For Velo3D CEO, the Future of Metal AM Is Large Producers

The growing demand for metal part production via additive manufacturing will be met by producers that start small and massively scale, says Velo3D’s Benny Buller. Thus, AM will follow a different path from other part-making technologies.

Share

This article originally appeared on our sister site, Additive Manufacturing. Check out additivemanufacturing.media for more AM content.

Velo3D CEO and founder Benny Buller says his company is discovering the different contract manufacturing landscape that will result as additive manufacturing (AM) accounts for more of part production, along with the different role that manufacturing equipment suppliers will play as AM comes into its own. He says he is adapting his vision for his company and its customers as this picture becomes clearer. In a recent conversation, he shared his thoughts about the future of manufacturing and the way ahead for AM within that future. The scalability of additive is an important factor that will influence AM’s trajectory, says Buller.

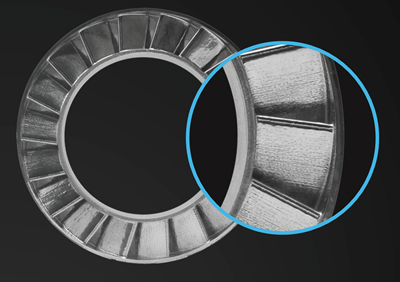

AM machines in use at contract manufacturer Knust-Godwin. Being able to add metal AM machines faster than any corresponding need to add people will allow companies offering this capability to scale up toward greater efficiency. Photo: Velo3D.

Start with this: AM is inherently more automated than other part-production approaches, in that laser powder bed fusion (Velo3D’s focus) produces a complex component in one unattended build that otherwise would have to be made through multi-step assembly. Aiding this, Velo3D points to two strengths of its system. One, the company’s system is able to produce these complex 3D printed parts with minimal or no support structures. This removes design constraints, but in terms of scaling production, the freedom from supports is relevant for the way it advances productivity per build. Two, the company’s systems operates off a printing instruction file specification allowing all the company's machines to produce a given part file to the same outcome. All this suggests how manufacturing businesses focused on additive are inherently scalable: Production capacity can increase without labor having to increase proportionally.

“Nine out of ten companies coming to us do not want machines, they want parts,” says Velo3D CEO Benny Buller. Responding to this has led him to adapt his sense of the role his company will play. Photo: Velo3D.

That is one clue to how AM will be different relative to established processes. Here is another: “We have seen that nine out of ten potential customers coming to us do not want machines. They want parts,” Buller says. Velo3D’s business is the machines; its customers make parts. But then, among those customers, he says, “In the early days, we saw utilization rates were often around 20%.” These are two different problems, but the solution to one would be the solution to the other. That is, while many manufacturers see valid and valuable metal AM applications, they are not ready to operate a laser powder bed fusion system, whereas the companies that do operate them are looking for opportunities.

Buller says his own company’s role in the manufacturing ecosystem therefore has had to evolve. As an AM technology supplier, Velo3D is a natural magnet to companies seeking to benefit from AM. In the past, if a company only wanted parts and did not want a machine, then seemingly Velo3D had little role to play. His realization now is this: The machine supplier has an active and valuable role to play. Velo3D can consult with these companies in need of parts, help them develop their designs, then connect the company to one of the users of its AM system. And this might remain the role the manufacturing technology OEM plays in additive — very different from the role of a machine builder in other types of manufacturing.

Meanwhile, the job ofthe contract manufacturers providing AM is to grow, Buller says. Velo3D attracting opportunities it can send to these manufacturers will help this along. The efficiencies that can come from additive manufacturers scaling up their capacity, so that a few employees oversee a lot of metal AM machines, are so great that Buller says just a few big providers per region might ultimately comprise the way AM production is delivered. Forget the picture of a large number of small, independent shops. Imagineinstead large facilities, each with scores or hundreds of machines and each serving the AM needs of a large geographic area. Again, the resulting picture is different from the way much of contract manufacturing is organized now, but it’s not unprecedented. Semiconductor manufacturing followed a similar path,as did, say, casting for the aerospace sector.

