Die Maker Enjoys The Benefits Of Having EDM In The House

As a manufacturer of high volume, precision custom metal stampings for the automotive, computer, farm implement and household appliance markets, this company maintains a substantial in house die making department, empowered by EDM.

Share

As a manufacturer of high-volume, precision custom metal stampings for the automotive, computer, farm implement and household appliance markets, Taber Bushnell Inc.(TBI), maintains a substantial in-house die making department. For the last 12 months, this department has enjoyed the benefits of electrical discharge machining (EDM), in the presence of a Model CX20 submerged wire EDM from MC Machinery Systems, Mitsubishi's EDM division in Wood Dale, Illinois. According to Taber Bushnell Tool Room Manager, Dave Johnson, "We jobbed out EDMing for many years, but we're now very happy to have our own machine and access to this technology in-house."

Taber Bushnell does virtually all of its own die making in-house, just as it performs the majority of its secondary operations on stamped parts inside a 56,000 square-foot facility in Minneapolis, Minnesota.

Mr. Johnson recaps the decision process on EDM. "We'd been aware of the technology for years, of course, but were accustomed to producing complex die cavities in sections, cutting and form grinding the small, hard to access contours by hand. The precision and fit are critical, because we frequently hold tolerances from 0.0002-inch to 0.0005-inch and there's no room for error there."

TBI works in a variety of materials to produce its punch and die sets for the company's highly automated, coil-fed presses, which range from 32- to 600-ton types. These materials include A2, D2, CPM10V, CPM15V,CPM-M4, and tool steels.

Two of the Mitsubishi CX20's operating features were extremely attractive to the particular needs of the Tool Department. An automatic wire feeder allows the rethreading of broken wire and thus enables long periods of unattended operation on the machine, in conjunction with the path retracing software of the on-board computer module.

Additionally, the anti-electrolysis power supply on this wire EDM virtually eliminates the rust and heat-affected zones, especially encountered in submerged machining of ferrous materials.

Another, more subtle feature was very appealing as Mr. Johnson explains, "The Power Master control automatically adjusts machining conditions to compensate for material thickness variations and other die/punch production parameters which we encounter all the time."

In addition to the various toolings produced on the wire EDM, Taber Bushnell also utilizes the machine for the prototyping process. Mr. Johnson comments, "We've made prototype blanks as small as 0.032-inch thick, and just a couple of inches square, as well as a block we recently submerged EDM'd which was over 9 inches tall. We've even set up a 22-inch long punch diagonally and the results were excellent."

Dave Johnson makes the additional comments on why EDM was a positive addition to TBI's tool room. "Maintenance on the machine is minimal and self-policing. The wire processing unit chops up the used wire for later disposal, saving space and time to empty the storage container. It's safer too. Plus, the machine actually tells us when to service certain components and it graphically displays the remaining service life of the consumables, which makes our job easier as well."

Taber Bushnell utilizes a well-known software package to program its EDM and the simple language commands of the machine tool's controller are said to be easily understood by the operator. Mr. Johnson noted that the initial operation for this first-time EDM setup was important and the machine supplier delivered all the necessary instructions to the operator.

"Overall," concludes Mr. Johnson, "Taber Bushnell is extremely happy with the machine, the service and the local dealer support. That's a tough package to beat." MMS

Related Content

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

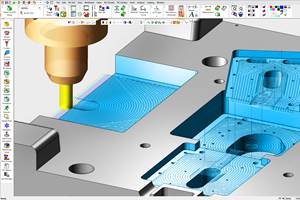

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)