How One Shop Machines Advanced Ceramics

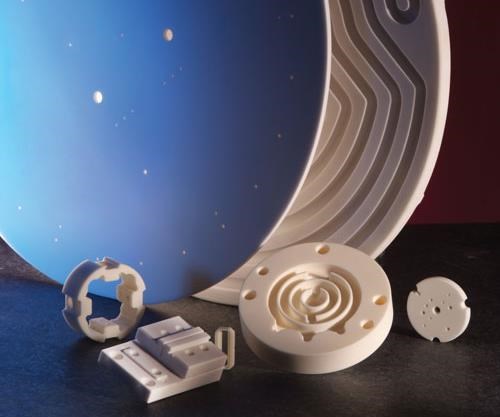

Years of trial and error combined with the appropriate machining technology allow this company to produce custom parts made of alumina, zirconia, boron nitride and other advanced ceramic materials. One example of key machining technology is a five-axis machining center used exclusively to produce the complex, tightly toleranced geometry that fire-hardened workpieces require.

Share

Takumi USA

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View MoreDemand for advanced ceramic components will increase to more than $12 billion in 2010, according to the Freedonia Group, an international business research company in Cleveland, Ohio. Uses for ceramics that are likely to grow include ballistic armor, ceramic composite automotive brakes, aerospace diesel particulate filters, joint replacement components, dental products and piezoceramic sensors. In the meantime, electrical and electronic applications such as insulators, igniters, heating elements, heat shielding components, connectors, seals and magnets will continue to be big consumers of advanced ceramics. Many of these applications will require precision, multi-axis machining as an essential part of the manufacturing process.

This bodes well for Superior Technical Ceramics in St. Albans, Vermont. Machining advanced ceramics is one of the company’s specialties. Superior machines ceramic workpieces in both the "green" (unfired) and sintered (fired) states. Sintered workpieces are much harder and denser than green ones and must be machined with diamond grinding tools. Instead of using traditional grinders, the shop often uses standard CNC milling machines and machining centers for these grinding operations. One striking example is a five-axis machining center used exclusively to produce the complex, tightly toleranced geometry that fire-hardened workpieces require. The volumetric accuracy of this machine has allowed the company to bid on jobs involving features with tolerances as small as ±0.0002 inch (0.005 mm). This machine, a Vertex 550X-5X from Mitsui Seiki (Franklin Lake, New Jersey), was installed in April 2008.

However, successful machining requires more than machines with exceptional capabilities. The shop relies on its years of experience working with ceramic material to understand and control critical variables that can affect part production. The "art" of ceramic processing combined with the "science" of high-precision machining technology have helped Superior build a reputation as a premier manufacturer in this field.

Way Beyond Porcelain Or China

Ceramic materials can be divided into two major divisions—traditional and advanced. The origins of traditional ceramics date back more than 26 centuries. Modern applications include both consumer and industrial products, including dinnerware, tile, abrasives for grinding or lapping and those fanciful figurines made by hobbyists at local community centers. Advanced ceramics have roots extending to the early 1700s, for refractories and other applications that take advantage of their inherent lubricity, strength and heat-resistant properties.

Ceramic materials can be divided into two major divisions—traditional and advanced. The origins of traditional ceramics date back more than 26 centuries. Modern applications include both consumer and industrial products, including dinnerware, tile, abrasives for grinding or lapping and those fanciful figurines made by hobbyists at local community centers. Advanced ceramics have roots extending to the early 1700s, for refractories and other applications that take advantage of their inherent lubricity, strength and heat-resistant properties.

Ceramic science and engineering grew significantly in World War II when the military’s need for high-performance materials surged. Today, advanced ceramics are found in all sorts of components, from cell phones to space vehicles. Cordierite, titania, zirconia, alumina, beryllia, steatite, silicon carbide and silicon nitride are among the most commonly used advanced ceramics at present. Generally, advanced ceramic components are produced for one or several of the following attributes: dielectric strength; electrical isolation; high-temperature tolerance; corrosion and wear resistance; thermal shock resistance; liquids and gas impermeability; and low thermal expansion rates.

