Four Considerations For Selecting Chucks And Arbors

For many rotational part applications, both ID and OD, a standard three-jaw chuck is sufficient. But if more specialized workholding is needed, here are some questions you must consider.

Share

Cutting rotational parts is a primary metalworking process. In this article, rotational parts are defined as parts that are symmetrical about an axis. They include round, hex, square and spline cross sections and may be gripped on an ID or OD.

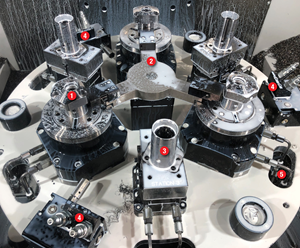

The device generally used to present these workpieces to a cutting tool is a chuck. There are many different kinds of chucks: ID, OD, three-jaw, collet, arbor, diaphragm, hydraulic membrane and others. Chucks are versatile workholding devices used throughout industry on turning centers, grinders, balancing machines, gear manufacturing equipment and machining centers.

For the lion's share of OD and ID applications, a standard three-jaw chuck will perform well. It has sufficient accuracy for many general purpose jobs. But what about those applications where a more specialized rotational workholder is needed: for accuracy, repeatability, roundness, clamping force requirements, space limitations, resistance to contamination or unusual part geometry?

To find out what considerations a shop needs to entertain for selecting such a workholding device, we talked to Jonathan Weber, director of engineering at Positrol, a Cincinnati, Ohio-based manufacturer of chucks and arbors. They've helped shops match applications with workholding solutions for a long time. Here are four areas they suggest shops consider to help make a good decision about selecting a workholding device for rotational parts: the part itself, operations, material and the machine tool.

The Part

When applications require specialized rotational part workholding, the first item of consideration, according to Mr. Weber, is the workpiece. The first workpiece consideration is whether the surface to be gripped is machined.

Gripping on an unmachined surface, such as a casting, forging or raw bar stock, is generally considered a first operation and requires a chuck or arbor that is set up to handle gripping on these surfaces. A machined grip surface indicates a second operation, and its grip requirements are different than a first operation.

The tolerance of the machined or unmachined surface of a part determines how much expansion and contraction is needed on the workholding device. Generally, a first operation part made from a casting or forging has greater variance in size than a gripping surface machined in a second operation. To allow for variance in size, more travel is needed for first operation chucks and arbors.

According to Mr. Weber, the total expansion or contraction required on a chuck or arbor is the sum of these elements: total tolerance of the gripped diameter, safety over-travel, loading clearance and, in applications using automatic loading devices, the positional accuracy of the loader. Loading clearance is the room needed, beyond part tolerance, to allow for loading the part.

Opening and closing a chuck or arbor takes time. Improvements in cycle time can be accomplished by minimizing this travel distance.

Most parts have features with related tolerances. "When planning to process a workpiece," says Mr. Weber, "it's good practice to use the workpiece datum diameter to grip on, if possible. Since all the other dimensions are measured from it, you've got a better chance at maintaining these dimensional relationships by gripping on the datum."

Another related issue is establishing the center line of the workpiece. A work-piece center line can be established when the length-to-diameter (L/D) ratio is equal to or greater than 1.5. The L/D ratio refers to the relation of the gripped surface length to gripped surface diameter.

If the workpiece has an L/D ratio of less than 1.5, its center line cannot be reliably established by gripping only a diameter. There is a tendency for the part to "cock" when loaded. A second contact point--a face perpendicular to the center line--is necessary. This face locates against a fixed workstop on the chuck or arbor and augments the gripped diameter for reliable part location.

Operations

How a shop processes its work-pieces is an important component to workholder selection. "Understanding what processes a shop is performing on its parts helps us determine the best chuck or arbor for the application," says Mr. Weber.

One fundamental question for a shop to answer is about workpiece orientation: Is it machined in a vertical or horizontal plane? In general, chip accumulation is not a huge problem for horizontal machines, but for traditional verticals, it must be considered.

It should be noted that some vertical turning center manufacturers have circumvented this chip problem by inverting the spindle. In this design, the tools are stationary on the machine base and the chuck is located on a multi-axis spindle carrier, like a vertical machining center.

But on traditional vertical turning centers, chips must be considered. Another common chip accumulation problem is on jobs that have through-hole bores. The tendency on these jobs is for chips to get pushed toward the spindle end of the part, requiring periodic removal.

