Fine Wire Is Just Fine

As parts get smaller and smaller, using EDM wire as small as 0.001 inch in diameter to cut these workpieces becomes an attractive option—actually, the only option.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Human beings have always been explorers. We want to learn about the moons and planets in the outer spaces of the universe. Likewise, we want to learn about the organs and life systems in the inner spaces of our bodies. To reach places too far away or too small to travel to on their own, today's explorers are developing vehicles and instruments unlike anything that has ever existed before.

These inventions are incredibly precise and often incredibly small. In concept and design, they represent the peak of imagination and intelligence. In construction, they approach the impossible. Who can manufacture the required components to tolerances defined in millionths of an inch—the splitting of a splitting of a splitting of a hair?

One of the companies that can is Maroney Company of Northridge, California, near Los Angeles. This shop is unique. Its assembly of machine tools, measurement instruments, and skilled technicians is like no other. It performs processes and procedures that few, if any, other metalworking shops can duplicate. Yet almost all of the machines and equipment in this shop are commercially available models that have not been modified or enhanced.

In short, what Maroney Company is doing today is what many other shops will want to do, maybe will have to do, in the future. A good example is this shop's use of very fine wire electrodes on a traveling wire electrical discharge machine. Electrical discharge machining (EDM) has always had a reputation for doing that which could not otherwise be done. Wire EDM has been particularly applicable to extreme situations calling for innovative, even radical, applications. EDMing with wire down to 0.001 inch in diameter is simply a continuation of this tradition—and not just a tradition for EDM but for Maroney Company, as well.

Maroney Company has been involved with precision EDM since 1968. Its first ram EDM was a Charmilles/Hauser model that combined EDM with jig borer accuracy. For some time this was the only such machine in the United States. Its first wire EDM, an Agietron Model 15/30, In 1995, the Maroney Company acquired an Agiecut 270 HSS2SFF from Agie Ltd. (Davidson, South Carolina), capable of using fine wire. Its newest EDM, an Agiecut Evolution, was also ordered factory-equipped for working with fine wire (0.004 inch diameter and smaller). It was installed in September, 1998. Several ram and wire units from Mitsubishi EDM (Wood Dale, Illinois) are also on the shop floor, as well as a small hole EDM drill from Current EDM (Mountain View, California).

Small Wire Work

About 10 percent or so of the EDM work performed at Maroney Company involves fine wire. As much as possible, jobs requiring fine wire are scheduled to coincide so that the special setup procedures involved are minimized. John Cameron, president of the company, says there is no such thing as a typical fine wire job because all of the work tends to be so diverse and exotic. Nevertheless, the sample is representative.

Figure 1 shows a gear-driven auger that is on the way to Mars on Jet Propulsion Laboratories' Deep Space 2 expedition. The auger is part of the probe that is scheduled to penetrate the Martian surface in December, 1999. Upon impact, the probe will collect soil samples for analysis of sub-surface moisture content using fine-wire EDMed instruments on board the probe. The spline gear components used to acutate the probing of Martian soil are shown in Figure 2.

This is not the first time Maroney Company has been to outer space with EDM. In 1968, Maroney Company was chosen as the sole source supplier to TRW Space and Defense for supplying all of the metering sleeves and pintle valves used on the lunar excursion module (LEM) descent engine on the successful Apollo 11 mission to the moon. In 1997, the Maroney Company landed on Mars with more than 235 machined components on board the Jet Propulsion Laboratories' Mars Pathfinder. Most of these components required special application EDM, such as the gears for the air bag retraction actuator assembly.These gears were EDMed from heat treated Vascomax C300 maraging steel. According to Mr. Cameron, the largest error anywhere in those gears was in the neighborhood of 15 millionths of an inch. None of the gear teeth has a uniform cross section; each tooth is slightly tapered from ID to OD.

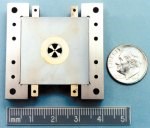

Figure 3 shows a quadrupole assembly Maroney Company fabricated for a project also sponsored by Jet Propulsion Laboratories. It is part of what is believed to be the world's smallest mass spectrometer. The center part is EDMed using 0.001 inch diameter wire through 0.750 inch thick OFHC copper. The "kissing" circle, that diameter formed by the configuration of the poles, is 0.016 inch.

Although fine wire applications usually involve lot sizes of one, two, or three pieces, "volume production" work is not unknown at Maroney. A 100-piece order for a critical component used in deep-hole oil drilling sensors is an example. Each piece consisted of a short section of tubing into which numerous side slots were made, each slot at 90 degrees from the other, leaving a web 0.0035 inch between the slots. Wire 0.001 inch in diameter was used to make the slots. These slots allow the tube to flex side to side or front to back in a precise manner to detect minute changes in the direction of an underground probing mechanism.

