Establishing an Effective Hard-Turning Process

In devising its hard-turning strategy, this die/mold shop has been able to speed the production of its new deep-draw round tooling offerings by turning them instead of grinding them after heat treating.

Share

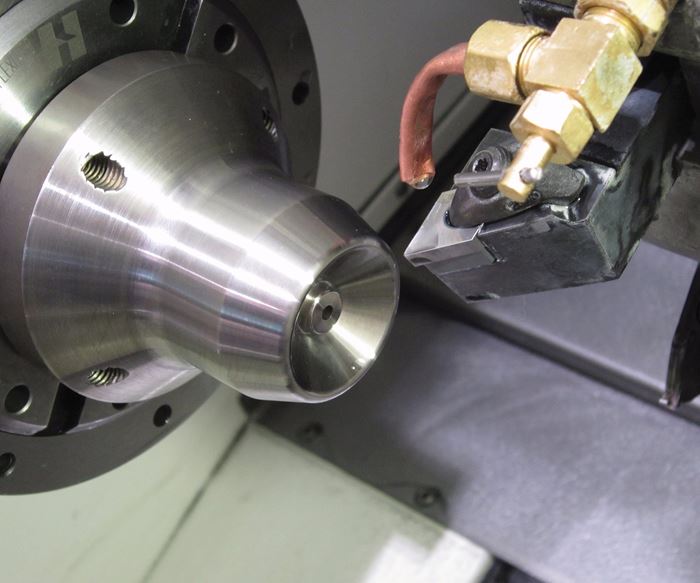

Shops that decide to expand into new markets are often spurred to add new machining equipment or adopt new machining processes to support their efforts. In True Die’s case, the strides it has taken to diversify its product offerings by manufacturing precise round tooling for deep-draw sheet-metal-forming applications has led it to develop an effective strategy for hard turning. The goal was to eliminate the need for inner diameter (ID) and outer diameter (OD) grinding of (primarily) hardened powder metal round tooling ranging to 64 HRC, enabling it to achieve higher material removal rates while matching what grinding could achieve in terms of concentricity, surface finish and dimensional accuracy. That it has since done, establishing the capability to hard-turn diameters and radii to ±0.0002-inch accuracy.

In fact, two of the Zeeland, Michigan shop’s recent machine additions are turning centers that were purchased primarily for hard turning. Mitch Stahl is True Die’s technical specialist who, along with Chris McCleary, turning coordinator, led a team of machinists in establishing the shop’s hard-turning strategy. In short, he says the shop’s approach boils down to three interconnected concepts: establishing overall process rigidity, implementing the right types of cutting tools and applying the appropriate cut data.

The key word here is interconnected. Mr. Stahl maintains that implementing only one or two of these concepts would not work; all must be appropriately addressed for effective hard turning. “It is also just as important to mind the small details when putting a process such as this in place,” he notes.

Round Tooling Opportunities

True Die, formerly Contour Tool and Engineering before it acquired that company in 2015, has expertise in designing, machining and assembling plastic injection molds and progressive die sets. It has a diverse array of machining equipment in its 10,000-square-foot facility, including CNC mills, turning centers, grinding machines, and wire and sinker EDM equipment.

Brian Brown, True Die’s president, says the deep-draw metal-forming industry represented an opportunity for the shop to diversify into a new market that complements the others it serves. “Our expertise of the application of deep-drawn stamping positioned us uniquely as a tooling supplier, enabling us to bring tangible solutions and higher performing tools to the market,” Mr. Brown says. “With well over 100 years of combined experience in the design, development and production of drawn stampings, we were well prepared with a thorough understanding of the unique requirements of that industry.”

At the time of the purchase, Contour was solely manufacturing molds and dies. Developing a strategic partnership with a deep-draw stamping company enabled and two additional customers that provided diversification and the opportunity for rapid growth, the shop to nicely round out its offerings by establishing what Mr. Brown calls its “details department,” which provides individual components for new and existing deep-draw tools and automated assembly equipment. In fact, the details work currently represents 50 percent of the shop’s sales, and the company has grown nearly 700 percent in the two years since entering the details market.

