Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View MoreDuring wire electrical discharge machining (EDM) operations, effective spark monitoring is essential to ensure process control, maximize wire life and prevent wire breakage. In working to improve the capabilities of its wire machines to best monitor the state of the electrical discharges between the wire and workpiece, Mitsubishi EDM ran into an unexpected problem: The electrical signals feeding back to the control were too slow for the monitoring system to make timely, necessary adjustments to on/off time and current on its new machines to maintain consistent sparks.

One design goal for those new machines was to reduce wire wear. “Previous generations of the company’s machines had stronger sparks discharged at a lower frequency, which can be hard on the wire because of the relatively high voltage required,” says Mike Bystrek, applications manager for MC Machinery, a subsidiary of Mitsubishi Corp. that sells and services Mitsubishi EDM units and other equipment. “The new machines can produce a higher number sparks per second with less intensity, which means we needed to improve our monitoring to differentiate between ‘good’ sparks and short circuits to maintain a uniform curve along the wire.” The “curve” Mr. Bystrek is referring to is the combined shape of the electrical arcs that form between the wire electrode and the workpiece. A wire produces more uniform electrical arcs when there are fewer short circuits that would increase wire wear and possibly create surface defects. To maintain uniform electrical arcs, the company needed to improve its spark-monitoring capabilities, but found that its older controls were not able to keep up with the pace of the new machines.

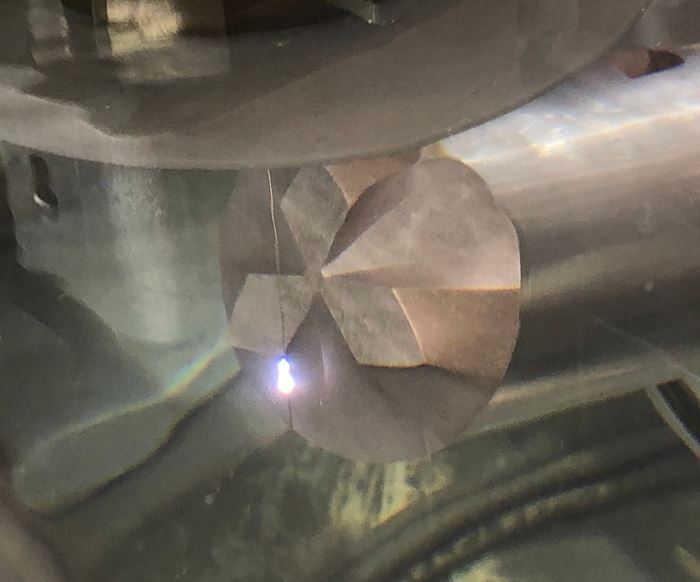

The crux of the challenge was simple: Electrical discharge machining relies on, well, electrical discharges. During operation, the spark travels from the wire electrode to the workpiece at roughly the same speed as the electrical signals moving through the wires of the monitoring system. However, the distance between the wire electrode and workpiece is far shorter than the distance between the spark and the control. This means that the control is processing out-of-date information because it receives the electrical signals well after each spark has completed, diminishing the machine’s ability to maintain uniform sparks. To solve this problem, the company developed the M800 series control, which uses fiber-optic cables to increase data processing speed for its wire EDM units.

The solution is simple, but effective. While electrical wires are limited by the speed of electricity, fiber-optic cables send data through light pulses that travel roughly 100 times faster than electrons through wires. By upgrading to “light speed,” the M800 is able to measure 128,000 sparks per second, a fourfold improvement over the company’s older controls. This enables the EDM unit to better maintain uniform spark output, reducing wear on the wire and decreasing the voltage required. Less wear on the wire translates to a slower spool and longer wire life, a cost saver for the user. According to the company, the new series of M800-equipped EDM units reduce wire usage by as much as 60 percent compared to previous models.

The M800 comes standard with the MV1200R, MV2400R, MV1200S and MV2400S series of wire EDM units. The control’s new screen design puts spark monitoring information alongside machine progress and status, emphasizing its importance. In addition to fiber-optic signal transmission, the company has added other features to the M800, which include:

- Legacy mode: This capability enables users to switch operating interfaces from the M800 to the M700 interface so that users who are familiar and comfortable with the older control can benefit from the M800’s features without having to learn a new interface.

- Onboard programming macros: This function is said to enable users to more easily program common shapes by selecting the desired shape and inputing its dimensions.

- Program suspension: Operators can pause a job when another more urgent job must be processed and pick up from that paused state once completed.

- Operational checklists: Setup personnel are said to be able to more easily set machining tasks in a specific order, and they have the option to gate tasks so that they must be completed in that exact order.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More