From Shop to Shop Management Software Provider

A co-founder of a machine shop that developed its own web-based shop management software explains why the decision was made to sell the shop and go into the software business.

Share

ProCNC is a shop I’ve written about a couple of times. In “Creating A Machine Shop Franchise Template,” I describe how the shop applied basic franchising concepts to maximize efficiency in all aspects of its business. In “Committed to Kaizen,” I explain why the shop devoted 5 percent of company time to continuous improvement activities.

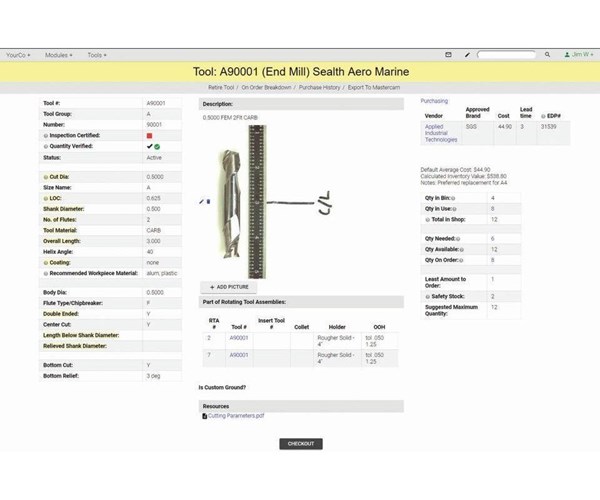

One interesting aspect of this shop is that it developed a web-based shop management system for its own internal use. But after agreeing to sell its system to a nearby shop called Sealth Aero Marine and seeing how Sealth benefitted from it, the decision was made to get out of the machine shop business and into the software business by forming Adion Systems.

Adion calls its software ProShop. Since implementing this web-based shop management system, Sealth’s annual sales have increased 125 percent while its workforce has increased by only 15 percent. Read this story to learn more about how it benefits from this web-based shop management system, which includes various individual software modules needed to track and manage jobs, work estimates, customers, scheduling, purchasing, costing and quality.

Related Content

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

.jpg;maxWidth=300;quality=90)