate relative to an ID groove. He thought these critical holes would continue to demand a separate machine. Instead, the machine that the shop purchased—a Eurotech Elite 735 SL-Y turn-mill machine—proved capable of doing the job. When the machine’s main spindle isn’t spinning, it becomes a C axis with sufficient repeatability to allow accurate machining of the opposing bores. As a result of being able to machine the pistons complete in one handling in this way, the required quantity is now produced by just one operator on one shift.

Speed Options

Ms. Delbridge explains that the machine has also improved the process as a result of its speed. Not only have tasks been consolidated; some of the tasks are now performed faster and better. A rough turning operation formerly limited to carbide tooling is now performed with a ceramic insert at 3 times the previous speed, she says. Similarly, the machine’s 8,000 rpm for rotary tools makes carbide drills cost-effective for a series of holes that were previously machined on a drill press using high speed steel tools.

But the speed can also be applied to make the process more flexible, Ms. Delbridge says. Grooving was once performed with a single plunge, meaning the insert had to be changed whenever the dimensions of the groove began to drift too far. Now, she takes advantage of the heightened speed to quickly perform grooving using two overlapping plunges—one for one wall of the groove and one for the other. If groove dimensions begin to drift, she can get another 100 or so good pistons out of the same insert just by widening the stepover variable between the two plunges.

Overcoming Offshoring

Quality has improved as well. “These are the best pistons we’ve ever made,” Mr. Glass says. This fact points to one other lesson the shop observed by consolidating operations—that the same impediments holding down efficiency are likely to hold down quality as well. Improved quality can be a natural side effect of process streamlining.

However, the quality gains here represent something more than just a side benefit. The gains serve to further demonstrate a case the plant has been making through various process improvements. It is not just the piston machining that’s changed here—the same kind of process improvement is being done throughout the plant. Parent company Gardner Denver has plenty of options for manufacturing, Mr. Glass says, and his plant faced the real possibility of losing work to sources in China or India.

But the plant is now gaining work instead, and the piston process illustrates the reason why. As a result of the investment in both retooling and rethinking its processes, this plant has been able to beat the offshoring alternative by allowing its production employees to deliver even greater value.

Related Content

Custom Motorcycle Parts Made Here: Video Tour of a Family-Owned CNC Machine Shop

Lee Wimmer invited us to tour his second-generation family-owned machine shop in Perkasie, PA. This video explores the production processes behind precision-machined parts for both Wimmer Custom Cycle and LS Wimmer Machine Co., and shows how ingenuity and determination are still at the heart of American manufacturing. Today, both companies are now managed by Wimmer’s three sons.

Read MoreFacilitating Lean Manufacturing Through Modularity

Knowing how to subdivide machines and jobs has enabled Danobat to create a lean manufacturing process that improves its lead times by up to 25%.

Read MoreSecond B-Axis Improves Efficiency of Swiss-Type Machining

A highly stable, fully programmable B-axis on the subspindle of Nomura DS’s 20J3XBTC enables users to more quickly machine complex parts complete.

Read MoreA History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreRead Next

The Post-Machine-Shop Process

Making the transition from batch production to a build-to-order strategy meant removing the kinds of barriers that separated machining from the rest of manufacturing.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=970;quality=90)