Hybrid Combines High-Speed Milling with Powder-Bed Additive Mfr.

A new hybrid machining center from Sodick integrates high-speed machining with direct metal laser sintering (DMLS).

Share

Most hybrid machine tools rely on laser deposition to provide additive manufacturing capabilities. This strategy uses an additive head that sprays and heats metal powder to grow a part or its features.

In its OPM250L hybrid machine, Sodick takes a different approach. This machine tool combines high-speed milling via a 45,000-rpm spindle with direct metal laser sintering (DMLS), a powder-bed process that uses a laser to fuse metal powder layer by layer.

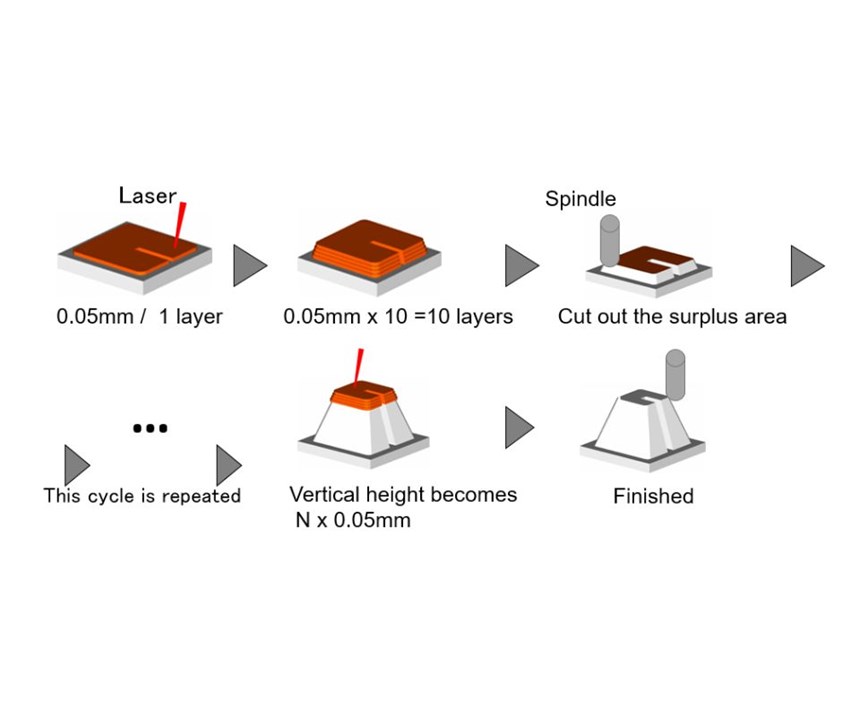

The machine’s additive process begins with a base plate the is coated with a thin layer of metal powder. A 500-W fiber optic laser sinters the metal powder in layers 50 microns thick. After 10 layers have been built up, the machine makes a pass with the spindle to cut away any surplus. This process continues until the height of the part is reached. The machine accommodates parts as large as 250 by 250 by 250 mm.

Why combine high-speed milling with a powder-bed process like this? According to Sodick, this “additive-first” approach makes it possible to achieve greater precision and density in the finished product. The laser sinters the metal to a 99.99 percent density, which has not been possible with previous versions of metal 3D printers, according to Sodick’s Masa Fukushima. Another advantage is surface finish. The hybrid’s high-speed milling capability is said to enable standard cutting to a 2-micron Ra surface finish, followed by a shift cut that brings it down to 0.47-micron Ra.

Interspersing milling operations with additive manufacturing makes it possible to finish internal structures such as conformal cooling channels, and lends itself to automated operation. Sintering, recoating and milling can all be performed unattended to complete a part in a single piece, and the combination of processes on a single machine helps to simplify IIoT integration, Sodick says. The hybrid also offers offline CAM data generation and import, and MTConnect functionality is in progress.

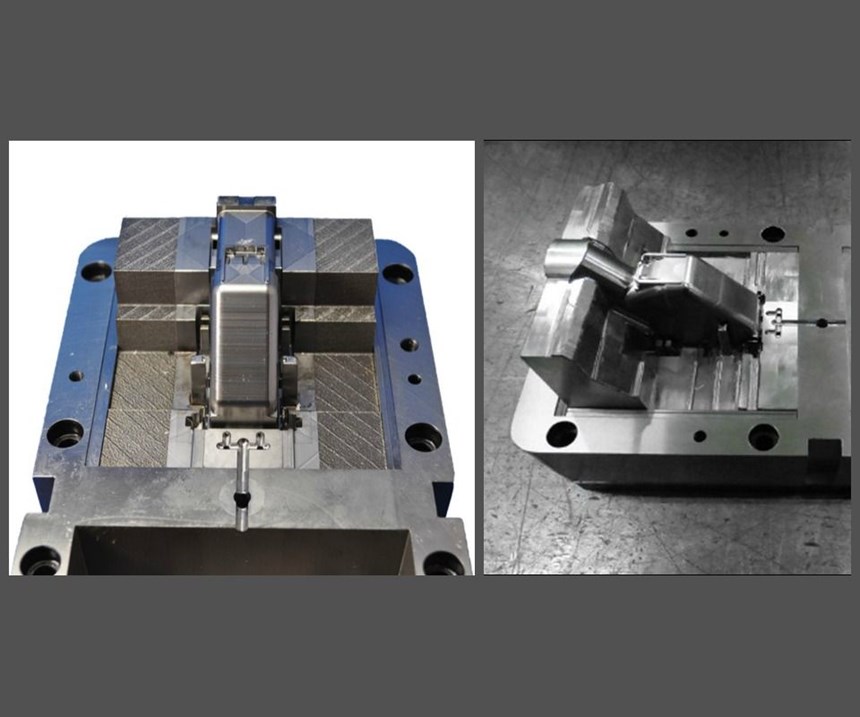

A good example of a possible application for this hybrid is a plastic injection mold. Traditionally, a mold cavity and core demand multiple setups and processes including sinker and wire EDM, grinding and milling. However, the OPM250L hybrid enables such a mold to be grown as one piece with just one setup for reduced production time. For example, the mold core pictured in Figure 4 originally consisted of 31 individual parts that required multiple machines and took more than 660 hours to produce. Using the OPM250L, the same core was created in just two parts with a 55 percent reduction in lead time and 38 percent reduction in production cost.

.jpg;width=70;height=70;mode=crop)