This round tooling is used in complex, progressive and deep-draw dies used to create components (typically cylindrical) from sheet metal (commonly stainless steel), primarily for automotive applications, such as components for fuel, braking and airbag systems. “We originally assumed we’d need to purchase a more capable cylindrical grinding machine to attain the tolerances and finishes the round tooling required,” Mr. Brown says. “However, given his experience with hard turning, Mr. Stahl suggested that a hard-turning process would achieve the precision the tools required and realize faster throughput than grinding because of higher material removal rates. In addition, we could also efficiently turn complex profiles in hardened materials that would be cost prohibitive to grind and possibly require form-grinding operations.”

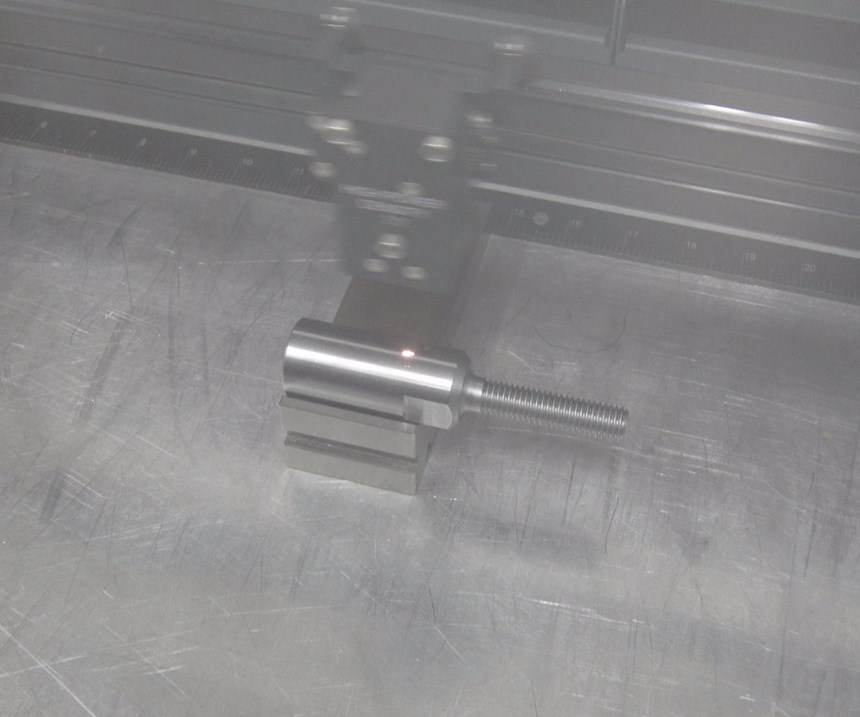

Because True Die is a job shop, its batch sizes for round tooling are low (often varying from one to six pieces), and its product mix is high. Tooling length can range to 20 inches and diameters from 0.1 to 12 inches, and many versions have high length-to-diameter ratios (L:D).

The shop primarily creates round tooling from barstock of powder metal alloys, which are made of combined particles of various metals and alloying elements. The powder metal “recipe” is compressed into barstock form that the shop first machines in its soft or “green” state prior to heat treating, which bonds the individual particles together to create the hardened component. Depending on the specific powder metal alloy, the hardness of the tooling in the green state is essentially negligible and can be effectively machined using conventional turning methods. However, after heat treating, tooling hardness can range to 64 HRC. Common powder metal steels the shop machines include CPM 3V, 9V and 10V, as well as M2 and M4.

