Easing the Entry into Additive Manufacturing

With funding from America Makes, Optomec and MachMotion worked together to develop a retrofit additive manufacturing system for machining centers.

Share

When a manufacturer begins to contemplate additive manufacturing, the first obstacle the company often confronts is the cost. Machines for making production metal parts through additive manufacturing are expensive.

The second obstacle quickly follows, because it relates to the question of what a machine of this price can do. Along with being expensive, metal additive manufacturing machines typically are also constrained in the sizes of parts they can produce. Build volumes smaller than a 12-inch cube are common.

America Makes, the U.S. government institution founded to support the advance of additive manufacturing, recently funded a project aimed at reducing the cost of adoption for additive manufacturing. Optomec, the maker of additive manufacturing equipment in Albuquerque, New Mexico, used this funding to design an additive system that would run within a low-cost machining center. This retrofittable system not only addresses the first obstacle—that is, America Makes’ focus: the cost—but it also addresses the second obstacle, because this additive manufacturing system could be added to any machining center, including a large one.

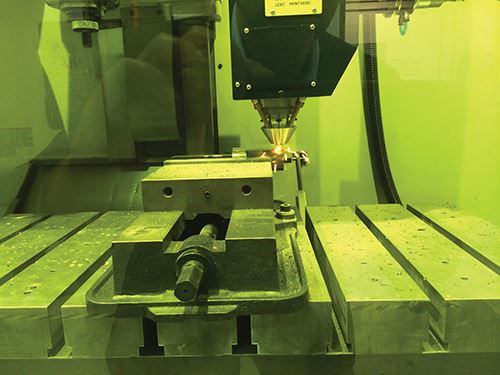

Optomec, unlike some additive manufacturing equipment suppliers that make powder-bed systems, makes machines that are powder fed. In its Laser Engineered Net Shaping (LENS) system, metal powder is fed through a deposition head and fused into precise, complex shapes with a laser. Because the head conveys the material, it allows additive manufacturing to be performed anywhere the head can travel within the machine. The technology, originally developed by Sandia National Laboratory, has been applied not only for growing near-net-shape metal parts and features, but also for making repairs and modifications to existing components.

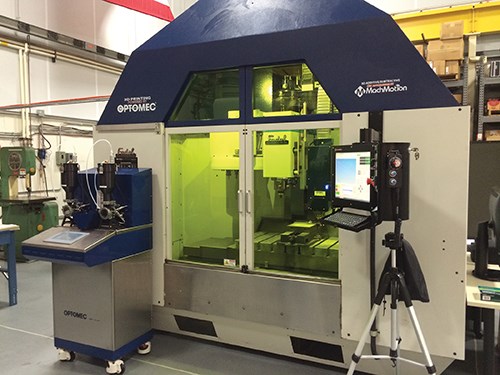

Now, the promise of being able to apply this technology within a CNC machining center potentially brings down its cost. Specifically, it reduces the cost of the platform needed to apply the LENS technology, because any machining center that is still serviceable could be retrofitted to deploy it. At an event at TechSolve, the manufacturing and machining consultant in Cincinnati, Ohio, Optomec recently showed how the new, retrofit version of its technology had been applied to a Fadal vertical machining center that was approximately 20 years old.

Assisting in this effort was MachMotion, which became a partner in the development of the retrofit additive system. This machine integrator and control technology supplier developed a CNC unit that combines control over additive and subtractive operations. (The more modern control also allowed the machine’s subtractive performance to improve.) MachMotion also mounted the LENS head, integrated the feeders delivering metal powder to this head, and—significantly—added laser safety features such as a hood for enclosure and tinted window glass.

Again, reducing cost was the aim. That is why Optomec staff members say they did not see the “hybrid” possibility for this machine at the start. The initial plan was to remove the machining spindle and replace it with the additive head. But it quickly became clear that this was unnecessary—the head could be mounted to the side of the spindle so machining capability could be preserved. Thus, the retrofit machine can do what many new additive machines can’t: It can build additive parts and also complete them through machining. (Other companies have had this idea, too. Various machine tool builders have now introduced hybrid additive/subtractive machines.)

This retrofit concept already does have a user, Optomec says. The Galisano Institute for Sustainability at the Rochester Institute of Technology is applying an additive-equipped VMC to remanufacture and repair damaged components. In these applications, material is layered onto a worn or damaged part using the additive head, then it is machined to finish tolerances in the same cycle using the machine tool’s native spindle.

Meanwhile, testing of this new machine concept will be performed by TechSolve using the modified Fadal VMC. Technicians at TechSolve are using the machine to build various part types in various alloys. Operating costs and operator training requirements are two factors being evaluated, as are questions more directly related to the performance of the machine, such as: How will metalcutting fluids affect the additive build process? And: What effect will metal powder have on the ballscrews and other components? Obtaining answers to questions such as these is part of the final phase for Optomec and MachMotion. After that, they hope to be ready to apply this technology to other machining centers—including potentially any machining center owned or specified by a company ready to convert that old machine into a resource for additive manufacturing.

Related Content

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreHigh RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=970;quality=90)