Get the Handbook on MQL

A free handbook from Unist explains the benefits of minimum quantity lubrication and offers advice for those interested in moving away from conventional flood coolants.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

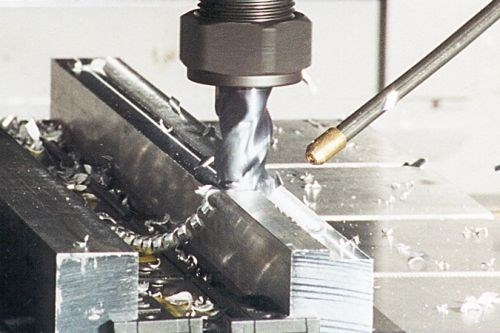

Minimum quantity lubrication (MQL) is used more in Europe than here in the States due to stricter environmental regulations across the pond. However, MQL has a proven track record in working just as well as, or better than, traditional flood coolants for certain applications. Plus, shops don’t have to deal with negative consequences like health hazards, disposal costs and pricey circulation equipment. If you’re interested in learning more about MQL, consider signing up to receive the “MQL Handbook” offered by Unist, the Grand Rapids, Michigan manufacturer of MQL systems for metalworking applications.

The handbook explains how MQL differs from conventional coolant methods, how it works, what equipment is needed, how to develop an MQL process and what fluids work best for it. Sign up to receive the handbook here.

Related Content

-

Master Fluid Solutions Semisynthetic Coolant Inhibits Corrosion

Trim MicroSol 685XT is designed to provide enhanced corrosion inhibition on all ferrous and nonferrous metals.

-

Henkel Redefines Industrial Machining and Grinding with Sustainable Metalworking Innovation

With innovative formulation and bio-resistant properties, Henkel’s new semi-synthetic lubricant emerges as a pioneering solution in the machining industry.

-

Considerations for Machining Coolant Care

Coolant care can be simply managed if you know where to pay attention and which hazards to look out for.