Greenleaf Boosts OCCO's Cutter and Insert Productivity

Greenleaf Corp.’s proprietary insert, cutter and machine adjustments helped OCCO reduce crankshaft machining costs to, in some cases, a quarter of the original cost.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

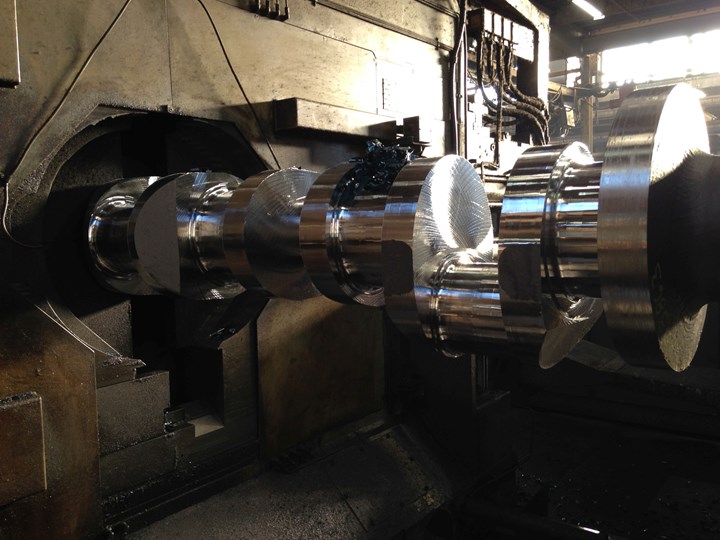

Greenleaf’s Denny Carpenter inspects the crankshaft cutter used by the Ohio Crankshaft Company.

A partnership between two companies that celebrated milestone anniversaries in 2020 — Greenleaf Corp., which celebrated its 75th anniversary, and the Ohio Crankshaft Company (OCCO), which celebrated its 100th anniversary — resulted in solutions that greatly improved OCCO’s heavy milling and crankshaft manufacturing throughput and reduced costs.

Greenleaf is a supplier of industrial cutting tools, specializing in high-performance carbide and ceramic inserts, innovative toolholding systems and custom-designed tooling solutions. OCCO produces large crankshafts, camshafts and other custom, critical components for diesel engines, pumps and reciprocating equipment.

A crankshaft cutter segment up close. The segmented design allowed for more insert pockets, resulting in faster feed rates.

In one particular application, OCCO was machining locomotive and tugboat crankshafts from steel forgings that measure between 95-165 inches long and range in weight from 2,000-6,200 pounds. Machining one shaft would take between 4-6 hours with one shaft machined per two indexes of the triangular carbide inserts. “We really felt there must be a more efficient way to do this,” says Greg Stem, OCCO’s director of engineering. “We’ve worked with Greenleaf for a long time, so we talked with them about potential solutions for this application.”

Greenleaf Corp. and OCCO worked together to improve productivity on this crankshaft machining application.

“Special tooling is one of Greenleaf’s greatest areas of expertise, so we started working closely with the engineers at OCCO,” says Denny Carpenter, sales and service engineer for Greenleaf. The cutting tool supplier altered the cutter bodies to encapsulate a segmented design, which allowed for more insert pockets. This meant the machine could apply 25% more inserts — which Greenleaf also altered from their original triangular design, in addition to boosting their total to 48 — to the parts, resulting in faster feed rates. The heat and wear resistance of Greenleaf’s GA5036, a CVD-coated carbide grade, made it well suited for high-speed milling of the forged steel. Additionally, OCCO mechanically upgraded its American GFM model FKP45 crankshaft milling machine to allow for higher cutting speeds.

These improvements reduced OCCO’s cycle time to under two hours, with four shafts machined per index of the carbide inserts.

Related Content

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

.png;maxWidth=300;quality=90)