Laser Marking Basics

Learn about the various marking processes that lasers can perform.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

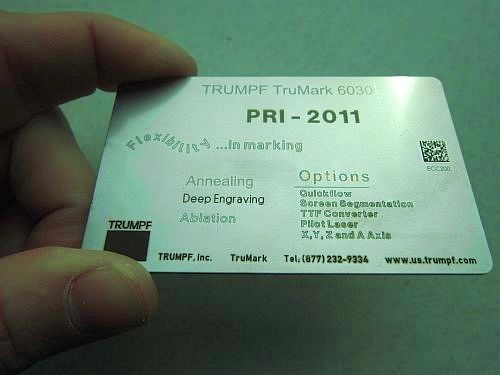

I picked up this sample at the Performance Racing Industry show. It shows the various types of marking processes that a Trumpf 6030 laser can perform.

To color plastics, the laser beam heats the surface locally, which causes some materials to become darker and others lighter in color depending on the material composition. In blackening, soot particles are generated that show the inscription in dark letters on lighter-colored plastic. To make dark plastics white, foamed marking is used whereby the laser beam melts the workpiece material locally. Small gas bubbles form in the molten material that increase the material’s volume creating foam. The processed area appears much brighter than the surrounding material and, in some cases, the marking is raised above the surface of the workpiece.

Related Content

-

How to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)