True Die typically leaves approximately 0.010 to 0.012 inch of extra stock after turning tooling in the pre-hardened state to allow for subsequent hard-turning passes. It might leave more stock on parts that tend to warp badly after heat treating, such as those with that have a high L:D. In the case of significant warpage, the challenge is not so much achieving size tolerances, but rather tight concentricity tolerances. “It’s sometimes more difficult to get a warped part straight than it is to get it to size,” Mr. Stahl says.

Interconnecting Rigidity, Cutters and Cut Data

The two recent turning centers True Die purchased for hard turning are Mazak Quick Turn Nexus 250 II models with 12-station turrets (neither having live-tooling stations). The first of these machines was purchased in April 2016 and the second later that year in August, and they offer the rigidity the shop needed to form the foundation for its hard-turning process, Mr. Stahl says.

According to Mike Utter, the representative from machine tool distributor Addy Machinery (Grand Rapids, Michigan), who sold the machines to True Die, their MX hybrid roller guide systems are a prime contributor to their rigidity. “The rollers provide more surface contact than ball bearings, yet with less friction than slides,” he explains. “The system also effectively handles heavy load capacities, because there is less elastic deformation with rollers, and they provide a high degree of damping capability, which extends tool life. It also features an X-type design that efficiently distributes the load in four directions—radial (clockwise and counterclockwise), reverse radial and lateral—and reduces reversal errors when performing cornering motions.” In addition, the integral spindle motor used by these machines is said to provide better concentricity during heavy-load cutting than machines with belt-driven spindles.

Mr. Stahl says it is just as important to consider workholding and cutting tool rigidity during hard turning. To address the former, the shop uses collets instead of jaws to provide more surface-area contact with the barstock. “Plus, parallel clamping is easier to achieve because there is no jaw lift using collets,” Mr. Stahl says. “All mating surfaces must be clean, too, including the workpiece, collet and spindle nose.”

True Die uses the Hardinge FlexC quick-change collet system on its Nexus machines (as well as many other turning centers in the shop), which offers total indicated runout (TIR) within 0.0004 inch. The FlexC also speeds setup and change-over time when compared to conventional jaw chucks. This system features a spindle mount assembly, collet heads, and a manual wrench with trigger release used to manually install or change collet heads when the machine’s chuck is in the unclamped position.

The collet heads consist of hardened-steel segments that are joined together by a vulcanization process. Because there is no collet shank, the collet segments remain parallel to the stock. Parallel clamping is said to minimize stock “push back” and requires less drawbar force to achieve the same gripping capability as conventional collets. This system can accommodate bar diameters ranging to 3.25 inches, and a typical FlexC collet head has a gripping range of ±0.020 inch smaller and larger than its nominal size to accommodate for barstock size variation without having to change to a different-sized collet. The shop uses standard three- and six-jaw chucks for workpiece diameters larger than 3.25 inches.

To ensure cutting tool rigidity, it’s first important to position cutters at the proper tool center height, Mr. McCleary explains. “Being off-center by just 0.002 inch can cause chatter and vibration,” he says. “Plus, the smaller the workpiece diameter, the more important tool center height is.” That’s because, given the same tool distance away from workpiece center, the proportion of error increases with smaller workpiece diameters.

Tool stick-out and overhang from the toolholder should be minimized, too. Usually the determining factor is tool clearance for OD turning when using a tailstock and hole depth when boring IDs. “If hangout is resulting in vibration, the first step is to modify the speeds and feeds,” Mr. McCleary explains. “The next step would be to consider a different cutting tool insert nose radius or edge prep.”

In nearly all cases, True Die uses cubic boron nitride (CBN) cutting tools for hard turning, primarily from Sumitomo. The shop has found that CBN lasts longer than ceramics for very hard materials, is more repeatable and can be run with coolant. The tradeoff is that CBN cutters cost more than ceramic. Typically, it uses the Sumiboron BNC200 grade for continuous cuts and BNC300 grade for interrupted cutting (approximately 25 percent of the round tooling has interrupted cuts). These inserts are said to offer a good balance of fracture and wear resistance, and feature a titanium aluminum nitride (TiAlN) coating.

