Enabling Manufacturing's Future Without Limits

The Internet promises to put job shops and large manufacturers on a level playing field that extends around the world, but first they have to be able to exchange high level process models. (2002 Guide To Metalworking On The Internet)

Share

Imagine, if you will, a manufacturing environment that knows no boundaries, never sleeps and has infinite capacity. Have you just entered the Twilight Zone? Well, actually this scenario is closer to reality than you may think. And the rapidly evolving capabilities of the Internet are a key enabling technology in realizing this vision of the future.

Most manufacturers today already have some level of connectivity to the Internet, but we have barely begun to tap into the resources and capabilities that this massively distributed environment could provide us. With each connection point representing a potential data source, processing capability, or client to such services, the Internet offers a digital commercial landscape, which extends beyond traditional boundaries. As computer performance and data transmission rates continue to improve, the Internet becomes more and more transparent as a means to communicate. It is through this growing transparency of the Internet that conventional notions of time, distance and access are being redefined.

Progressive small "mom-and-pop" job shops are already beginning to get access to vast resources over the Internet, allowing them to realize capabilities and to be competitive with much larger manufacturers. Large manufacturers are using the Internet's transparency to integrate their suppliers, reinforcing the virtual corporation that they've established with them. Large or small, manufacturers' ways of doing business are being/will be dramatically altered through the Internet.

Looking into the future, especially when it involves rapidly changing technology, can be challenging at best. But many of the changes on or past the technology horizon actually have clear evolutionary roads from current technologies. Getting from today to a view of tomorrow requires mixing an understanding of the technology with a little bit of science fiction.

Beyond CAD-To-CAM

Today the Internet is commonly used to communicate design information from CAD systems to CAM systems. This exchange of information for the most part is very manually directed (in other words, the sender specifically designates who the recipient of the information is) and reflects the traditional downstream CAD-to-CAM scenario—CAD system sending, CAM system receiving. Imagine how this would change in an environment where for all practical purposes the separation between the two systems is non-existent.

For example, what if the CAD systems were able to determine the part model characteristics through a simple analysis and then were able to differentiate which suppliers were potentially capable of producing their design? Rather than setting up a serial conversation with individual suppliers, or doing a broadcast to an overly extended set of potential suppliers, the CAD system would be able to specifically target an identified group of suppliers to bid on the work. And what if the CAM systems of the supplier companies spread across the Internet were able to broadcast to interested OEMs' CAD systems the types of work that their companies were capable of doing? Better still, what if the suppliers could go beyond a static capability description and provide a real-time or near real-time projection of their workload capacity. This would allow OEMs to identify companies that not only were capable of manufacturing their designs, but also had available machine time. With the ability to match up what you want to manufacture with potential manufacturers, agent applications could be developed that would broker work between OEMs and suppliers. Even in situations where "Approved Suppliers" practices are used by OEMs, agent applications could be directed to review a narrower, pre-selected group of suppliers.

CAM systems of the future will also benefit in numerous ways as the Internet becomes more transparent. For example, most CAM vendors currently offer some level of product support over the Internet. This support can range from downloading service patches and incremental updates to full releases. But imagine what it would be like to instantly access the latest application functionality over the Internet.

Application Service Providers (ASPs) have only begun to scratch the surface of providing application functionality over the Internet. Their model of renting application time is reminiscent of time-sharing. As the Internet becomes more transparent, the overhead of accessing functionality or transferring data between client and server is no longer an issue. Batch processing functions—data is sent for processing; processed data is returned—available today to handle specialized operations such as data translation or toolpath optimization will evolve into broader capabilities such as high speed machining tool path generation or data servers capable of providing evaluations of different representations. As large volumes of data become capable of moving effortlessly between client and server or servers, the notion of the central computational platform will disperse across the Internet. Local computers could become a window onto that distributed capability, rather than having to provide localized capability. In such an environment, new capabilities can be readily incorporated and accessed. And given the timelessness of the Internet, computationally intensive work can be dynamically parceled out across servers, leveling the load and improving response times.

