Introduction to Digital Depth Gage Styles

There are many digital calipers specifically designed as depth gages. They share some common features but come in a variety of styles. Here are several to consider.

Share

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreThe first depth gages consisted of a simple scale with a sliding perpendicular beam as the reference. As the need for higher resolution and precision increased, these were largely replaced by Vernier devices and micrometer depth gages. Today, both Verniers and micrometers have been replaced by digital versions of the depth gage, offering long measuring range and versatility.

The most common caliper-style depth gage is based on a 6-inch/150-mm caliper that has a depth rod or bar built in. The end of the caliper can be used as a reference stop, but adding the accessory depth bar fixture to the beam of the caliper can magically extend the capabilities of the run-of-the-mill 6-inch caliper to a fully functioning and perfectly adequate depth gage.

The fact that a depth gage is based on a modern caliper gives it a lot of capabilities. Most modern calipers have features that are inherently standard. These features include a reference system built into the scales by which the display turns on with the slightest movement and never forgets its last reference setting so that the gage can be picked up and used immediately without having to be re-zeroed. Calipers are protected against high levels of liquids and dirt. And finally, these calipers often are provided with some form of data output capability, whether through a wire or integrated wireless transmitter, for data collection.

However, there is a range of calipers that have been specifically designed as depth gages, sharing the same type of reference bar as their cousin, the dial depth gage, but offering more capacity and capability. These portable hand tools start at 1 inch (25 mm) in length and can be designed to span 24 inches (600 mm) or more.

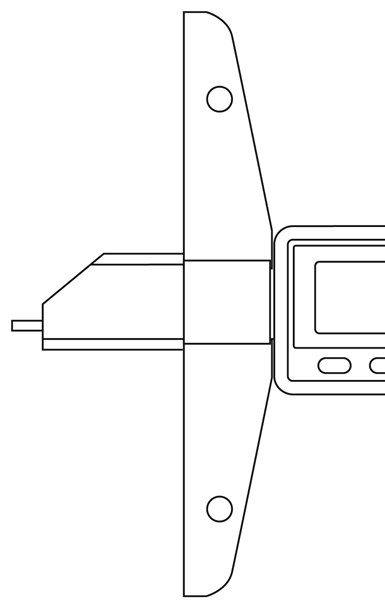

Figure 1.

Portability

Portability is the claim to fame for the small and valuable depth gage seen in Figure 1. About the size of a classic flip lighter, the device generally has a 1-inch (25-mm) measuring range. It fits perfectly in a pocket, ready to travel around the shop with their owner and check a part on the fly, ensuring a fixture is set correctly or performing any number of other useful checks. Its 0.08-inch (2-mm) rod contact also makes it easy to check the depths of some pretty small holes.

Double-Hooked

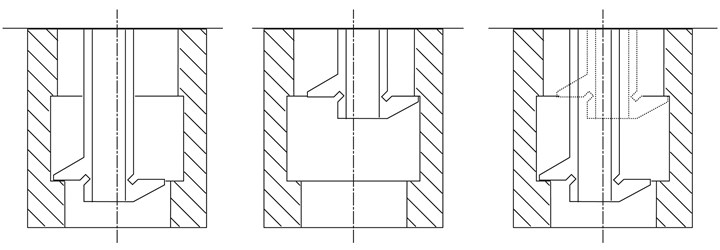

The type of double-hooked depth gage shown in Figure 2 has a pair of flats on the measuring end — one facing down on the measuring beam and a second opposite it facing up. These are ground to be on the same plain, giving the gage the unique capability of measuring opposing surfaces for distance while having to zero only on one reference point. Thus, if you need to measure, for example, the width of a groove cut into an inner diameter or the distance between two grooves, this double-hooked depth gage is the solution.

Figure 2.

Figure 3.

Deeper Measurement

Probably the truest of depth gages is one in which the whole beam of the gage acts like the sensitive contact, as seen in Figure 3. These gages can be provided with capacities of up to 20 inches (500 mm) of depth. For such depths, the beam of the caliper, which acts as the measuring contact, adds a degree of stiffness to ensure that any flexure that may influence the measurement is kept to a minimum. While the end of the beam is tapered and has a small enough surface to act as a reliable measuring contact, it also has a small mounting hole for a 0.060-inch- (1.5-mm-) diameter contacting pin held in place by a locking screw. This feature allows the beam (with contact pin in place) to find and measure small dimples of bottom grooves cut into a blind hole, for example.

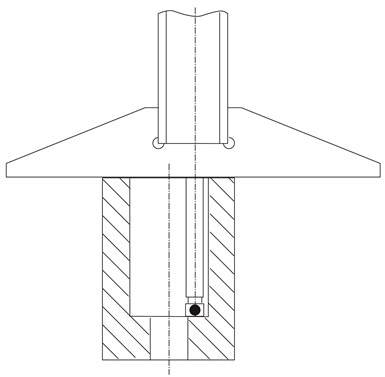

Figure 4.

Small-Hole Measurement

Another class of depth gage, as seen in Figure 4, is designed for small holes. These employ a fairly substantial depth rod, which slides out of the depth beam. This rod is large enough in diameter to allow for exchanging contacts having a 2.5-mm thread, which is common for many gaging applications. Thus if one needs to measure down into a deep, small-diameter hole or a narrow land in a deep hole, this may be the style for you. With a disc-shaped contact, even groove location can be measured. However, don’t forget to take into account the thickness of the disc contact when making a groove width measurement.

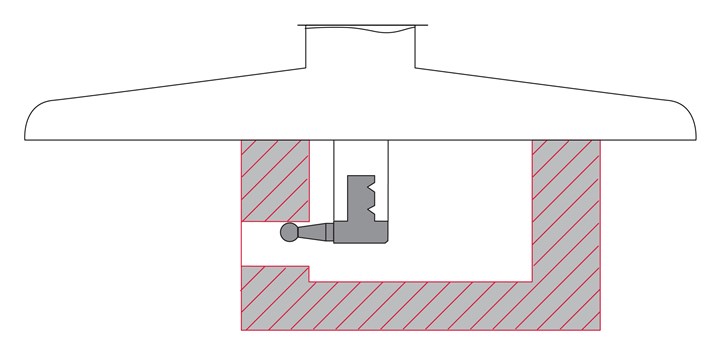

A More Robust Gage

There is a class of large depth gages (20 inches/500 mm) that are pretty robust, equipped with an interchangeable shoe that acts as contact rather than screw-in contacts or pins attached to the beam. A standard shoe, such as the double hook, allows it to function as noted above. But there are shoes to allow measuring of wide recesses and grooves, small bores, offset measurements outside the center of the bore, or narrow front recesses, grooves and concave points, as seen in Figure 5. These large depth gages also have optional bridge extensions for broad-based support on large workpieces and for offset measuring outside the center of a large bore.

Figure 5.

Related Content

4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreThe Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreRead Next

Deep Thinking About Depth Gages And Their Evolution

A depth gage is a very common hand tool used to inspect the depth of holes, slots, counterbores, recesses or the distance from one surface to another. They are especially common in the tool and die industry.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)