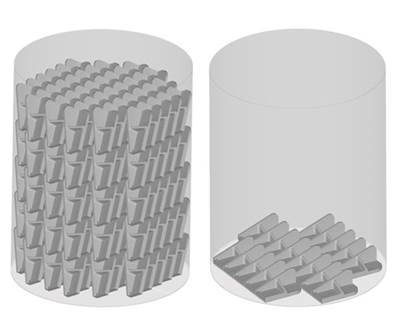

As for the opportunities these companies will find ... Buller points to fluid flow and heat transfer components covering oil and gas, processing, aerospace, and power generation: “any part in which there is energy exchange involving a fluid.”

How many AM producers? Serving how great an area? For metal AM via laser powder bed fusion, Buller says, “I estimate somewhere from five to 30 large contact manufacturers will be enough to serve the needs of each political region.” “Political region” here refers to any geographically and economically connected bloc of countries. Even for a bloc as big in its manufacturing demand as the EU, 30 or fewer very large laser powder bed fusion providers might well offer the best way to serve this need, Buller says. This is the vision he is leading his company to help realize. In part, this means Velo3D evaluates potential customers now in terms of the perceived willingness and capability of these organizations to, in Buller’s words, “massively grow.”

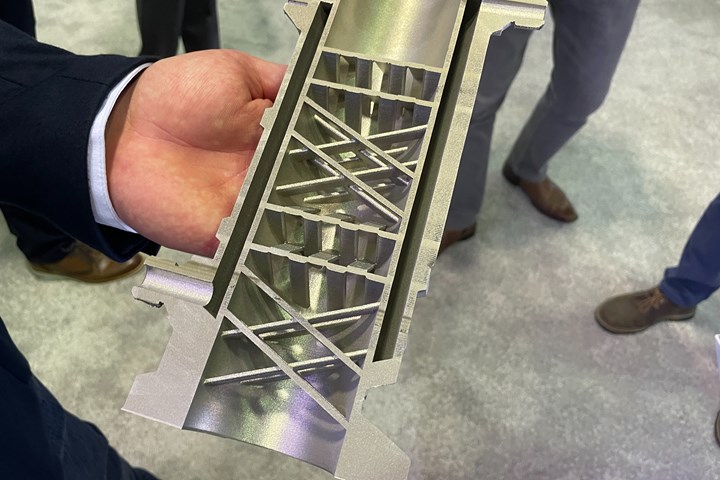

Cutaway of a static mixer made in a single piece through laser powder bed fusion. Parts involving fluid transport or energy applied to a fluid represent an important, broad category of opportunity for AM. For more on this part, see our recent Rapid+TCT episode of The Cool Parts Show.

As for the opportunities these companies will find, that too is aided by advancing sophistication in metal AM, including changes in the use of support structures. Faster, more repeatable printing of designs less restricted by supports expands the range of components for which AM is an attractive solution. Buller points in particular to fluid flow and heat transfer components — a broad category of industrial components covering oil and gas, processing, aerospace, and power generation: “any part in which there is energy exchange involving a fluid.”

In aircraft, for example, he notes that much of the value and engineering complexity is in parts fitting this description rather than structural parts. Today, components such as these are typically produced through a combination of casting, machining and assembly, and even this approach demands compromises in the internal geometry determining that part’s functionality. 3D printing itself falls short of being able to optimize the design if supports are needed inside the component to print the internal features that must orient as overhanging surfaces during the build. But in the future, Buller says AM more free of support will make it commonplace for these complex components to be designed for their optimum performance, then mass-produced quickly and with relatively little human effort within facilities employing metal AM at large scale.

Related Content

6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreRead Next

8 Cool Parts From RAPID+TCT 2021: The Cool Parts Show #32

North America’s largest AM trade show resumed! Here are some of the coolest cool parts we found.

Read More26 Steps Vs. 9: The Metal AM Case for Mission Critical Parts

Knust Godwin introduced metal AM into its precision-machining environment nearly eight years ago. Now the company is using the capability to break through into new applications and give 3D printed mission-critical parts a renewed business case.

Read MoreSupport Structures Hold Down Productivity, Says Velo3D

A build example involving an aircraft bracket illustrates the production rate increase resulting from more parts per build plus the elimination of support removal. A new system for quality monitoring aids production as well.

Read More