Published

LED Lights Offer Flexibility, Energy Savings

New LED lighting has provided better-quality illumination and substantial energy-cost savings at this precision machine shop.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

A new LED system has made Creed Monarch’s future a little brighter, both literally and figuratively. The precision machine shop reports that compared to its previous high-pressure sodium (HPS) lighting, the Intelligent LED Lighting System from Digital Lumens (Boston, Massachusetts) has provided not only better-quality illumination that can be adjusted precisely and as-needed, but also substantial energy cost savings and reduced maintenance.

Established in 1953, Creed Monarch is a contract manufacturer in New Britain, Connecticut that serves customers in industries ranging from automotive to aerospace to munitions and hardware. Work ranges from single-piece jobs to high-volume production runs. More than 260 people work at the company’s 140,000-square-foot manufacturing facility, which operates five days a week on a 10-12 hour schedule.

Machining cells and individual workstations are organized according to the production requirements of specific work orders. As work fluctuates, various areas might be unoccupied at any given time. Although management had recognized the potential for energy savings by turning off or dimming lights in these areas, the shop couldn’t take full advantage of that opportunity with its previous 400-watt HPS system. During an approximately 10-year-long search, the shop considered a number of alternatives, including both fluorescent and other HPS systems, only to determine that none met its needs. “Time and again, two essential ingredients were missing: integrated sensors and centralized control,” explains Paul Stawarz, facility manager. “As machinery is brought on- and off-line to fill customer orders, we knew we would leave significant savings on the table if we could not manage lighting behaviors individually, by zone or facility-wide.”

Years of searching and consultation with Energy Services Group, a Marion, Connecticut-based firm specializing in high-efficiency replacement lighting for industrial businesses, eventually led the shop to Digital Lumens’ Intelligent LEDs. This system consists of wirelessly networked LED fixtures with integrated occupancy sensors, all managed from a central point via the developer’s LightRules software. Mr. Stawarz and the rest of the management team at Creed Monarch cite the following as the system’s primary benefits:

Improved Light Levels. The shop reports that the color rendering index (CRI) LEDs provide sharper colors and better light levels than the previous system.

Control and Flexibility. The ability to adjust lighting as-needed throughout the facility, even on the level of individual fixtures, enables the shop to fine-tune lighting to match changing work patterns and to safely eliminate unused light. For example, using LightRules software, the shop can adjust timeout, dimness and other settings on individual fixtures or groups of fixtures to more brightly illuminate certain workstations, dim the lights in less-traveled aisles, or have the lights behave differently according to the time of day (dimmer lights for night cleaning shifts, brighter for production shifts). Regardless of what a given fixture is programmed to do, built-in occupancy sensors ensure safety by turning the light on when someone enters the area.

Many of the fluorescent models the shop considered before adopting the Intelligent LED system were equipped with add-on sensors. However, these systems lacked the desired level of flexibility. For example, many restricted time-out settings (how long a fixture stays on after an area is vacated) to a limited number of predefined intervals. The Intelligent LEDs have no such restrictions, and Mr. Stawarz adds that he likes the fact that the system’s sensors are an integral part of the design. Additionally, many fluorescent alternatives would have forced the shop to lock in fixture settings at installation. Moving fixtures and changing sensor settings after installation would require hiring outside lighting engineers. In contrast, the Intelligent LEDs can be grouped and re-grouped as-needed for changing production conditions, and sensor settings can be easily adjusted in LightRules, the company reports.

Improved reliability. Typically, turning an HPS or fluorescent fixture on or off reduces both fixture longevity and lamp life. These fixtures also continue to consume electricity in the off state. According to Digital Lumens, that’s not the case with the Intelligent LED system. Rather, off really means off; dim means whatever level management defines; and lighting instantly turns fully on when an occupancy sensor is triggered. The company adds that with independent lab-rated lifetimes in excess of 50,000 hours without re-lamping or re-ballasting, the LED system requires less maintenance than other alternatives.

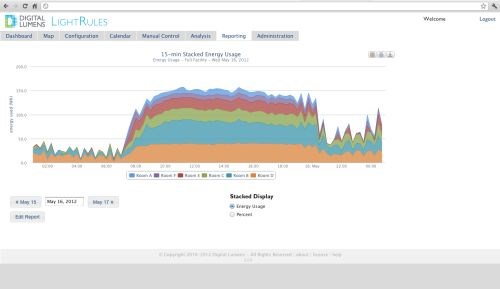

Energy Savings. For Creed Monarch’s bottom line, the most direct impact of longer-lasting, individually-controlled fixtures is energy cost savings resulting from reducing or eliminating unneeded lighting. LightRules software contributes to further cost savings by providing integrated reports that document when peak usage occurs, where activity is concentrated in the facility, and other information that helps the shop further tweak lighting delivery. In all, the shop is currently realizing energy savings of approximately 75 percent compared to the previous system.

Moreover, management expects to achieve 90-percent savings within the next year as it continues to fine-tune lighting delivery. Projected energy savings are 1,036,699 kWh per year, or $108,436 at $0.1046 per kWh. At that rate, the company is on track to secure a rapid payback while also taking advantage of power utility rebates and energy efficiency incentives.

“We saw countless proposals and new technologies through the years, but Digital Lumens was the first to address our need for control of individual fixtures,” says Richard Creed, President of Creed Monarch. “We are able to dim, shut off and customize light levels without affecting the life or performance of the light. We want to see Digital Lumens succeed with us, and we are looking at this as a long-term relationship.”

Read Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

Workforce Development

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)