True Die uses diamond-shaped inserts ranging from 25 to 80 degrees (commonly featuring a negative geometry) and nose radii ranging from 0.004 to 0.031 inch. A 55-degree insert is commonly used for OD turning, with a 0.030-inch nose radius for roughing operations and a 0.015-inch nose radius for finishing work. A stronger 80-degree diamond insert is used for heavily interrupted cuts. For boring operations, the shop commonly uses an 80-degree insert with positive geometry.

Mr. McCleary says there are trade-offs when choosing between inserts featuring negative or positive geometries. “We’ve found that inserts with a negative geometry are stronger than positive-geometry inserts and also can be flipped to provide four useable edges,” he explains. However, these inserts create more cutting pressure and offer less clearance. A positive-geometry insert cuts more freely and has more clearance, but is a weaker cutting edge.

In terms of cut data, there are no firm values for every hard-turning application at True Die, as it varies depending on type of material, hardness, workpiece L:D, cutting conditions and so on. The shop might run as low as 150 sfm for heavily interrupted cuts in very hard materials to as high as 550 sfm in milder materials with a modest hardness rating.

Mr. Stahl says the typical depth of cut (DOC) the shop uses for finishing operations is 0.003 to 0.004 inch, even though cutting tool representatives have suggested that the DOC should be at least the amount of the tool’s nose radius. However, True Die has found that, in some cases, such as when the workpiece L:D is higher than 20:1, the pressure of a deeper cut would cause too much workpiece deflection and often prevent it from holding tolerances. This pressure can even impart stress into the part, causing it to warp.

By leaving 0.010 to 0.012 inch of stock to be removed after heat treating, three hard turning passes can be performed at or around the same 0.003- or 0.004-inch DOC. That way, the tool pressure is the same for each pass.

“If the previous part is turned to spec, the operator should be able to back the tool off by the total amount of stock that was just removed, such that the tool will be barely skimming the part,” Mr. Stahl explains. “Then, it’s a matter of taking the first pass to present a good surface to measure the workpiece, taking the second pass and measuring to ensure the operation is repeating, and then taking the final pass to bring the workpiece to final size.”

Using this method enables the shop to push a tool until it stops repeating. Wear is normal and expected, and can be managed as long as the insert is wearing at a repeatable amount. However, inserts must be changed or indexed to a fresh edge if the current edge isn’t repeating.

Except for interrupted cuts, the shop runs with coolant in nearly all cases. It uses coolant not to flush chips or provide lubrication, but rather to keep the part cool. “We’ll sometimes direct the coolant flow away from the inert tip, even on the opposite side of the part in some cases,” Mr. McCleary says. “The high-hardness powder metal materials generate a lot of heat during hard turning to the extent that thermal expansion from the heat can exceed our allowable tolerances. Plus, if coolant isn’t used, the operator would have to cool the workpiece after hard turning before measuring it. Using coolant enables us to measure a part instantly.” The shop doesn’t use coolant for interrupted cuts because of the possibility of thermal fracturing of the cutting edge.

Dedicate Machines to Hard Turning When Possible

One of True Die’s two Quickturn Nexus machines is reserved for hard-turning work, while the other is sometimes used when capacity is needed for conventional turning. In fact, Mr. Stahl believes it is important to dedicate a turning center to hard-turning processes if possible. “If you have the work to fill a machine’s schedule with hard-turning finishing operations, then why beat up that machine by roughing with it, too?” he asks. “Long term, you’re better off keeping one machine dedicated to hard turning, as I believe it extends the length of time that machine can effectively perform those precise operations. Plus, it enables you to keep all the appropriate turning, facing and boring tools set up in the machine, which speeds setups. That said, it’s not always practical to commit a machine to hard turning, especially in a low-volume, high-mix job shop.”

Related Content

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreWorkholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More