One common method to deal with chip accumulation is to use a workholder with chip windows. These are cut-outs in the chuck that allow centrifugal force from the rotation of the machine spindle to expel the chips. "Usually jaw chucks don't have through-hole bore problems," says Mr. Weber.

In applications where a critical axial dimension must be held, a chuck or arbor with "pull-back action" should be considered. Although generally this action is necessary for L/D ratios of less than 1.5 (in order to locate a perpendicular face against a fixed stop), it also applies to operations where the length of the workpiece or relationships between features along the axial dimension are critical to the part tolerance.

Pull-back action is a simultaneous, two-axis motion, which grips the workpiece while pulling it in against a stop. Basically, the pull-back action ensures consistent part location from piece to piece.

Material

A chuck or arbor is a mechanical device with moving parts and close tolerances. Like any such mechanism, it is subject to contamination from chips and coolant.

Shops looking to specify a specialized workholding system need to take workpiece material into account. Several material characteristics impact successful workholding.

Chip formation is a by-product of the machining process. Depending on the machinability characteristics of the workpiece material and machining process being performed, the size of chip that's created can impact the workholder selection.

Operations that produce fine chips such as grinding or finish-turning of some materials, like cast iron and bronze, may need to employ a workholder that has a sealed mechanism. This protects the chuck or arbor's moving parts from contamination from fine chips and coolant.

"Aggressiveness of the cutting process also plays a role in the workholder specification," says Mr. Weber. "Two forces are imparted on a rotational workpiece: radial force and torsional force. Radial force is roughly perpendicular to the part center line. Torsional force is the resistance to rotation. A chuck or arbor must have sufficient gripping power to overcome these forces."

Cutting forces determine how much torque a chuck or arbor must transmit to a workpiece. In some instances, smooth gripping surfaces don't provide a sufficient coefficient of friction between the gripped surface and the chuck or arbor. Without increasing grip pressure, this friction can be increased by serrating the grip surfaces or by plating them with a material that will increase the coefficient of friction.

Machine

The next item for consideration in specifying a rotational part workhandler is the machine tool. Machine performance is a critical factor in successful application of any workholder. Matching the right chuck or arbor to the performance capability of the machine tool is key to optimum productivity.

The spindle nose is the interface between the workholder and the machine tool spindle. There are standards to define the size and bolt-hole pattern for these spindle noses.

To accommodate various size spindle noses, chuck and arbor manufacturers use adapter plates. Basically, these plates have two sets of bolt-hole patterns. One aligns the plate to the spindle nose and the second allows the workholder to be attached.

"What shops need to be careful of," says Mr. Weber, "is the amount of stand-off created by the combination of adapter plates and the chuck or arbor. Some machines have very close quarters in the cutting zone. If the workpiece is hanging out too far, interference from the tool index or from adjacent tools can be a problem."

Workzone space limitations can be expressed as maximum chuck OD, maximum chuck length (with adapter plate), minimum workpiece length and tool clearance dimension. These dimensions establish the working envelope for the chuck or arbor.

Another machine-related consideration is actuation. This involves the method employed to open and close the chuck or arbor. Generally, there are two ways to do this. One is by power cylinder, and the second is manually.

For power cylinder applications, the amount of force available is a necessary specification to help select the workholder. Adjusting the force of actuation has a direct impact on the grip force.

Two dynamics are in play for gripping a workpiece. Too much force can deform or crush a workpiece (for example, gripping on the OD of a thin-walled tube). Conversely, too little grip force has the potential to throw a workpiece out of the chuck when higher spindle speeds generate sufficient centrifugal force to loosen the grip. A shop needs to strike a balance between these two dynamics.

Centrifugal force comes into play on applications using high rotational speed--usually on turning centers. Centrifugal force on the chuck must be accommodated by using a different kind of chuck or one that is designed to counter-balance rotational forces. "Two OD chuck designs unaffected by centrifugal force are collet and hydraulic membrane chucks," says Mr. Weber.

Are Specialty Chucks For You?

Identifying the job parameters for the workpiece, operation, material and machine tool leads to the defining characteristics of the workholder that will do the best job at the least cost. That's the object of the exercise.

If you're up against a rotational part application calling for high accuracy tolerances, contamination protection, tight roundness specifications, space limitations or if it poses special clamping problems, then a specialized chuck or arbor is worth considering.

Going through this checklist of considerations may save your shop time and money searching for the right chuck or arbor. These are questions that most workholder manufacturers will ask.

Related Content

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)