The history of Superior Technical Ceramics is venerable in its own right. The company began in 1898 as an import house for making gas lighting fixtures. During World War I, it began producing radio tube insulators. The company’s products supported World War II, and then in the 1970s and ’80s, it expanded into more advanced ceramics such as alumina for jet engine igniters. Today’s business comprises a host of custom ceramic parts made from alumina, zirconia, zirconia-toughened alumina, steatite, mullite, cordierite, grade-A lava, Macor and boron nitride. Superior has in-house capabilities to design, engineer, tool and manufacture these advanced ceramics in quantities ranging from one prototype part to large production runs. The company also sells a line of standard ceramic blanks such as tubes, rods, plates, bolts, nuts and washers. About 100 employees fulfill most orders completely within the 135,000-square-foot building at the Vermont location, although two sister companies assist with such secondary operations such as plating and adding other types of layers to parts.

Until recently, the company was led by the late Ted Church, whose great uncle founded the firm. Mr. Church often quipped that although the company was more than a century old, "It takes almost that long to know what you are doing in this field."

As with most such remarks, a kernel of truth lies beneath it. There is a learning curve with advanced ceramics, both in the creation of the materials themselves and in subsequently making precision parts out of them. Superior has earned a remarkable and reliable reputation over the years, particularly in the area of grinding brittle, post-fired advanced ceramic components.

Soft Or Hard, But Never Easy

All advanced ceramics start out as granular powder made up of a base material, such as alumina or zirconia, that is mixed with other stabilizers and binders to give each batch its own distinctive characteristics. The material is first formed using one of several methods—isostatic pressing, extrusion, injection molding or mechanical pressing. Isostatic pressing involves applying pressure of equal proportion from all directions. This process is commonly used to form complex ID configurations by compressing powder around a pin.

All advanced ceramics start out as granular powder made up of a base material, such as alumina or zirconia, that is mixed with other stabilizers and binders to give each batch its own distinctive characteristics. The material is first formed using one of several methods—isostatic pressing, extrusion, injection molding or mechanical pressing. Isostatic pressing involves applying pressure of equal proportion from all directions. This process is commonly used to form complex ID configurations by compressing powder around a pin.

Extrusion involves forcing material through a die in the same manner used to create non-ceramic extruded materials. This is a standard process for tubes, rods and barstock materials. Injection molding of ceramics is also similar to the process used for other materials. Injection molding is used mainly for very intricate or high-volume components. Injection mold tooling is expensive, but amortizing the total cost across high volumes can lower per-part cost. Mechanical pressing uses steel or carbide tooling that creates a net or near-net shape. The tool is filled with powder, and uniaxial force is applied to compress the powder.

Superior’s green machining department has CNC mills, CNC lathes, cut-off saws, surface grinders and rotary grinders. However, the extremely abrasive nature of ceramics requires the use of polycrystalline boron nitride (PCBN) and polycrystalline diamond (PCD) tooling as well as abrasive wheels.

To make a ceramic hard and dense, it must be sintered at high temperatures for prolonged periods in gas or electric kilns. Typical firing temperatures for alumina, mullite and zirconia reach 2,850º F to 3,100º F. Firing cycles can range from 12 to 120 hours depending on the kiln type and product. Ceramics shrink about 20 percent during the sintering process. Non-uniform shrinkage as a result of standard forming and machining processes can cause deformation of the ceramic workpiece.

Here’s where that kernel of truth resides: it takes many years of experience and knowledge in specific firing and machining methods to achieve desired results.

"That’s the art of working in advanced ceramics," says Al Mayer, engineering manager. "We have to know the material characteristics well enough to be able to predict accurately how much it is going to shrink, and then repeat it reliably after the initial test fire to make a production run. There’s variation in material, there’s variation in the forming, there’s variation in the green machining and there’s variation in the firing. There are at least four major variables, with countless nuances within each."

Gentle handling of advanced ceramic parts is practiced throughout the shop. When the parts are green, they are soft and can break like chalk. Once fired, they are extremely brittle. They chip and mark easily. The firing process stresses the material because the outer surface acquires a "skin." That skin reacts differently than the inner material. During grinding, the grain on the inside of a post-fired part is exposed, and the part can warp out of tolerance once it’s taken off the

fixture.

