Enabling Small Machines to Produce Big Parts

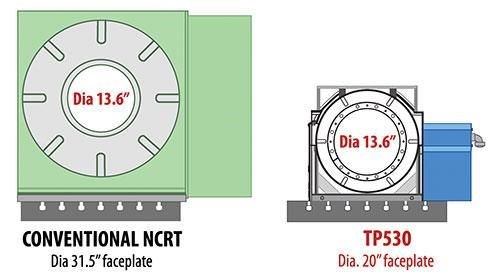

Well-suited for oilfield work, this compact rotary table has a through-hole diameter of 13.6 inches, which has previously been available only with rotary tables having a much larger face plate.

Share

This rotary table has a through-hole diameter of 13.6 inches, which has previously been available only with rotary tables having a 31.5-inch face plate. It is also 484 pounds lighter.

Kitagawa-NorthTech notes that the size of cylindrical oilfield components are getting larger. This typically would mean that shops with limited size capacity for its machines would have to purchase a larger machine not so much to accommodate the part, but the big NC rotary table. That’s why the TP530 was developed to deliver the requisite through-hole diameter in a more compact overall size than comparable rotary tables so this type of work can be performed on smaller machines. Learn more.

Related Content

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Machining Vektek Hydraulic Swing Clamp Bodies Using Royal Products Collet Fixtures

A study in repeatable and flexible workholding by one OEM for another.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

.jpg;maxWidth=300;quality=90)