Investing in Tech Is a Strategy, Figuring ROI Is a Strategic Tool

This short article by Jeff Reinert, president of Index Corp., outlines the multi-step process for justifying an investment in the latest CNC machining technology. Calculating the return on investment (ROI) is a useful step in this process, but only one of the factors a manufacturer must consider in the decision to buy a new machine. Read the article here.

Share

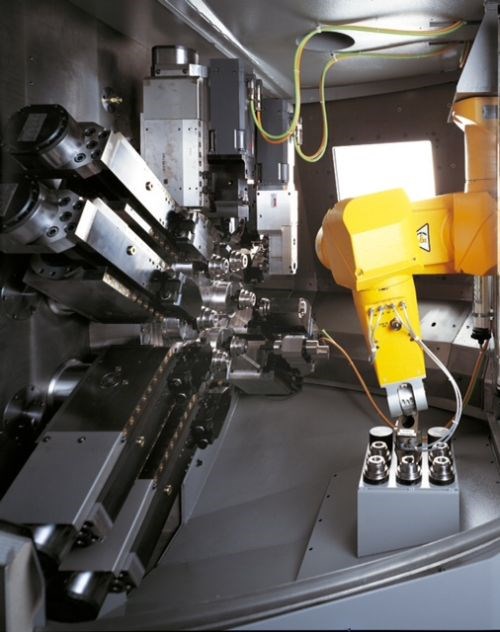

Why invest in new CNC technology that seems unfamiliar, even a little scary? Jeff Reinert says that a bold approach to justification can show shops that they need to jump in if they want to compete.

This short article by Jeff Reinert, president of Index Corp., outlines the multi-step process for justifying an investment in the latest CNC machining technology. Calculating the return on investment (ROI) is a useful tool, but only one of the factors a manufacturer must consider in the decision to buy a new machine.

Reinert identifies three main steps:

- Understand your machining costs and evaluate impact of a faster, more capable process.

- Understand potential benefits of the latest CNC technology (Reinert lists eight measurable ones as a start).

- Understand the costs of older equipment (including operator skills that may vanish).

After taking these steps, calculating ROI can be a concise and useful analysis to back up a decision. However, as Reinert explains, ROI is not the same as profitability and competitiveness. His advice puts the ROI calculation in perspective.

Related Content

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

-

How I Made It: Amy Skrzypczak, CNC Machinist, Westminster Tool

At just 28 years old, Amy Skrzypczak is already logging her ninth year as a CNC machinist. While during high school Skrzypczak may not have guessed that she’d soon be running an electrical discharge machining (EDM) department, after attending her local community college she found a home among the “misfits” at Westminster Tool. Today, she oversees the company’s wire EDM operations and feels grateful to have avoided more well-worn career paths.