"We made a conscious effort to develop a deep specialty in diamond grinding because that’s the area where we could provide a value-added service to our customers," Mr. Mayer says.

Art Meets Machining Science

"By virtue of the tooling we use, we transform all of our machines into grinders, even if they are not traditional grinders per se," Mr. Mayer says. Lately, business demand has prompted the shop to expand its capability in a different direction altogether. For Superior, that capability has been supplied by the Vertex machining center. It is equipped with diamond grinding tools to process the complex and precise work on which the company was being asked to quote. According to Mr. Mayer, the shop needed to specify a machine that could machine accurately within "tenths" and do so consistently. "To accomplish that, you need a machine with even better positioning and volumetric accuracies than what your part tolerances are. We follow an ‘eight times’ rule—your machine should have eight times the resolution of the closest part tolerance, like a coordinate measuring machine," he explains. Superior, he says, turned to Mitsui because it is one of the few builders whose machines can achieve positioning accuracy within 12 microns anywhere in the cube-shaped machining zone. The company also felt that this builder’s applications and service engineers would be very helpful.

"By virtue of the tooling we use, we transform all of our machines into grinders, even if they are not traditional grinders per se," Mr. Mayer says. Lately, business demand has prompted the shop to expand its capability in a different direction altogether. For Superior, that capability has been supplied by the Vertex machining center. It is equipped with diamond grinding tools to process the complex and precise work on which the company was being asked to quote. According to Mr. Mayer, the shop needed to specify a machine that could machine accurately within "tenths" and do so consistently. "To accomplish that, you need a machine with even better positioning and volumetric accuracies than what your part tolerances are. We follow an ‘eight times’ rule—your machine should have eight times the resolution of the closest part tolerance, like a coordinate measuring machine," he explains. Superior, he says, turned to Mitsui because it is one of the few builders whose machines can achieve positioning accuracy within 12 microns anywhere in the cube-shaped machining zone. The company also felt that this builder’s applications and service engineers would be very helpful.

In machine building, volumetric accuracy is achieved by reducing errors in pitch, yaw and roll. This can be accomplished by hand scraping the way surfaces. The accuracy of hand scraping is checked with an autocollimator. By looking through this telescope-like device, the scraping technician can detect misalignment and make adjustments. Also, how and where a machine is assembled affect accuracy. Mitsui Seiki’s factory in Japan, for example, has a tightly temperature- and humidity-controlled environment. To isolate the assembly area from vibrations, it sits on a thick concrete base.

"Our five-axis machine has a tilting, rotating trunnion for the A and C axes. By design, those rotary and tilting axes have dual side support that bolsters rigidity," Mr. Mayer says. For Superior, this feature has proven to be an advantage over designs that support the rotary axis on one side or very small areas on both sides. Also, the linear axes move the spindle only, whereas the

rotary axes move the workpiece, an arrangement that enhances control of machine dynamics,

Mr. Mayer says.

Recently, the company ran a test piece on the five-axis machine for an order it hoped to win. This proprietary aviation industry part requires 36 cone-shaped bolt holes at compound angles, all with a ±0.0002-inch (0.005-mm) tolerance on location. Tolerance on diameters is ±0.0005 inch (0.012 mm) and on depths the tolerance is ±0.0003 inch (0.007 mm). Further complicating the job, the workpiece must be turned over so the holes can be counterbored. The machine’s C axis spins like a lathe to cut those cone shapes on the backside of the part—an operation that would

conventionally be done on an ID/OD grinder,

Mr. Mayer says.

"Many of the holes have slightly different

geometries, and the precision of the locations is off the charts. We could never achieve the perpendicularities or the parallelisms we need without the trunnion and the jig grinder accuracy on a five-axis machine," Mr. Mayer says.

Tooling And Other Considerations

Generally, precise components with extremely tight tolerances and those that call for certain surface finishes require post-fired machining. At this stage, ceramics can be machined only with specialized superabrasive diamond tooling. Mr. Mayer explains that tooling is "a whole other science within the science of advanced ceramic machining." As with steels, ceramics come in different grades and hardnesses. For example, alumina oxide can be cut with almost any

grade of diamond wheel, whereas zirconia requires a much finer grit (>220). Preplanning is key to ensure there are enough tools with the right selection of grit sizes for a project because these special tools are not always readily available.

