GF Machining Solutions Opens “Center of Competence” Facility in SoCal

The company’s 106,000-square-foot facility includes machine demonstration space, customer training rooms, and resources for sales, service and applications staff for West Coast customers.

Share

Last week, I attended an open house at GF Machining Solutions’ newest “Center of Competence” in Irvine, California, part of a 106,000-square-foot Georg Fischer facility shared with sister company GF Piping Systems. Established to strengthen support for West Coast customers, many of which serve the aerospace industry, the Center includes a machine demonstration area with high-speed machining centers and wire and sinker EDM equipment as well as solutions for laser texturing and automation. It also includes customer training rooms, resources for sales, service and applications staff, and an extensive spare parts and consumables warehouse.

Here are a few shots I took while touring the facility:

This Form 30 features an ATC design whereby the 26-position tool carousel wraps around the machine column unlike a conventional ATC that would consume additional floor space.

Note the removable access panel on the left side of the System 3R Workpartner automated pallet system serving a Form 200 SP wire EDM unit. This enables the easy addition of another EDM unit to share the automated pallet system.

The company suggests that the precursor to automation is establishing a common part reference plane, which is possible using workpiece palletizing systems such as those offered by System 3R.

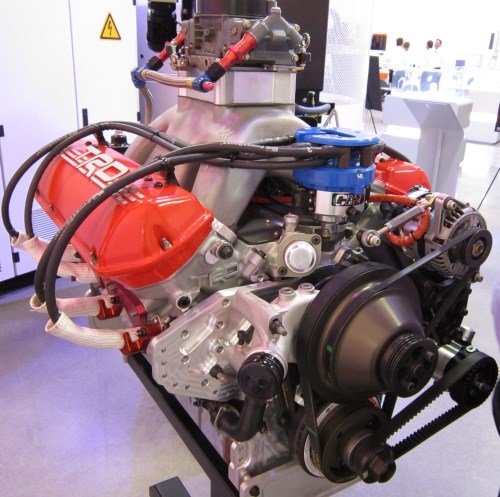

Toyota Racing Development in Southern California now uses five-axis machining equipment from GF Machining Solutions to enable faster, more accurate milling of cylinder head ports.

.jpg;maxWidth=300;quality=90)