Iscar Leader Describes Tool Technology for Machine Shops Acting on Data

As more sophisticated insight into machining performance reveals opportunities for efficiency gain, the value of tooling choices that save time will become increasingly clear.

Share

Takumi USA

Featured Content

View MoreThe promise of Industry 4.0 is great news for the adoption of advanced cutting tools. The reason: In interconnected manufacturing systems in which comprehensive data reveal the performance of the system, the impact of an advanced tool becomes clear.

Jacob Harpaz, president and CEO of IMC, the parent company to cutting tool maker Iscar, repeatedly stressed the connection between Industry 4.0 and cutting tools in a recent day-long series of presentations in which he introduced the many new and upcoming Iscar products to about 600 distributors and other salespeople representing these tools. Iscar organizes an event like this about once every five years, and this year, the move toward data interconnectivity in manufacturing is one the most encouraging developments Mr. Harpaz sees.

Historically, the lack of clarity about manufacturing performance has been the main impediment to shops embracing high-end cutting tools. Tools typically account for just 3 percent of the per-piece production cost of a machined part. However, a tool's price tag is more visible than its benefits. This fact leaves manufacturers frequently pursuing cost-saving steps that have little impact. For example, at 3 percent of unit cost, finding tooling that is one-third less expensive will only cut the per-piece part cost by 1 percent. Something similar is true of tool life: Even doubling tool life will only cut cost per part by 1.5 percent. However, finding tooling that provides for significantly faster machining or reduced non-cutting time enables each unit of machine and labor time to deliver more parts, likely cutting the cost per piece by 10 or 15 percent.

This argument makes sense in the abstract. The problem is, it can be hard to marshal the data to prove this case as it applies to a specific tool in a specific cut. That is where Industry 4.0 comes in. We are moving into a world in which manufacturing systems increasingly do marshal data such as this, and manufacturers increasingly make use of it.

“The companies that are good at collecting, analyzing and acting on data will be the leaders,” Mr. Harpaz says, and he expects Iscar will serve them via tools able to cut faster or reduce setup, along with inventory systems supporting the aim of 24/7 machining. The company’s “Logiq" product introduction aims at this, and “machine intelligently” is the company’s tagline for this idea.

In his talk to Iscar representatives, Mr. Harpaz spoke for the better part of 10 hours to explain many classes of new cutting tool products—too much to summarize. But here are examples of some of the kinds of tooling that will help manufacturers ready to refine their processes within increasingly data-driven shops:

- Exchangeable-head tooling. The company’s Multi-Master line is an example of this. The milling-tool family combines a replaceable carbide tip with a steel shank that remains in place in the machine. Among other benefits, this concept of quickly and repeatably changing the tool’s tip provides a time-saving alternative to solid-carbide tools requiring regrinds and repeated tool setting. Much of the success of this type of tooling is being realized on live-tool turning machines, Mr. Harpaz says. In drilling, Iscar has developed exchangeable-head tooling as small as 4 mm in diameter.

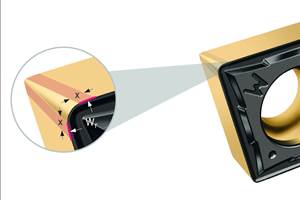

- High-feed mills. The use of high-feed mills is now commonplace, Mr. Harpaz says, to the extent that more conventional tools for milling steel at heavier depths and slower feed rates have become dated. Iscar has expanded its tool offerings available in a high-feed geometry, including a solid ceramic end mill.

- Through-tool coolant delivery. Also seeing expanding application are the tools for various machining operations that deliver coolant at high pressure through the tool to where it can most benefit the cut, often by driving chip evacuation.

- Vibration reduction. Tooling applied at long extensions—for boring, milling, grooving—increasingly features built-in moving counterweights that inhibit vibration for faster and more predictable cutting.

- Tool management. The company has expanded its Matrix line of tool-management systems, offering shops and plants various levels of sophistication for stocking tools and related hardware items, tracking these items, controlling access to them and providing for automatic replenishment as this inventory is used. These systems provide for interconnectivity between the shop and the tool supplier, Mr. Harpaz notes, delivering what is perhaps the most important tool-related benefit of all: the assurance that the shop will have that tool in its possession precisely when the tool is needed.

Related Content

Tungaloy Expands Threading Tool Insert Offerings

The TungThread indexable threading tool series is designed for applications including general parts that are machined in CNC lathes and small precision parts in Swiss-type automatic lathes.

Read MoreWalter Turning Grades Feature Curved Wiper Cutting Edge

The FW4 and MW4 positive wiper geometries provide a wiper action that can reportedly be used to reduce machining time by using double the feed rate.

Read MoreSandvik Coromant Turning Tools Enable Y-Axis Turning

The company has developed two new tools to support Y-axis turning: CoroTurn Prime and the CoroPlex YT twin-tool.

Read MoreKyocera Turning Grade Provides Tough Cutting Edge

The Megacoat Tough coating combines a wear-resistant layer on the surface adhered to high-content CBN, which provides greater fracture resistance when encountering interruptions.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More