Forget The Cap Screws - The Advantages Of A Dovetail Vise Jaw

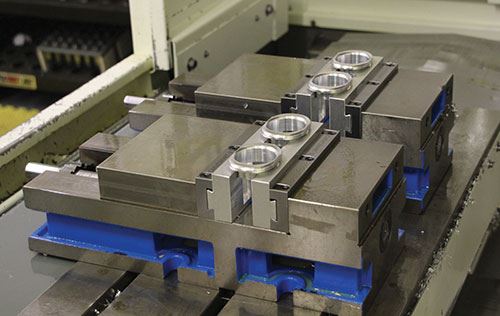

This dovetail vise uses a master jaw for quick and easy change over.

Share

The dovetail interface has been used in numerous applications that require mating components to accurately join together. Bellatex Industries, Prior Lake, Minn., has applied this concept to vise jaws, developing its Carvesmart quick-change vise jaw system to speed and simplify setups for production and tool-room vises.

With conventional vises, vise jaws attach to the face of master jaws via cap screws. Instead, the Carvesmart system uses master jaws with a female dovetail profile that accept vise jaws with a male dovetail profile. With this system, the jaws can be front-loaded or slid into the side of the master jaws, and are secured via clamping elements accessible at the top of the master jaws that provide downward pressure to keep the jaws in place.

The video above demonstrates the front- and side-loading jaw change-over processes. To remove existing jaws, an operator uses a T-wrench to loosen (not remove) three channeled clamping elements in the top of each master jaw. Because the clamping elements are located at the top of the master jaws, it is not necessary to open the vise as might be required to access cap screws in a conventional vise configuration. The operator then removes the jaws from the front of the master jaws or slides them out of the side, reversing the process to install new jaws.

The company offers dovetailed aluminum soft-jaw extrusions that shops can saw to whatever length an application requires, and says this can be half the price of a commercially made jaw or one a shop would make in-house. It says this lower cost means jaws can now be perishable/recyclable items. Shops will no longer need to store jaws when a job is complete and then take time to find, assemble, indicate and offset the machine control if the job returns. Instead, they can simply install fresh jaw blanks and cut the female workpiece form prior to a new production run. Because the Carvesmart system uses no traditional cap screws, the jaws offer a larger machinable clamping area so bigger parts can be held more deeply within the jaws, and therefore more securely in the vise.

Dovetailed jaw blanks are available in a few different sizes. Extruded aluminum jaw blanks are available in widths of 0.75 by 2, 1 by 2.25 and 2 by 3 inches, and lengths of 6, 31 and 94 inches. In addition, 6-inch-long hardened jaws are available as are 6-inch- and 31-inch-long 1018 steel jaws and knife-edge jaws.

The company’s aluminum 20000 master jaw set is machined flat and perpendicular to ±0.002 inch, is hard-coat anodized, and uses pressed, stainless steel clamp screw inserts. This set is well-suited for carved jaw production and knife-edged jaw workholding. The 10000 steel set is ground flat and perpendicular to ±0.0002 inch and is well-suited for tool-room work using hard jaws or working above the top of the vise.

Related Content

-

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

.jpg;maxWidth=300;quality=90)