How to Reduce and Avoid Emissions from Polymer 3D Printing

Desktop 3D printers are immensely useful in a machine shop, but can emit volatile organic compounds (VOCs) and ultrafine particles (UFPs) that are harmful to humans. Here are some guidelines to install and operate them safely.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Fused filament fabrication (FFF) 3D printers are increasingly a common sight in machine shops and other manufacturing facilities. Read on for guidelines on how to install and operate these printers while avoiding emissions exposure.

When I began reporting on additive manufacturing (AM) just five years ago, I quickly learned about the dangers of metal 3D printing, from the combustible materials to the risks from inert gas leakages. Working with powdered metal is no joke, which is why operators are often pictured in full PPE including respirator, fire-resistant jacket and nitrile gloves. If you ask one of these folks about safety, they’ll likely point out facility features like specialized fire extinguishers, spark-resistant flooring and air quality monitoring systems. There’s a considerable and widely recognized ecosystem of training and equipment needed to run these machines.

But it wasn’t until more recently that I began to hear conversations about the safety of polymer 3D printers. I’ve been to my fair share of machine shops and other manufacturing facilities where a desktop 3D printer sits out in the open, no ventilation or enclosure in sight. The technology is so small, quiet and innocuous sitting alongside a milling or turning center that it gives off an impression of safety — an impression that may be somewhat misleading.

Desktop printers may not be running combustible powders or pose a significant fire risk, but they do bring at least one health and safety hazard: emissions. According to Aleksandr Stefaniak, industrial hygienist at the Centers for Disease Control and Prevention, there are two main emissions associated with the fused filament fabrication (FFF) style of printers commonly used to make prototypes, tooling, robot end effectors and more: volatile organic compounds (VOCs) and ultrafine particles (UFPs). VOCs and UFPs are given off when the plastic filament is melted during printing, and as they cool, VOCs can condense onto the ultrafine particles and be breathed in by nearby humans. The emissions can irritate lungs and exacerbate asthma, among other side effects.

Many factors contribute to the quantity and danger of 3D printer emissions, including the material used, the temperature at the nozzle and within the build envelope, and the size of the room where the 3D printer is located. Generally, higher printing temperatures lead to higher emissions rates. A single printer on the shopfloor in a large facility operating at lower temperatures is less of a risk than one or more 3D printers running high-temperature filaments in a small room, for example.

For organizations that want to implement FFF 3D printing, the National Institute for Occupational Safety and Health (NIOSH) provides a hierarchy of recommended controls, from most to least preferred:

- Avoid the hazard altogether. The best-case scenario is to simply avoid emission risks in the first place. This could be accomplished by purchasing an enclosed 3D printer with the appropriate exhaust and filtration systems already in place, or choosing to build with low-emission materials such as PLA. Users should also avoid “hacks” to printers like swapping nozzles to achieve a higher extrusion temperature, as higher temperatures allow greater quantities of VOCs to be released.

- Engineer the hazard out of the process. Engineered controls include adding enclosures to 3D printers that don’t have them and installing printers under a fume hood or local exhaust. Fans with carbon and/or HEPA filters can also help trap and remove VOCs and ultrafine particles from the air.

- Implement administrative controls. If the risk can’t be avoided, set up policies to limit personnel exposure to VOCs and particulate. For instance, keep printers in a closed room that staff only enter when necessary to retrieve completed parts or perform printer maintenance.

- Use personal protective equipment (PPE). Operators can wear PPE such as respirators and dust masks to avoid breathing in particulate. This is the least-preferred way of approaching the problem because it doesn’t address the source of emissions, and using PPE effectively involves additional training and fit testing. It also requires due diligence to confirm that the filters and cartridges used in PPE are the correct ones to remove the contaminants at hand.

Check out this longer conversation on 3D printer emissions with Mr. Stefaniak and NIOSH researcher Lauren Bowers for more information, and to see how the printer farm above was ultimately enclosed and ventilated.

Related Content

How to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreSpeeding Up Splines

Moving small- to medium-batch production from outsourced, dedicated hobbing operations to in-house, CNC multitasking machines helps job shops achieve quick turnarounds and flexibility in supplying splines for the heavy-vehicle industry. Inserted disc cutters make this transition possible.

Read More6 Variations That Kill Productivity

The act of qualifying CNC programs is largely related to eliminating variations, which can be a daunting task when you consider how many things can change from one time a job is run to the next.

Read MoreRead Next

Lessons About Metal Additive Manufacturing from a Hands-on Class

The metals you’re used to may not be the metals you want to 3D print. This and other lessons from the Additive Manufacturing Institute of Science and Technology (AMIST).

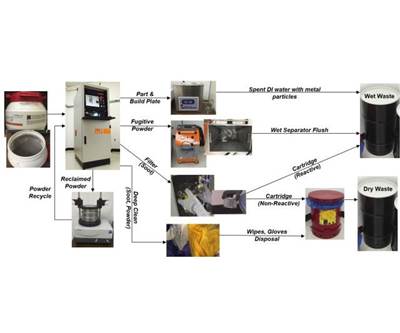

Read MoreInstalling a Metal 3D Printer Series

A five-part series documents one manufacturer’s experience and lessons learned while installing a powder-bed fusion metal 3D printer.

Read MoreWith 3D Printing, Fixture Making Goes from the Tool Room to the CAD Room

For Ira Green Inc., fixture design and iteration used to take days, even weeks at times, and at a high cost per fixture. With a 3D printer, the shop’s entire process has changed, drastically increasing efficiency and cost effectiveness.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)