Indexers Are Enabling

In this shop's production machining environment, the workforce must be extremely flexible and workholding must be extremely rigid.

Share

The town of Frankton, just to the northeast of Indianapolis, is not far from the center of Indiana. Cerden & Sons, an automotive parts supplier, is not far from the center of Frankton. And not far from the center of this shop is a three-machine cell dedicated to machining differential cases for a second-tier automotive supplier.

All three machines are CNC vertical machining centers. On two of the machines, these workpieces are machined on four sides, which makes indexing the part on a rotary indexer an effective way to access all four sides in a single setup. Problem is, some features are not on the indexer's center line of rotation, which means the thrust applied to machining these features can have serious consequences for the success of this operation. In this case, the off-center operations involve some rather heavy drilling, producing substantial torque loads that must be resisted in order to avoid deflection or tool chatter.

"We just had to find an indexer built and designed to handle these kinds of loads," says Keith Graham, president of Cerden & Sons, which was founded by his grandfather, Russ Cerden, in 1939. "Otherwise, we wouldn't have even quoted on this job."

Not being able to quote on jobs such as this is not a good thing for a shop like Cerden & Sons. It's precisely the kind of work that the company exists for—mid- to high-volume automotive parts production.

Competition for these jobs is intense. Cost pressure is high. Tolerances are 0.001 inch or less on many operations. But the work is steady if the shop wins the contract. The differential case, for example, has been running for more than a year now, three shifts per day.

And the equipment assigned to this job shows it. Maintaining the equipment mechanically is a constant priority, of course, but aesthetics is not. On one of the indexers, for example, the builder's logo is almost completely worn off. You can barely make out the red SMW on the side. One of the CNCs, the Lagunmatic 3516, has obviously been earning its keep over the years, but as Mr. Graham points out, what counts is "not how it looks, but how it how it runs." And these are some of the newer machine tools in the shop.

Productivity And Flexibility

Having a lot of older machine tools in the plant doesn't cause Mr. Graham the least bit of embarrassment. Most of them are not CNC. "Automated, computerized machine tools don't necessarily fit our production philosophy," he explains. "Economy and flexibility are the main issues here. Automation is expensive and not always as flexible as you might believe."

The answer is using manual machines as low-cost modules in flexible cells. The machine tools—various horizontal and vertical milling machines, drill presses, turret lathes, OD grinders, and so on—are arranged in cells, each machine dedicated to one or two operations. Workpieces are handed off from machine to machine by the operators. As many as ten or fifteen machines may be arranged to make up a production cell. The company owns more than 300 machine tools stored in warehouses in Frankton and nearby Alexandria.

"All of this equipment is paid for. We don't have to have it running all the time to meet a return on investment," Mr. Graham says. This means a cell can be allowed to sit idle without incurring a penalty, especially considering the very low investment it represents. For many of the production contracts that Cerden & Sons holds, parts are run only a few days a week or even only a few days a month.

"We can afford to leave everything set up for that job and simply move in the crew of operators when it's time to meet production goals," Mr. Grahams goes on to say. "Our people represent the most flexible and most capable part of our operation." About 120 are employed there, spread over three shifts.

Handling inspection routines is an area where this approach makes a lot of sense. Most contracts call for SPC (statistical process control) techniques to be used but the requirements vary widely from part to part, even feature-to-feature on the same part. The solution is to use manual gages and hand-held data collection devices, with detailed, step-by-step instruction sheets posted at each workstation. This minimizes costs but maximizes compliance. The shop routinely passes its supplier quality audits but as Mr. Graham points out, "You have to keep constant vigilance over the long haul. That's the nature of this industry."

A Case In Point

Although the differential case cell is exceptional in having CNC equipment, it follows the pattern of other production cells at this plant. The cell consists of three VMCs. A Lagunmatic 3516 and a Leadwell MCV-760AP face each other, performing identical operations in identical setups. A third VMC, a Hurco BMC 30HT/M, performs secondary operations in a shorter cycle time, keeping up with output from the other two machines.

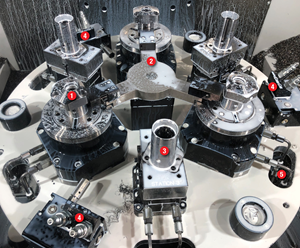

All three stations rely on rotary indexers but on the first two, indexing is an essential and more critical part of the production strategy. Parts are clamped in a box-type fixture secured to the head and tailstock of the indexer. Clamping and locating are provided on the top plate of the fixture, as shown in Figure 1, at right. The top and bottom plates have openings to access the top and bottom of the workpiece; the sides are open for machining the sides of the workpiece. The indexer rotates in 90-degree increments to provide four-sided machining. Figure 2 (below, at left) shows the other three positions.

