Know About the “Headless Bolt” Fixturing Alternative?

This fastener enables fast workpiece change-overs compared to conventional bolts. Its compact design means there’s less cutter interference, too.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

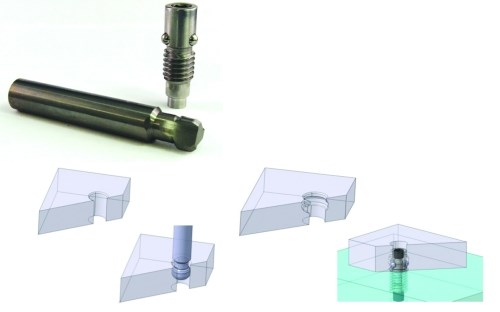

Loc-Down units install in tapped holes in a subplate. The workpiece (shown here in gray) requires mating holes that have a machined internal groove to accommodate the units. Holding force is provided via the unit’s ball-lock mechanism.

Installing and removing conventional bolts used to secure workpieces to subplates can be time-consuming. Plus, protruding bolt heads often interfere with the cutting tool, preventing it from accessing all workpiece areas that require machining. As a result, Mitee-Bite has developed its “headless bolt” Loc-Down system so users can quickly attach and remove workpieces from subplates. Not only does this system enable faster workpiece change-overs compared to conventional bolts, but there’s less cutter interference thanks to its compact design. Learn more.

Related Content

-

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

-

Fixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

-

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

.jpg;maxWidth=300;quality=90)