Integrated Machine Arm Retrieves Cutters and Work

Although this machine tool builder sells itself on extreme precision, this system demonstrates attention to versatility and efficiency as well.

Share

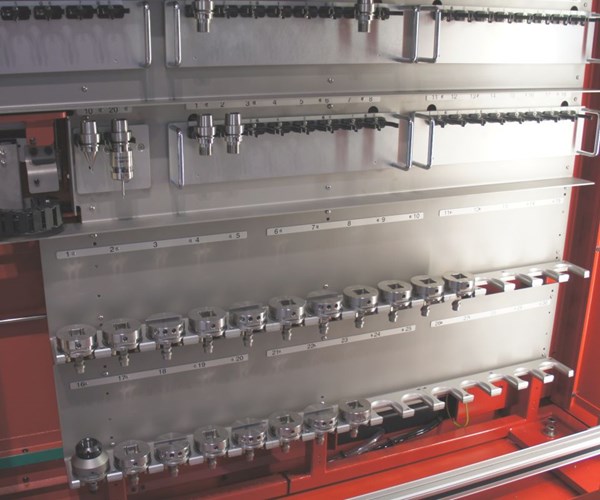

As demonstrated by this video of its Micro five-axis machining center, Kern Precision is happy to show off its machines’ ±0.5-micron positional tolerances and ±2-micron part accuracies (note how the cutter stays within the narrow, snake-like track even though the spherical portion of the part is off-center from the chuck).

Even with this option, one side of the machine remains open to accommodate external automation that can run in concert with the machine’s own part changer. Regardless, opting to store workpieces in the machine requires users to sacrifice some of the tool slots. In return, however, they receive automated part loading without any additional software, machine options, floor space or anything else. After all, the integrated arm doesn’t need to do anything differently to retrieve work versus cutting tools. And, there’s no reason a separate robotic arm or other automation can’t be employed at the same time. The only requirement is that the user choose the Micro’s five-axis configuration rather than its three-axis configuration because the worktable must tilt a full 90 degrees to interface properly with the arm. As an added benefit, that 90-degree motion can serve to dump any stray chips.

This system isn't the only feature of the Micro that strikes me as unusual. For instance, the machine’s entire axis structure is aluminum, not steel, and the temperature-management system relies on an external rather than an internal chiller. Even the workpieces themselves are chilled via a system underneath the table that employs both water and oil. For more, visit the builder's website.

Although the machine’s toolchanger holds nearly 200 tools, it can be configured with only 90 slots instead. The remainder of the space can be dedicated to as many as 30 palletized workpieces.