Digitalization and Multitasking Accelerate Prototyping

Protolabs’ Mazak Integrex multitasking machines facilitate efficient automation of the prototyping company's high-mix, low-volume workload.

Share

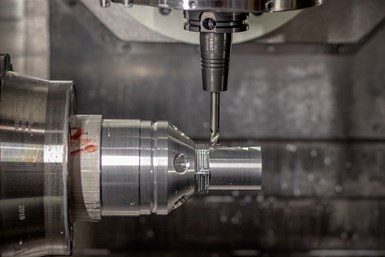

A fleet of identical Mazak Integrex i-100 Bartac-S Multi-Tasking machines improves job scheduling flexibility for Protolabs’ high-mix, low-volume work. All images courtesy of Protolabs.

Production forecasting can be more of an art than a science at Protolabs. The company deals with tens of thousands of different customers yearly, and orders to its machining segment average only three parts. With a range of capabilities that includes machining, injection moldmaking, 3D printing and sheet metal services, the company relies on a specially developed digital thread and versatile machine tools to keep lead times to a matter of days.

Protolabs began its digitalization journey when company founder Larry Lukis developed software for accepting customer CAD models and applying the data throughout the manufacturing process. Customers upload CAD models to the company’s website, choose material and finishing options, and learn how these options impact part lead time and manufacturability. According to Mike Kenison, Protolabs’ vice president and American general manager, digitizing the manufacturing data flow from initial order to completed part results in lower non-recurring costs for the first-part process compared to traditional manufacturers.

“We never know what orders are going to come in, so we always have extra machines and extra capacity available,” Pedersen says. “That’s how we make this work.”

All this smart technology has led to Protolabs filling a niche as a high-mix, low-volume prototype manufacturer. Meeting this niche in a timely manner can be difficult with CNC machines, but adopting a fleet of identical multitasking machine tools has gone a long way to keeping lead times short.

A 4.4-inch (111-mm) main spindle bore accommodating bar ranging to 4 inches (101 mm) in diameter; a 36-slot ATC; and X-, Y- and Z-axis travels of 17.7 by 8.2 by 35.5 inches (450 by 208 by 901 mm) enable Mazak’s Integrex machines to process a wide range of sizes and shapes.

Machines for High-Mix Multitasking

Initially, Protolabs’ CNC segment used vertical milling machines and standard turning centers. When management saw a need to boost turning capacity, it added Mazak’s Integrex i-100 Bartac-S Multi-Tasking machines. These machines have two turning spindles and a milling spindle that together enable full five-axis machining and the ability to machine complex parts in a single fixturing.

Using identical machine tools enables a high degree of flexibility in scheduling. “If we get an order that requires more than one machine, we might run it on two machines instead of one,” says Scott Pedersen, director of manufacturing operations. “At other times, every machine may be running a different part. We never know what orders are going to come in, so we always have extra machines and extra capacity available. That’s how we make this work.”

All the parts Protolabs machines on the multitasking machines are round, and workpiece materials include both hard and soft metals. An intelligent bar loader system simplifies the frequent bar changes that result from the differing material requirements of various parts.

Related Content

-

Custom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

-

Swiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

-

Digitalization and Done-In-One Reign Supreme at BIEMH 2024

European manufacturers may have a different balance of markets than their U.S. counterparts, but the practical challenges they must overcome are often similar — as are the solutions.

.jpg;maxWidth=970;quality=90)