Because indexing time is short and very accurate, once a tool change has been made it is faster to do all the work with that particular tool on every side of the workpiece that needs to be machined by that tool. There are ten tool changes and eight indexes on these first two VMCs.

Off The Center Line

The most severe operation in terms of load on the indexer is a series of 0.528-inch in diameter mounting holes drilled on the face of the part. The 12 holes form a bolt-hole circle 7.560 inches in diameter. A number of the holes lie off the center line of the indexer's rotary motion. Needed is a rotary indexer with adequate accuracy and rigidity. Accuracy is an issue because any indexing error is multiplied by the distance from center line. Likewise, rigidity is an issue because torque generated by drill thrust increases in proportion to the distance from the center line.

In this case, the shop chose the Accu-Rock rotary indexers from SMW Systems, Inc. (Santa Fe Springs, California). Jon Maynard of JM Precision Products, a local distributor, worked with the Cerden & Sons staff and recommended these indexers, providing advice and technical support along the way. All three machines are equipped with ET200 or very similar ET200V models, which have an 8-inch faceplate. Because of the size of the workpiece and its weight (about 30 pounds) and the size of the box fixture, all three machines are equipped with a heavy duty tailstock for outboard support.

"When we were engineering this application and preparing our quote, rigidity was our top consideration," Mr. Graham recalls. "As soon as we saw a rotary table of this size that was rated for 1,000 foot-pounds [of brake torque] we knew we could make a bid."

The key to the rigidity and accuracy of this rotary indexer lies in its face gear coupling design, which is free of the backlash found in worm screw systems typically found in rotary indexers. This design minimizes deflection and contributes to positioning accuracy, which the builder states is ±5 arc seconds or 0.001 inch at a 4-inch radius. Repeatability is given as 1 arc second.

Another design consideration that was important to Mr. Graham was that the face gear actuating mechanism does not require lifting the faceplate during indexing. "With the box-type fixture and tailstock, there's no convenient way to accommodate such a lifting motion, and this setup is essential to four-sided machining of the part," he says.

According to Mr. Graham, the key to the entire VMC setup is the accuracy of the index and of the positioning of each machine's worktable. "We are machining two 1.001-inch diameter holes to ±0.0005 inch on opposite sides of the diff case. These two holes must be in the same axis and parallel to the mounting face within 0.0005 inch," he explains. When taking the finish bore cuts on these holes, the indexer must first turn 90 degrees and the VMC table move 0.220 inch off center for the proper hole location. Then the indexer must rotate 180 degrees, and the VMC table must move 0.440 inch in the opposite direction to complete the other finish cut.

"Any inaccuracy in the indexing or the table positioning will obviously cause a defective part," notes Mr. Graham. "When our customer saw our process sheets prior to production startup, they were extremely leery of our ability to hold the desired tolerances. However, in the past year, we have shown excellent machine and process capability and the customer has been very satisfied."

Workpieces completed on either VMC are moved to the Hurco for secondary operations. A similar box-type fixture is set up on this machine, but operations are performed on only two sides in three indexes.

No Resource Goes Untapped

In a production environment, a shop such as Cerden & Sons has to be in the habit of looking for simple but effective ways to solve machining challenges and utilize existing resources as fully as possible. The rotary indexers provide an example.

"The differential case doesn't use the incremental indexing capability of these units," Mr. Graham explains, "but we recognized its value." (The indexers can be programmed to rotate bidirectionally in 5-degree increments.) "We soon saw an application for this capability on a shift fork we produce in small but repeat batches."

This workpiece, a steel forging, has three flats on the boss end, one at 0 degrees, one at +15 degrees and one at -15 degrees, as shown in Figure 3. "The indexers are perfect for the job. We work in short production runs on the Hurco—three cuts at 15-degree increments. It's fast and accurate," he says.

Is it a very glamorous application? No. But any visitor to this shop, or any visitor to Frankton, Indiana, for that matter, would agree that glamour doesn't count for much here. What counts here is what works, what is practical, what is dependable, long-lasting, rock solid.

Related Content

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MorePrioritizing Workholding Density Versus Simplicity

Determining whether to use high-density fixtures or to simplify workholding requires a deeper look into the details of your parts and processes.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)