Grob Holds In-House Exhibition

The line of universal machining centers was highlighted, as well as the connectivity package called Grob-Net 4 Industry.

Share

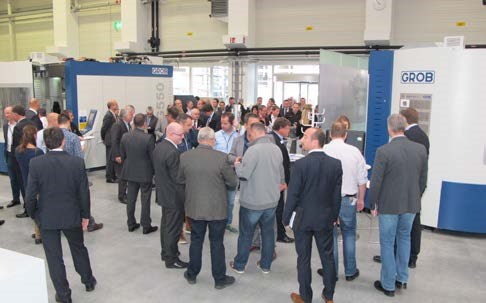

Grob’s in-house exhibition was well attended and included tours of the company’s sprawling Mindelheim, Germany, manufacturing headquarters.

Recently, I attended an open house in Mindelheim, Germany, the headquarters of machine tool builder Grob. In attendance were customers, representatives from the company’s global distribution network and suppliers from tooling, software and workholding companies. It was actually a mini trade show.

Grob is a family business that began in 1926 in Munich. It moved to its current location in Mindelheim in 1968, building a manufacturing campus that continues to grow. I was told they are the second largest builder in Europe and that the concentration of manufacturing facilities at the headquarters represents the largest concentration of machine tool building in Europe.

The company also manufactures in Bluffton, Ohio, Brazil, and China. Part of the company’s manufacturing strategy is to make these three satellite plants capable of making the same product lines as the German headquarters. They do this by pursuing vertical integration.

Highlighted at the open house was the line of universal machining centers built around the company’s G series of HMCs with multitasking capability. These machines are modular in design and can be customized with workholding, palletization, extended tool storage and myriad of other modules to customize the base model to a given application.

The other side of the company’s business involves machining systems that serve the automotive industry, in which Grob holds a significant market share.

Another highlight of the visit is called Grob-Net 4 Industry. According to Christian Grob, this connectivity package was implemented and tested in the Grob factories and is now being offered to its customers. We’re seeing this trend from other machine tool builders as Industry 4.0 and what we call the IIoT (Industrial Internet of Things) gains momentum.

It was an interesting and enlightening visit.

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)