Generally, precise components with extremely tight tolerances and those that call for certain surface finishes require post-fired machining. At this stage, ceramics can be machined only with specialized superabrasive diamond tooling. Mr. Mayer explains that tooling is "a whole other science within the science of advanced ceramic machining." As with steels, ceramics come in different grades and hardnesses. For example, alumina oxide can be cut with almost any grade of diamond wheel, whereas zirconia requires a much finer grit (>220). Preplanning is key to ensure there are enough tools with the right selection of grit sizes for a project because these special tools are not always readily available.

Like all of its post-fire milling machines, the company equipped its Vertex with diamond end mills, wheels, reamers and core drills. Mr. Mayer stresses the importance of keeping tools "short and stout" so that the process is as rigid as possible. Most tools extend 3 inches or less from the toolholder. The diamond grain on the tools is about 0.003 inch in diameter on a 220-grit soft metal matrix material. Unlike chip cutting, grinding is an abrasive process, so a wear factor with the diamond tooling must always be addressed. For this reason, the Vertex is equipped with a Blum laser probe programmed to monitor tool wear and its effect on part size. This probe signals the machine to compensate for any wear detected.

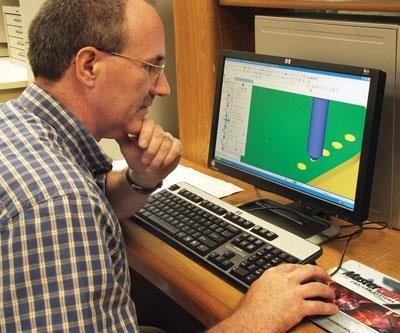

The company uses Mastercam to program the toolpaths. Superior’s Process Engineer, Tim Gleason, has a background in G-code programming and AutoCAD. He uses the CAM software’s Mill program, which he’s had to adjust for the shop’s grinding operations. "For example, we take maybe 5 microns depth of cut compared to 0.020 inch in a steel milling operation. A thousandth would be a heavy cut for us. We have to take a lot of laps and slow the feed rate down to about 40 inches per minute," he says. Certain features in the software have helped with grinding on a five-axis machining center. Mr. Gleason points to a feature that, he says, "literally asks you ‘Where is the pivot point?’ So when you are performing the dynamic rotation, the tilting and rotating axes are interpolated for you automatically."

The abrasive nature of ceramics and the abrasive tools themselves raise yet another challenge. As with most other "hard machining" operations, coolant must be used to dissipate heat and to flush away the ceramic swarf, which can damage both the machine and the production. Moreover, the loose diamond debris can scratch or mar the ceramic part. Miniscule diamond particles in the coolant are especially likely to ruin a part when a very fine finish such as 6 rms is called for, Mr. Mayer says. To address that issue, Superior brought a centralized coolant system on line about one year ago. The 5,000-gallon system uses a water-based emulsion specifically formulated for post-fired machining operations. It allows the ceramic and diamond particles in the coolant to agglomerate and settle out quickly, making filtration easier and more efficient.

Another process step that post-fired ceramics may require is glazing. Glazing parts eases removal of unwanted residue. For instance, spark plugs and other insulators are glazed to reduce areas of potential arcing in high voltage environments. Essentially, the glazing process involves dipping, brushing or spraying a glass coating onto the surface of the fired ceramic. The ceramic must then be fired again at 1,500º F to 2,700º F to sinter the glazed coating.

The last step is cleaning. Most fired alumina ceramics become dirty through handling, machining or inspecting. Oils, dirt and metal marks are removed using a variety of techniques. Superior often uses ultrasonic cleaning in mildly basic solutions at elevated temperatures. Acidic cleaning compounds are occasionally used for more stubborn metallic stains. Some critical products require a "clean fire" step to burn off all surface contaminants. This is another operation that can negatively affect tight tolerances.

"That clean fire can actually change the dimension of a fired ceramic by a very small amount. It’s usually only a few ten-thousanths, but if you put parts in that are close to the tolerance limit, you’ll get a bad part," Mr. Mayer says. "So again, you must figure in that factor when machining. That’s another unique challenge to working with advanced ceramics."

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)