Flexible Fixturing Improves Cylinder Component Production

Advanced Machine and Engineering (AME) provides modular tombstone fixtures to run 56 different block sizes for Rockford, Illinois-area cylinder component manufacturer.

Share

Producing an ever-increasing variety of product sizes, styles and materials requires a flexible workholding system that can be set up quickly. By investing in modular workholding devices from Rockford, Ill.-based Advanced Machine and Engineering (AME), TRD Manufacturing increased cylinder component production while providing fast turnaround on deliveries.

TRD (Machesney Park, Ill.) gained its high-precision manufacturing expertise as a contract machining company specializing in close-tolerance lathe and mill work in the 1980s. It used this skillset to develop a line of National Fluid Power Association pneumatic and low-pressure hydraulic tie-rod-style cylinders. In 1998, the company became a division of actuation-device manufacturer Bimba, and has continued to produce cylinders and related products for customers in the fluid power industry. TRD serves the MRO marketplace, and its products are regularly specified as OEM components. The company’s cylinders are made to order, and all product lines are available with a wide variety of options and modifications.

To meet the demand for products in its ever-expanding product line, complicated by just-in-time delivery schedules, TRD required fixturing that could hold 56 workpiece block sizes while running different parts on each side. The blocks also needed the flexibility to run multiple pallet loads of the same part in high production.

TRD turned to AME, a local fixturing builder and supplier of various machine tool components. The company’s in-house manufacturing capabilities impressed Tom Jensen, TRD’s manufacturing manager, who says the company’s location just across town made it easy to work through the preliminary considerations, quoting and final product delivery.

“After a few discussions and visits to each other’s plants, we knew TRD would benefit most from our Triag line of modular workholding devices,” says Alvin Goellner, head of AME’s workholding group.

To manufacture cylinder components, TRD uses an Enshu GE480H horizontal machining center (HMC) that features a 30- by 30- by 30-inch travel and a 180-position toolchanger (expandable to 240 positions). Workpieces are mounted and handled on a Fastems 10-station pallet changer. The 56 different block sizes TRD currently uses range from 1 by 2 by 2 inches to 3 by 9.5 by 14 inches and weigh as much as 114 pounds. The more than 450 final part varieties produced on the Enshu are made from 1018 steel and 303 stainless. Lot sizes vary from one-offs to 500 pieces, but they generally average between 25 and 50. The machining center is set up to run two shifts per day, with the exception of running 24/7 during peak demand periods.

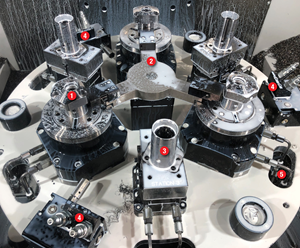

To accommodate a project of this size, TRD incorporated ten custom modular tombstone-style fixtures from Triag, a European workholding component supplier that has partnered with AME. Previously, the Enshu machining cell used fixturing that was fixed based on block size, but as Mr. Jensen notes, AME’s fixtures use a vise system that quickly adjusts to any size with repeatability—a key factor that enables all of the shop’s work shifts to be taught the process in advance.

The Triag tombstone-style fixtures keep downtime to a minimum, which is essential because the HMC with pallet changer is very costly to run, Mr. Goellner says. With the one-size-fits-all solution, the company can achieve quick setup.

“We normally have the fixtures set for specific part sizes, but this AME solution now enables us to run any size part on any pallet very quickly for high-volume jobs,” Mr. Jensen says.

As an added benefit, Mr. Jensen says the shop experienced very short startup time, as the flexibility of the tombstone design and the fixturing mechanisms were relatively easy for the operators to learn.

According to Kerry Reinhardt, TRD’s VP of operations, the overall experience was excellent. During initial discussions, AME laid out a concept and provided drawings for each fixture, which TRD then reviewed and approved based on its current production schedules and anticipated workloads going forward. Manufacturing, assembly and testing of the Triag tombstone fixtures were all done at AME so there was little delay in processing the project and accommodating design changes.

Mr. Reinhardt estimates that production on the Enshu HMC has improved by more than 40 percent after several months in operation.

Related Content

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreUsing Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

Read MoreMachining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More