Integrating The CNC

CAM systems of the future will also be able to access a wide variety of manufacturing information over the Internet. Today a number of tooling suppliers offer online tooling catalogs and allow users to download digital files that describe the geometric characteristics of that tooling. CAM systems of the future will not only be able to use downloaded tooling geometry, but they will also be able to make use of vendor-approved manufacturing processes for the tooling. This information, determined by the tooling vendor's research, would provide recommended machining parameters based on different conditions, such as material type. Using this information, the manufacturer would be assured that the tooling was being used in a manner consistent with the vendor's recommendation.

The idea of using the Internet to access a wide range of tooling information can be extended even further. For example, what if a CAM system's selection of tooling over the Internet could be driven by process requirements? This would allow the CAM to identify what type of operations it was trying to perform in a particular context, and a search would be done to find specific tooling that satisfies the operation's requirements. Finding an appropriate process with corresponding tooling would be similar to finding standardized parts over the Internet today.

Last in the production pipeline, but certainly not least, the relationship between CAM systems and CNC machine tools is being radically revised through advances in technology including the Internet. Up until just recently, CNC machine tools were equivalent to metal plotters, creating objects from the stroke commands sent to them. CAM/CNC was the last frontier of integration being even less integrated than CAD/CAM. But with the introduction of PC-based, Internet-enabled controllers, this is all changing. Not only is this new breed of controller able to connect onto the manufacturer's network, but it also has some localized general purpose processing capability. This type of machine tool represents a perfect example of both a processing capability and a data source with potential greatly enhanced by Internet connectivity.

With PC-based controllers, standardized processing capability that is taken for granted throughout the rest of a manufacturer's organization is brought down to the shop floor and the machine tool. Even given the limitations of many of today's hybrid (PC hardware front-ended to conventional real-time control hardware) PC-based controllers, such as less powerful processors, less RAM, less capacity hard disk, lower resolution screens, and limited input devices, they are still capable of running applications that provide powerful, new capabilities on the shop floor. PC-based controllers, which are based on standard PC hardware, have none of these limitations. In either style, controllers are now capable of running manufacturing applications ranging from G-code editors, to visualization/validation, to shopfloor programming systems. Rather than just being plotter in metal, these CNC machine tools can be capable of optimizing G-code, making adjustment to programs based on changes in tooling or process parameters, or even expanding high level representations into tool path strokes.

But because of the Internet, these controllers are also capable of realizing new levels of integration with CAM systems. At a local level, CAM systems will be able to establish an active integration with controllers that will allow information to be fed back to the CAM system at any point while executing the program. The real-time feedback provided back to the CAM program will allow it to adaptively adjust the process to reflect current conditions on the machine tool. For example, broken tooling can be replaced. Product quality can be monitored so that the process can be modified to stay within specifications. Machine performance characteristics can be determined to establish process parameters for standardized processes. These can be stored and reapplied, ensuring a higher level of consistency.

STEP-NC Steps In

On a wider scale, the Internet creates a virtual machine shop that extends across its entire expanse. Jobs can be distributed over the Internet and run where there is capacity. Though distributed manufacturing will still need to address shipping the parts or sub-assemblies back to the OEM for assembly, manufacturers will gain access to available machine capacity. For some products or industries, locally manufactured replacement parts, which are installed in the field, may be a cost-effective approach.

The Internet is the backbone on which all of these technological advances are made. But it is only the communication mechanism. In order to realize the real potential of the Internet, a critical issue that must be resolved is the way information is represented when communicated over the Internet. Though technological advances may be bringing nodes on the Internet closer and closer, having a common representation with which to communicate between nodes is necessary to facilitate transactions. Proprietary representations could support such exchanges, but they would be limited in their adoption. Existing data formats could be used given that they have been in use for many years, but their appropriateness for the Internet is questionable.

