Five Sides And One Zero: Shopfloor Programming For Five-Side Parts

A five-side machining program can be thought of as five different three-axis programs stitched together. Does that mean the task of programming a five-side job has to be five times as difficult, or five times as time-consuming?

Share

A five-side machining program can be thought of as five different three-axis programs stitched together. Does that mean the task of programming a five-side job has to be five times as difficult, or five times as time-consuming?

In many shops, this level of difficulty does seem to characterize five-side work. The typical user realizes five-side machining by pivoting the work (not the tool) through the use of a tilting rotary table that indexes in two axes. One consequence of reorienting the work is that any feature of the work that might have defined the program’s zero point gets reoriented as well. As a result, the five-side part generally must have five different programs with five different zero points, or else it has to be programmed offline using a CAM system that can track the positional changes. Either way, programming a job at the control is effectively eliminated as a practical option.

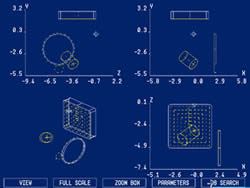

Or not. Hurco, the Indianapolis-based maker of machining centers and controls, has developed functionality that brings shopfloor programming to five-side parts. The company’s “Ultimax” CNC can take advantage of a function called “transform part zero” that lets the user define machined features at various angles and within various planes of the part using a single program zero point. The control keeps track of this point throughout the machining cycle, performing the trigonometry necessary to track the point as the part rotates from one machining angle to the next. In this way, the capability makes a five-side program easier to create. It may also expand five-side machining to cover a wider range of work.

Why Five-Side?

For the uninitiated, five-side machining refers to the ability to pivot the work or the tool in two rotary axes so that the tool can reach every surface of a part except the one that touches the table. For a cube-shaped part, five sides out of six can be machined in one cycle.

Reduced setup time is the main advantage of this approach. A part requiring holes to be drilled at seven different angles, for example, would have to be set up seven different times on a conventional machining center, but it could be set up just once on a machine capable of five-side work.

A related advantage is precision. Fewer setups mean fewer handlings of the part, and therefore fewer opportunities for error.

Add the Hurco zero-point capability, and the shop’s ability to realize these advantages potentially improves. For example, an added benefit of the zero-point function is that five-side programs are easier to re-use. This re-use may be difficult with a typical CNC. As the part shifts in position from setup to setup, the rotation through compound angles will cause feature locations to vary according to trigonometric effects that the control probably is not equipped to calculate. As a result, either the five-side program created in CAM software has to be revised and re-posted with every new setup of this job, or else the job has to be set up in precisely the same location on the table each time the part is run.

But with the control working out the trigonometry on its own, these restrictions go away. A change in the setup position becomes just one more value to include in the calculations. Not only can the same program be re-used without difficulty, but the program can also be moved to another control that has the same capability so that a single rotary table can be shared among multiple machines.

Another potential benefit of the zero-point function is a greater range of work for the five-side approach. Consider a part that requires milling and drilling in only one plane, with the exception of a single off-angle hole. A shop probably wouldn’t think of using a rotary table for this part, instead perhaps machining it on a three-axis machining center, followed by a drilling machine for the odd hole. In other words, two setups are needed.

Now consider that the shop can quickly generate a five-side program right at the control. With this capability, it may become practical to consolidate the two setups into one, even for a simple part such as this.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)