Share

Sky’s The Limit… Or is it?

Aerospace, as an industry, gets a lot of attention every IMTS, and for good reason. Aerospace parts tend to be complex, and they often use difficult-to machine materials such as titanium and Inconel and frequently require more advanced technologies such as five-axis machining and additive manufacturing (AM).

With so much advanced technology involved in the production of aerospace parts, it is no wonder that IMTS 2022 has numerous conferences and booths that manufacturers working in the industry will find helpful.

A Confluence of Conferences

One area of the show that is rife with aerospace content is the conferences. These conferences give successful manufacturers the chance to share their experiences with IMTS visitors, providing insights into various approaches to manufacturing.

One conference to look out for is Titanium and Inconel Machining On a Grand Scale. Taking place on Wednesday in the West Building (W193-A), the event will have WFL Millturn Technologies Sales Manager John Kelly speaking on the uses of millturn machines in producing aerospace parts.

The Additive Manufacturing Conference includes numerous talks that specifically discuss the use of AM to produce aerospace parts. On Thursday, for example, the AM Conference will present a talk by Norsk Titanium called “Industrialization of Metal AM: Meeting Cost, Quality and Scheduling Expectations.” In it, Norsk CTO Carl Johnson will discuss his company’s approach to using AM to produce aerospace parts at full production levels. Find it, along with the rest of the AM Conference, in the West Ballroom in the West Building.

Other conferences cover specific challenges faced by producing certain kinds of parts, such as Next Generation in Continuous Generating Grinding of Aerospace, ICE, and EV Gears, presented by Norton Saint-Gobain Abrasives Corporate Applications Engineer Spencer Artz. This talk (taking place in the West Building W192-A) will discuss how grinding wheels are meeting the challenges posed by more difficult applications in aerospace and electric vehicle gears.

Additionally, aerospace manufacturers may find value in Layout and Planning Techniques for 5-axis Machining Centers (West Building, W193-A). As the name suggests, this conference focuses on how to develop a plan for five-axis machining in order to maximize your ROI. The speaker will be East at Jergens Technical Sales Manager Jack Rushlander, who will take visitors through a complete planning process in SolidCAM, from raw material to finished part.

Technology To Watch Out For

Of course, aerospace manufacturers have more than just conferences to see. The South Hall is where visitors can find the majority of CNC machines specializing in metal removal. For aerospace shops looking to grow, this is where you will find five-axis mills, millturn machines, multi-spindle machines, and grinding machines.

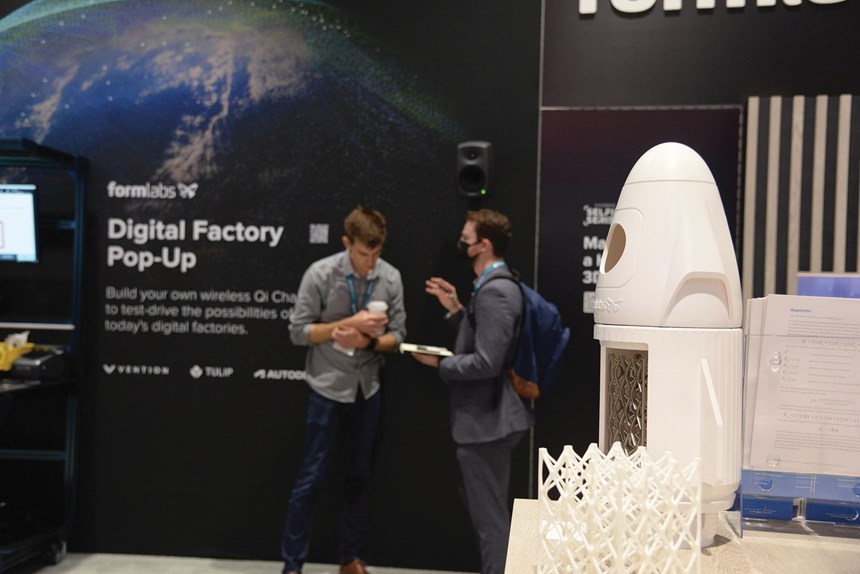

Over in the West Hall, visitors can find plenty of other companies that serve aerospace manufacturers. In addition to the tooling companies who sell specialized cutting tools for aluminum and titanium parts, this is where more additive manufacturing companies are located.

Of course, plenty of companies throughout the show have technology and expertise that is perfectly suited for aerospace applications, so be sure to explore the floor!

Related Content

Going Hands-On with Heidenhain and Acu-Rite Solutions

Heidenhain and Acu-Rite Solutions are offering several hands-on experiences at their booth this year, as well as internal components that reduce energy use.

Read MoreTrak Machine Tools Lathes Offer Compact, Heavy Duty Performance

IMTS 2024: The Trak TC2 and the Trak TC820si are compact lathes designed for production applications.

Read MoreSMW Autoblok Workholding, Automation Solutions Optimize Milling, Grinding Operations

IMTS 2024: SMW Autoblok presents the WPS XL for milling, measuring and grinding operations with five-axis and large part workpieces, as well as several products from its electronics and automation line.

Read MoreKeyence Multi-Sensor Measuring System Targets Quality Control in Metrology

IMTS 2024: Keyence introduces the LM-X Series Multisensor measurement system for high-performance measurement, automated inspection processes, accuracy and quality control.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)