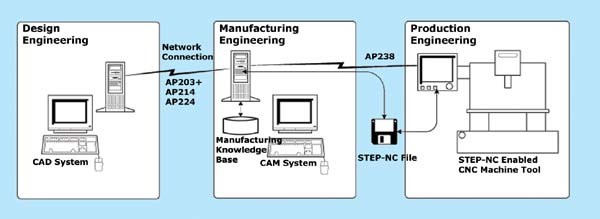

Recognizing the need for an international data standard that would support worldwide, Internet-based commerce, the International Standards Organization (ISO) initiated the STEP (STandard for The Exchange of Product model data) program to develop a data exchange format with the purpose of providing complete, unambiguous, computer-interpretable product data model schemas for a wide variety of disciplines. The initial support for mechanical design information was addressed with AP203 (AP stands for application protocol, a discipline-specific sub-section of the overall STEP standard). Today, most design systems are capable of writing and reading the geometry contained in an AP203, which covers wireframe, surface and solid entities. Though AP203 is a significant improvement over existing data exchange formats, its focus is on design geometry, not manufacturing information. ISO recognized the need for an application protocol specifically for manufacturing and started STEP-NC, AP238. The objective for STEP-NC is nothing short of providing all the information necessary for manufacturing and manufacturing decision-making.

In an Internet-enabled environment with no boundaries, an international data standard capable of addressing an industry segment's data requirements is key. STEP-NC offers the potential of being just that—an international data standard (formally sanctioned by ISO), which is targeted at the manufacturing segment. Because of the broad range of data that STEP-NC represents, it will be able to play a wide role throughout the manufacturing process.

For example, STEP-NC can be used to communicate process information as well as a full product model containing both part geometry and specifications between a CAM system and a CNC machine tool. Because STEP-NC represents a higher level of information than what G-code does, an intelligent controller will be able to do more locally than it would when using stroke-based G-code. And any changes introduced on the controller could be encoded in the STEP-NC file and sent back to the CAM system to be incorporated into a library of standardized processes.

Libraries of standardized processes could also be stored in STEP-NC format allowing manufacturers to leverage their process knowledge across multiple CAM systems, especially important in an environment when CAM systems come and go. Stored in a STEP-NC format, manufacturers will be able to protect their process knowledge, a valuable resource. Basing standardized libraries on an industry standard format, manufacturers will be able to leverage best practices not only within their own immediate organization, but also across their select suppliers.

STEP-NC will also allow OEMs to provide a complete product and process model from which suppliers will be able to produce parts. Because STEP-NC allows high-level process information as well as an explicit tool path to be stored, operational guidelines can be established between OEMs and suppliers. These determine how much latitude the suppliers have, for example, whether suppliers can generate their own tool path, or if they must use the tool path in the STEP-NC file.

The ability to encode macro process plan data (specific to a particular machine tool setting) as well as micro process plan data (explicit tool path) allows STEP-NC to bridge between macro and micro processing planning systems. For the first time, a common representation storing the results of each phase of manufacturing engineering is available. And because the STEP-NC file contains all this information, it is available throughout the entire production process, right up to machining the part on a machine tool.

But possibly the single-most important aspect of STEP-NC has to do with exchanging data from CAD to CAM. A STEP-NC file has the ability to encode a complete product data model—both product geometry and specification (non-nominal data, such as geometric tolerances). The lack of a complete product data model in a computer-interpretable, digital format has been what has kept CAM applications from realizing their next level of automation. With this data encoded in a STEP-NC file, CAM applications will have the information they need to augment manufacturing decision-making. At this point, the manufacturing engineer's primary role will shift from data fusion to decision making.

Adapting To A New Reality

Manufacturing of the future will not be defined only by being based on the Internet, but also by the information and services accessed over the Internet. As the Internet enables access to more information sources and services, traditional product development scenarios used today are being radically changed. New data formats, such as STEP-NC, will play a key role in communicating manufacturing data over the Internet. As in the past, a manufacturer's ability to benefit from this change will be determined by its ability to adopt and apply these new tools and capabilities.

About the author: John Callen is vice president-marketing at Gibbs and Associates. He can be reached at (805) 523-0004 or by e-mail at john@gibbscam.com.

Related Content

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

Read MoreContinuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreTips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreRead Next

What Does It Take To Internet-Enable Machine Tools?

It takes data—complete machine and process data from a machine tool that is easily linked to a factory network and easily exported.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More