Few machining enterprises boast a flagship product with the “cool” factor of the Argo, an amphibious, all-terrain vehicle (ATV) that has been used in exploration, search and rescue, industrial and recreational activities since the late ‘60s. However, during the past five years alone, manufacturer Ontario Drive and Gear (ODG) has invested more than $10 million in new equipment to support a more significant portion of its business: the gear manufacturing services it began to provide in 1985 to capitalize on lessons learned from designing and manufacturing the Argo’s transmission.

Among that equipment is a group of machines that has had particularly far-ranging effects on gear manufacturing at ODG: four EMAG inverted vertical turret lathes (VTLs) for which automation is not an accessory, but an integral part of the design. These machines have been a primary driver behind a move toward a single-piece flow, cellular manufacturing strategy that has significantly improved throughput, flexibility and part quality for a critical portion of the company’s product line.

The 80/20 Rule

Now celebrating its 50th year in business, ODG operates two plants in New Hamburg, Ontario: one dedicated to ATV production, the other for the gear and transmission side of the business, which includes gear and system design, transmission assembly and performance testing. ODG Gear moved into the latter facility in 2000. It spans 56,300 square feet of climate-controlled manufacturing space that houses an array of CNC gear hobbers, shapers and gear grinders as well as CNC lathes and mills. The plant’s 115 employees work to produce more than 850 distinct part numbers in quantities ranging from one to 75,000.

Approximately half the equipment on the plant floor is used for operations prior to heat-treating, and the other half is dedicated to post-heat treating. The four EMAG VTLs shine in both roles, says Joel Wright, general manager at ODG. They are currently paired off into two cells for pre- and post-heat-treat turning operations, respectively. The machines’ primary work consists of relatively small, flat, carburized steel gears that measure no more than 2 inches thick and 6 inches in diameter. These components represent only 40 different part numbers. However, as is the case for many manufacturers, those 40 different parts account for a significant portion of the gear division’s work. “Overall, about 20 percent of the parts make up 80 percent of the volume here,” Mr. Wright says.

Stop and Go

The importance of this work made it a prime target for efficiency improvements. Nonetheless, the sequence of operations remains essentially the same as before the VTLs were installed. Production begins with two turning operations (“Op 10” and “Op 20”), one for each side of a gear blank. The parts proceed to broaching for creating any necessary internal splines and then on to hobbing for forming of the gear teeth. After deburring, they are sent out for heat treating before returning to the plant for hard turning on each side and final finish-grinding operations.

Now, however, the time required for this entire process is measured in hours instead of weeks. Mr. Wright explains that the primary difference isn’t the production sequence, but a new strategy for how the parts flow through that sequence—a strategy facilitated by the VTLs. Prior to installing these machines, a batch-and-queue-style approach to production made inefficiency virtually inherent to the process. “We’d run through initial turning operations on a batch of 600 or a thousand or so, then stop and move everything on to the broaching machine, and so on down the line,” Mr. Wright says. “It was always one man, one machine, with manual loading and unloading. As strong as any operator-machine combo might have been, the fact that everything was always totally operator-dependant was a major drawback.”

Even justified breaks for coffee or lunch could directly affect cycle time. Strict statistical process control (SPC) requirements that dictated frequent in-process inspections did little to help matters. Additionally, while errors were by no means common, simple mistakes could have ripple effects down the line. For example, Mr. Wright says he can recall a few instances of operators misloading parts in the chucks of the horizontal lathes used prior to the VTLs.

Letting it Flow

ODG purchased its first EMAG VTL, a VL3 with an 8-inch chuck, in 2010. At the time, the company was in the midst of replacing aging equipment, a routine that recurs every few years, says Ed Das, process development manager. As it turned out, design elements of the VL series sparked a revamp of the problematic batch-and-queue production process. By the end of 2011, the shop had integrated three VL5s, which feature 10-inch chucks. “Not that the EMAGs got us there on their own, but their compact footprint and integrated automation led us to adopt a more cellular approach to manufacturing,” Mr. Das says.

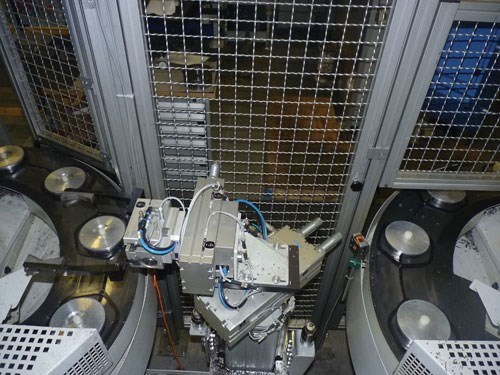

That approach begins with initial Op 10 and Op 20 soft-turning operations, each of which is conducted on a separate VL5. All VL series machines are equipped with integrated conveyors that transport parts to and from the workzone. Unlike the previous process, which required multiple, time-consuming loading/unloading steps for each gear blank, operators can stage as many as 14 parts at a time on the first VL5’s conveyor. This is fast and easy thanks to hexagonal carrier prisms at each station that ensure consistent loading, Mr. Das says. As long as a part is placed somewhere in the prism, he explains, it will nest within the corners created by the hexagonal shape regardless of its shape or size.

Inside the workzone, the machine’s vertically-oriented spindle descends from above to grip parts and present them to a 12-station, disc-type tool turret in the machine base for Op 10 turning. Vertical construction ensures chips and coolant fall away from the tool and workpiece, Mr. Das notes. Then, parts move automatically to the second VL5’s conveyor via a simple flip station that joins the two machines. When the parts cycle out on the second machine’s conveyor after Op 20, the operator moves them to a different conveyor that leads to broaching, hobbing and other downstream processes, sometimes performing an inspection at a gaging station before doing so. “The parts don’t stop, they just move from process to process,” he says. “The programs aren’t running any faster, but the automation and the consistency of the machines, as opposed to an operator, allows for production rates that are typically 40 percent faster than before. It just spits parts out like popcorn.”

Perhaps just as significant is the fact that machine-integral automation enables the company to break down this dedicated cell at will to suit changing production requirements. For comparisons’ sake, Mr. Das cites the example of a twin-spindle turning center. Passing parts between the main and subspindle could provide the same benefits as the flip station that joins the VL5s. Likewise, a gantry loader or similar accessory could play the same role as the integrated conveyors. However, this solution would lack the advantage of having independently operated spindles that can be easily separated and moved to different sections of the plant without losing automated capability. As Mr. Wright puts it, “We can combine and re-combine them like Legos.”

The VTLs have also contributed to improved part quality. Ultimately, that’s just as important as time savings—although in this case, the two go hand-in-hand, Mr. Wright says. In a direct sense, the rigid construction of the VL3 and VL5 used for post-heat-treat turning enable tolerances of +/- 0.0005 inch, as opposed to +/- 0.001 inch with previous systems. Also notable, however, are the indirect quality improvements stemming from the move toward automated, single-piece flow. This enables operators to spend less time tending to the process and more time inspecting parts. “If you can make a better gear blank, you will ultimately have better datums, and you’ll do a better job of hobbing, gear grinding and so on down the line,” Mr. Wright concludes. “The EMAG machines have dramatically improved our capability in that respect.”

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)