Fine wire EDM is also frequently used in conjunction with other types of EDM. In a recent job, a metering device that tests the displacement of insulin called for six holes 0.070 inch in diameter to be made in a stainless steel workpiece 1.875 inches high. Both size of the holes and location to each other had to be held to ±0.000050 inch. In this case, the holes were first predrilled on the small-hole EDM, then finished to size with 0.004 inch wire.

In another case, the impeller for an arterial catheter was produced by cutting a copper electrode with 0.001 inch wire, then EDMing the part on a ram machine. The details on the electrode were too small to mill and required virtually no corner radii. Because the impeller was EDMed from titanium, it had to be produced on a Mitsubishi EDM, which prevented the characteristic "bluing" that usually occurs when wire EDMing this material.

What It Takes

According to Mr. Cameron, fine wire EDM takes several key ingredients: "You have to have the right kind of machine, the right kind of wire, the right programming and control software, and the right support equipment, especially measurement and inspection equipment. Finally and most important, you have to have the right kind of operator, a combination scientist and artist."

At Maroney Company, all of the fine wire work is performed on the Agie equipment and most of that on the new Evolution. This machine is designed to hold tolerances of ±3 micron (0.00012 inch) throughout its work envelope of 13.8 by 9.8 by 10.0 inches in X, Y and Z.

In concept, a wire EDM machine is rather simple. A strand of wire feeds from a supply spool to the workpiece, via a wire drive system. The wire, energized by electrical contacts, passes through the workpiece at a set velocity as required for the specific job. A stream or bath of deionized water surrounds the wire, and the electrical current in the wire is pulsed on and off, creating sparks that cross the gap between wire and workpiece. Each spark erodes a minute particle of the workpiece as sparks emanate continuously along the length of the wire. By moving the wire in relation to the workpiece, the channel eroded by the sparking action follows a path that can be highly intricate. Spent wire exiting the workpiece from below is gathered onto a take-up reel or chopped up for disposal.

Of course, in reality, a wire machine is quite complex. The movement of the wire from supply spool to disposal is governed by a system of rollers that pinch the wire and draw it downward while other rollers apply a precise amount of tension to keep it straight and taut. A set of upper and lower wire guides, one above and one below the workpiece, position the wire on its path through the workpiece.

One of the main reasons the Agiecut Evolution lends itself well to fine wire applications is that the design of its wire drive system allows it to operate reliably in an automatic mode, even when adapted for wire of this size. For example, the wire guides have V-shaped openings rather than donut-like rings for locating and positioning the wire. The V guides facilitate automatic wire threading because the action is more like notching an arrow on a bow than threading a needle. The V guides bring the accuracy of the traditional V block used by tool makers to hold cylindrical objects on the surface plate for extremely precise measurement, only on a very miniature scale.

Tensioning rollers also allow wire tension to be adjusted in very small increments. Surprisingly, fine wire requires greater tension than that required for conventional sizes, but the band of acceptable tension is small and must be held very consistently.

Likewise, circuitry in the power supply must be able to monitor conditions in the spark gap very sensitively and be coupled to a highly responsive servo system that can adjust quickly on command. The servo system on the Evolution has the mechanical capability of making adjustments down to one tenth of a micron in a fraction of a second.

The Evolution is equipped with Agie's new Agievision control unit. Although this control was developed as a new generation CNC for several other models of Agie wire and ram EDMs, certain features stand out in applications of fine wire. One is AgieSetup 3D, an on-board measuring system that automatically detects skew and/or tilt in the fixtured workpiece and adjusts the wire path to compensate. This feature speeds and simplifies setup, minimizing the need for dial indicators. More important, it minimizes inaccuracies in the cut due to deviations in workpiece location.

Because fine wire uses relatively low current levels, metal removal rates are proportionately lower. This makes for some long burn times on certain jobs. However, a control feature called Pieceinsert allows one job to be "put on pause" so to speak, while another shorter job is substituted. Later, the machine can return to the original job and resume exactly where it left off.

Usersequence is another feature that allows the operator to synchronize operations to coincide with scheduling considerations. For example, critical operations that require the attention of the operator can be arranged to occur at the beginning of the sequence, perhaps at the end of the day shift. Less demanding operations, such as long straight cuts or skimming passes, can be reserved for the unattended mode overnight.

The Right Wire

The most commonly used EDM wire is 0.010 or 0.012 inch in diameter, usually made of plain brass. Other commonly used wire sizes are 0.008 and 0.006 inch. Brass wire coated with zinc or other alloys is also popular because it allows faster cutting. Steel core wire also has advantages because it is exceptionally resistant to breakage. Wire 0.004 inch in diameter and smaller is considered fine wire. To use wire this small, most wire machines require that special wire guides be installed. Some machines cannot use wire smaller than 0.002 inch.

The 0.001 inch wire Maroney Company uses is made of a special tungsten alloy and is imported from Japan. Tungsten has much higher tensile strength than brass, so it can be pulled harder without stretching or breaking. To put wire this small into perspective, a human hair is typically 0.003 inch in diameter. Wire that is a fraction of this dimension is difficult to see with the naked eye, so it is important to have a well lit shop area.

