Digital Manufacturing. Implemented.

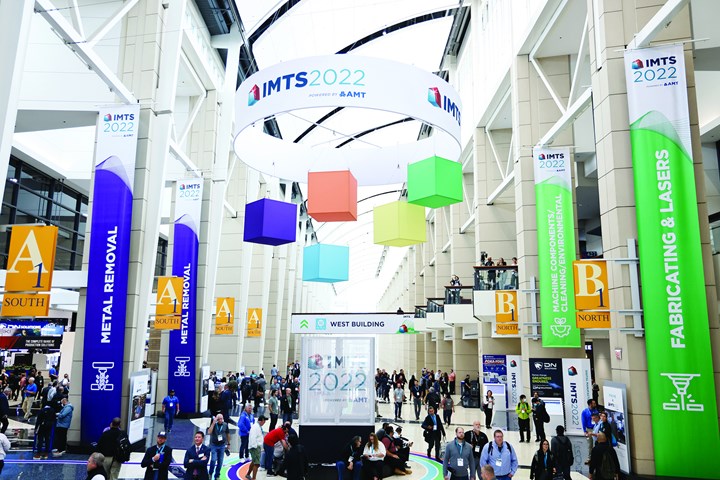

Digital Manufacturing is all over IMTS, in exhibitor booths and in special technology displays. Discover what Peter Eelman, chief experience officer at AMT, thinks of what’s to come at this year’s show.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Peter Eelman’s first IMTS was 1980 and he’s been running the show for the last 26 years. Yet after all this time, AMT’s Chief Experience officer still gets excited about each new exhibition, and this year is certainly no exception. While Eelman is ultimately responsible for the many events around the show, what really gets him going is the technology on the show floors. He has witnessed the transformation from IMTS being largely about selling individual machines to the manufacturing solutions exhibition it is today and thinks the value that brings to attendees grows by the year.

The theme of this year’s show is “Digital Manufacturing. Implemented” and Eelman says that idea is playing out in the vast majority of exhibitor booths. “In the past, you would see a lot of machines and maybe some islands of automation,” he says, “but this IMTS you’ll see how everything fits together. You’ll have a hard time finding equipment that isn’t digitally enabled, and many suppliers can help provide integrated solutions that span from design to finished quality parts.” Attendees can bring a part to the show, explore alternative processes to make it, and come away with a master plan of how to build the best production systems and methodologies to fit current and future needs.

As for alternatives, digital technology enables traditional equipment builders to make parts in new ways, more efficiently and to higher quality standards.

Emerging technologies are also a big component of the IMTS technology mosaic, which bring new possibilities to the production mix. Additive manufacturing is probably the best example of this with IMTS now offering the largest exhibition of AM technology in North America, covering a broad range of 3D-printing processes from some 100 AM companies. You’ll find the Additive Manufacturing Pavilion on Level 3 of the West Building, where you’ll also find AM4U, a multi-use zone on the show floor. AM4U offers industry expert talks and seminars for the adoption of industrial AM, as well as entrepreneurship and business models for start-ups.

But Eelman also points to a variety of other conventional and digital automation solutions that are bringing new possibilities to shops of all sizes to improve their businesses.

A main attraction is the Emerging Technology Center (entrance to North Building, Level 3). The mission of the ECT is to showcase new technologies that are likely to have a big impact on the future of manufacturing. The theme of this year’s ETC is “Space,” and there are two terrific displays to carry that message. First, there is the Giant Magellan Telescope. Ingersoll Machine Tools (Rockford, IL) has won the contract to build the telescope’s support structure, which will be six stories high and weigh 1,800 tons without mirrors or instruments. Ingersoll is displaying state-of-the-art machining technologies involved in the project.

Second, the ETC includes a portion of a 3D-printed space habitat consisting of two-and-a-half floors for a crew of two people. Designed by Denmark-based SAGA Space Architects in partnership with the Swiss Institut auf dem Rosenberg, the unit is intended to be carried into space and then attached to other similar modules with an on-site carbon polymer 3D-printing process.

Also in the ETC, Ingersoll has a robotic cell with both AM and milling capabilities to make doors for the habitat in a single continuous process.

In another key attraction, a dynamic industry collaboration between AMT and ASME, LIVE LAB (next to ETC) delivers expert knowledge, hands-on experiences, and interactive technology on the connected factory, digital twin, big data, AI, and machine learning.

These key technologies will also be on display across IMTS with exhibitors showing very practical applications that are available now. Says Eelman, “IMTS 2022 is replete with multi-tasking CNC and hybrid machines; CAD-CAM, modeling, and simulation software; cybersecurity protocols; metrology systems; and other digitally enabled tools throughout all nine pavilions and in the ETC.”

SAGA’s 3D printed space habitat. Photo Credit: Saga 3D

Related Content

FANUC Details Robotic Vision, ROBODRILLS and More at IMTS 2024

FANUC’s IMTS 2024 booth includes real-time demonstrations that show the abilities of its equipment, including robots, controllers and machine tools.

Read MoreSiemens Software Boosts Efficiency in Parts Manufacturing

IMTS 2024: Siemens Digital Industries Software unveils its NX X manufacturing software, a cloud-based and data-secure CAD/CAM solution for part manufacturing and efficiency.

Read MoreChiron Group Unveils Virtual Showroom & Live Demos at IMTS 2024

Chiron Group combines the best of both worlds at IMTS 2024, featuring live demonstrations of their Micro5 and Mill 2000 machines, alongside a cutting-edge virtual showroom. This innovative approach allows visitors to explore Chiron’s full product lineup without the logistical challenges of transporting large equipment.

Read MoreKennametal Five-Flute End Mill Provides Extended Tool Life

IMTS 2024: Kennametal’s solid end mill is designed to perform in a range of applications.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)