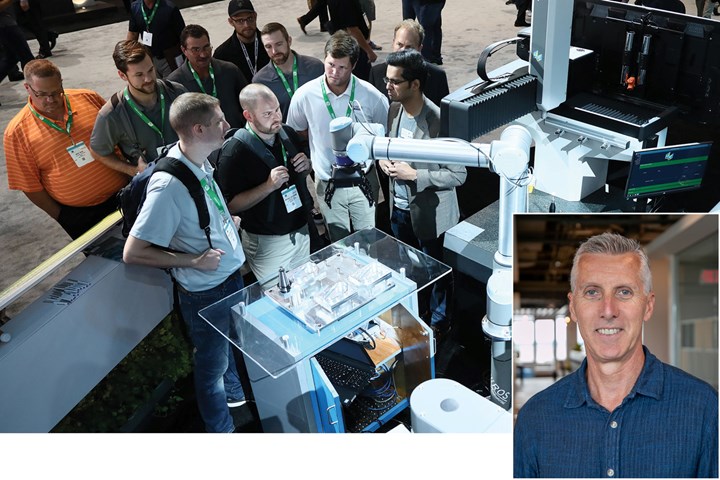

Doug Woods and the Search for “Wow!” and “How”

The President of AMT – The Association For Manufacturing Technology, says that manufacturers are facing challenges as work opportunities are growing – thanks to reshoring, on-shoring and direct foreign investments – and the workforce is shrinking. To face this reality, whether it is additive, augmented reality, generative design, or any number of other technologies, implementing digital manufacturing is essential.

Share

Doug Woods is the president of AMT – The Association for Manufacturing Technology – the organizer of IMTS. As such, you might think that Woods is a guy who knows all about organizing massive events like IMTS and participating in committee meetings and the like.

That’s not wrong, but that’s just a small sliver of what he knows about.

Woods began his career as a manufacturing engineer and worked his way up through jobs including director of Quality, director of European operations, CEO and president for firms involved in tooling, automation, special machines, contract machining and more.

In other words, he’s probably been where you are.

And he’s been attending IMTS for decades, back to a time in the late ‘70s when he was an apprentice toolmaker working in his grandfather’s shop.

“One of the worst parts of my great job at AMT occurs at IMTS.”

Which certainly seems like an odd thing to say.

But Woods explains, “Before I worked at AMT, I would use multiple days at IMTS covering every inch in every hall, asking thousands of questions in all the booths about the things that I would see: what does it do; how do you do it; what does it cost?

“There are so many different kinds of technology and different applications – you’ll never know where it will be. Sometimes there will be a big sign: ‘NEW THING HERE.’ But sometimes there is someone who has a different fixturing approach or a probing technique or a way to setup their screens that isn’t so obvious. I miss the time finding things like that.”

(Not that you’re unlikely to see him in the aisles of McCormick during the next several days.)

While IMTS historically occurred every two years, IMTS 2020 was canceled due to the global pandemic.

Woods says that since 2018 there has been “a huge uptick” in manufacturing in the U.S., in large part as a result of the supply chain problems that COVID-19 caused.

Consequently, there has been significant developments in the areas of automation and digitalization.

“I hope that people say, ‘Now I know how to do that,’ whether it is putting in some new automation or setting up a molding machine or getting that software package to work with the coordinate measuring machine.”

Digital Manufacturing Realized

You may have noticed that the tagline for the Show is “Digital Manufacturing Implemented.” And you may have figured that this was something that some marketing person came up with.

But Woods emphasizes that manufacturers are facing challenges as work opportunities grow thanks to reshoring, on-shoring and direct foreign investments. One of the biggest challenges is the number of workers shrinking. To face this reality, whether it is additive, augmented reality, generative design, or any number of other technologies, implementing digital manufacturing is essential.

“Many people know they’re supposed to be doing something with smart manufacturing, digital manufacturing, Industry 4.0 or whatever you call it,” Woods says. But he acknowledges that plenty of people aren’t sure just how they are supposed to do it.

"One of the great things about IMTS is that there are people there who can show you how,” Woods says.

And on the subject of people, Woods says that at every IMTS he’s attended – whether as an attendee or exhibitor – he has found that there are plenty of people he’s been able to talk with who are facing similar issues, which can help lead to solutions.

Two Words

There are two words Woods hopes IMTS visitors come away with: Wow and How. (He apologizes for the rhyme.)

As for the first, he says, “In my time at IMTS over the years, I’m wowed by the size, the quality, the experience, the number of people and the amount of equipment.”

And for the How, “I hope that people say, ‘Now I know how to do that,’ whether it is putting in some new automation or setting up a molding machine or getting that software package to work with the coordinate measuring machine.”

Related Content

Solid Diamonds and a Speakeasy: Meeting Q-Mark Metrology

Q-Mark has built its metrology business by providing what customers need, when they want it. This goes for its IMTS booth, too, with free drinks alongside custom technology.

Read MoreTrak Machine Tools Lathes Offer Compact, Heavy Duty Performance

IMTS 2024: The Trak TC2 and the Trak TC820si are compact lathes designed for production applications.

Read More6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreRoyal Products Introduces Versatile Three-Jaw Chuck

IMTS 2024: Royal Products features a Three-Jaw Chuck for CNC workholding, designed to reduce setup time between jobs and for the utilization of a range of top tooling.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)