Herein lies a very practical reason for reliable operation of automatic wire threading when fine wire is used. Not only is wire this fine so difficult to see, it is also almost impossible to feel with the fingertips. Automatic operation minimizes the need to manipulate the wire by hand, cutting down on the frustration and wasted motion the operator will experience.

Maroney Company has also worked with wire 0.0005 inch in diameter with very exciting results.

The Right Person

Maroney Company has always prided itself on having up-to-date equipment, but from the very beginning its philosophy has been to find talented machinists and technicians, then give them the best working environment and latest equipment. The company is small—it currently has 12 employees on the shop floor.

"Ultimately, it's your people that set you apart," explains Mr. Cameron. "All of the equipment we have can be found in a show room, but skill and experience don't come in a box." Mr. Cameron points to Danny Minikus, who runs the wire EDM department, as a good example of this talent and enthusiasm.

In this case, Mr. Minikus found Maroney Company, not the other way around. He had heard about the interesting and demanding work this shop was doing with wire EDM and wanted to be a part of it. Mr. Minikus had been an EDM operator for over 15 years when he joined the company.

Tapping his forehead, Mr. Minikus describes what he likes about wire EDM and fine wire cutting: "You have to think. You have to be creative. Every job is a puzzle to be solved." The most demanding challenge, he says, is often figuring out how to hold a workpiece for machining. When parts are so small a microscope is needed to inspect them, ordinary tooling systems can only go so far. Frequently, Mr. Minikus designs and constructs special fixtures to hold small parts, using the EDM process wherever possible.

Mr. Minikus is usually involved in several EDM projects at once, so it is common to find him working with several EDM units at the same time. (All Maroney employees are typically working with several machines or processes simultaneously, which makes the work more interesting and highly varied.) While one job is running on one machine, Mr. Minikus may be setting up another. However, he handles all of the work that involves fine wire himself.

Mr. Minikus also maintains the wire machines himself, making sure routine maintenance is accomplished on a timely and regular basis. He notes that small wire cutting requires particular attention to keeping the machine clean. Changing filters on the dielectric system is especially important because irregular sparking produced by debris in the wire/workpiece gap can disrupt the EDM process.

Mr. Minikus reports that wire breakage is no more likely with fine wire than with regular diameters if sound principles of operation and handling are followed. "That's the key—be as careful as you should be with any close-tolerance wire EDMing," he says. However, he does admit that fine wire is less tolerant of conditions that are not optimal.

Although working with fine wire can be frustrating, Mr. Minikus has the calm and patient demeanor of one truly engaged and absorbed by his work.

Fine Programming

Maroney Company uses Esprit/W software from DP Technology (Camarillo, California) to program its wire EDMs. This Windows-based CAM software is not only especially designed for wire EDM, but it is also tailored to support specific models of wire EDMs from the leading EDM builders. This software developer works in partnership with the EDM builders to customize its product for better integration with the builder's control software in the machine.

For example, features customized within the software include Agie-specific input screens designed to resemble the machine tool input window, including common commands and phrases, a set of Knowledge Based Machining (KBM) strategies, and feature recognition capabilities. In fact, Maroney Company worked with DP Technology to develop Esprit software routines that support multi-axis wire operations for sophisticated spline cutting on the Agiecut Evolution.

Mr. Cameron points out that a strong CAD/CAM system is especially important for shops pursuing fine wire applications. "Fine wire is involved in so many exotic, one-of-a-kind workpieces, often with complex geometries and extremely tight tolerances, that software tools make a difference. Being able to create and view workpiece geometry in multiple layers and colors lets us be more creative in our problem-solving," he says. "It helps us develop more effective wire cutting strategies through visualization as well."

Practical considerations for fine wire are important, too. The programming software must be capable of calculating wire path data in as many decimal places as necessary to avoid rounding errors and to create smooth axis moves that minimize stress on the wire. The Agiecut Evolution resolves axis position readouts to 15 places with a floating decimal; the programming software has to provide a corresponding level of precision in its NC code.

Lab And Studio

Although Maroney Company has been involved in some rather glamorous applications for the aerospace industry, Mr. Cameron believes that fine wire EDM will become more attractive to a growing number of users. He notes that consumer goods and electronics are all moving to smaller, lighter packages, for example. As the country's population ages, developments in micro surgery are likely to accelerate, too, he predicts.

On the other hand, he believes that fine wire EDM will always be a specialty for the shops that pursue it. "By its very nature, fine wire demands a special attitude and dedication," he says. "You have to have a machine shop that combines the discipline of a science lab with the flair of an art studio." For that kind of shop, Maroney Company is certainly a worthy prototype.

Click here to learn more about suppliers Current EDM Inc., GF Machining Solutions LLC, MC Machinery Systems, Inc., Roku-Roku.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=150)

.jpg;width=700;quality=80)

.jpg;width=860)

.jpg;maxWidth=300;quality=90)