Cutters Halve Cycle Time On Custom Racing Component

Seeking to improve production time on custom-built connecting rods for racecar engines, this shop invested in a light-duty VMC with an eye toward implementing high speed machining. Retooling with cutters from Ingersoll helped make the most of this new capability.

Share

Hwacheon Machinery America, Inc.

Featured Content

View MoreEngines in world-class racecars and dragsters depend heavily on connecting rods, which connect the piston to the crankshaft. For any shop machining these components, it is imperative to ensure that every one is flawless—no voids or inclusions on the inside, no dimensional errors or surface irregularities on the outside. A faulty rod can blow an engine in a split second.

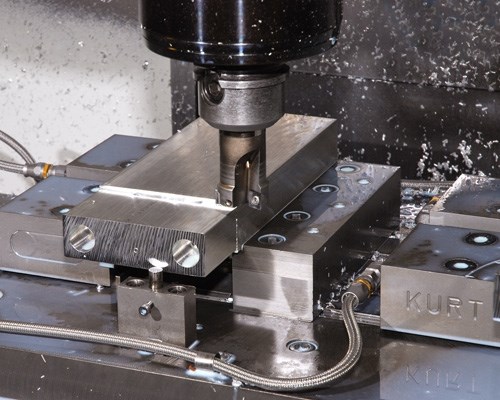

As evidenced by its enviable reorder rate, R&R Racing Products has built a well-earned reputation in top racing circles around the world for the quality of its connecting rods. However, considering the fact that these custom-built components are R&R’s bread-and-butter product, and that each requires milling away more than 75 percent of the feedstock, quality isn’t the only concern for this shop. Maintaining a competitive edge requires ensuring that machining operations proceed as efficiently as possible—a prime factor in the shop’s decision to move into high speed machining last June. Retooling with the help of cutting tool supplier Ingersoll enabled R&R to make the most of this new capability and reduce cycle times on its connecting rods by half.

Located in Grant Park, Illinois, about 50 miles south of Chicago, R&R Racing Products was founded as a general machine shop in 1982 by Mike and Lester Riechers (hence the name “R&R”). By 1995, connecting rods made up the majority of the shop’s business.

Today, the shop is owned by Mike and his wife, Julie. Although R&R also produces oil pumps and other performance parts for the racing industry, demand for its custom rods is sufficient to keep the Riechers’ eight employees busy 10 hours a day, 5 days a week.

“You and I reasonably expect the connecting rods in the family car to last forever, but a drag racing pit crew boss would regard them as replacement parts,” Mr. Riechers explains. “In fact, metal fatigue in a conn rod is a major cause of blown racecar engines. Almost every team inspects the rods thoroughly after every race or time trial. Some replace them every time, just to be sure.”

To illustrate this point, Mr. Riechers cites the example of a typical family Chrysler, which might have a 426 hemi engine designed to run at 435 hp at 5,500 rpm. In a top-fuel dragster or funny car, however, that same block would be souped up to deliver 8,000 hp at 9,000 rpm. The connecting rods bear the brunt of the punishment when that engine revs up.

While most connecting rod manufacturers start with forgings, R&R starts with solid aluminum billets. Mrs. Riechers explains that one advantage of using billets is that the shop doesn’t need to trade off end-use properties for improved forging characteristics, despite the fact that they require significantly more machining than forgings. Mr. Riechers adds that aluminum not only saves weight, but also serves as a shock absorber between engine internals because of its lower elastic modulus, easing impact loads and G forces throughout the engine block.

Additionally, the material itself—a proprietary aluminum alloy that the Riechers claim has better mechanical properties than standard alloys—plays a key role in the high quality of the company’s connecting rods. “We’ve dubbed in ‘unobtanium,’ so it’s unique,” Mrs. Riechers says. She won’t divulge the material’s composition, but she does note that it is somewhat like 7075 aircraft alloy and machines like a typical T-6.

From 1992 until last summer, the machining process consisted of milling the outline, the front side and the back side of a pair of rods before knocking down all sharp edges with a corner mill. Milling the outline with a five-flute corncob-style cutter was the heaviest hogging operation and took 28 minutes. Then, the front side was milled with a 1 1/2-inch, eight-flute face mill. This operation took about 12 minutes. The back side, done with an older Ingersoll HiPos cutter, added another 11 minutes, while roughing off the edges with a carbide wood router took 4 minutes. Altogether, total floor-to-floor time for each pair of rods added up to 55 minutes, and 75 percent of the original billet wound up as chips.

Seeking to improve efficiency by moving into high speed machining, the Riechers added a light-duty VMC with a 12,000-rpm spindle to their equipment inventory. The question then became: How best to tool it? The couple knew different cutting tools would be necessary not only to leverage the new capability, but also for safety. For answers, Mr. Riecher turned to Ingersoll product manager Konrad Forman, whom he had befriended years before when Mr. Forman was a field rep and Mr. Riecher’s business was in its infancy.

“We didn’t ask anyone else,” Mr. Riechers says. “I like Konrad because he knows tooling, and he works conservatively to optimize an operation. We’re wary of guys who come in with something new and push it to the limit right away.”

Mr. Forman recommended three separate Ingersoll tools designed for high speed machining, which is characterized by the use of higher feed rates and shallower cuts to remove metal faster without overloading a light-duty machine or tool. These include two different diameters of the Aluminator end mill for the first and third operations; the 1 ½-inch Hi Pos+ face mill for the second operation; and the FastBreak rounding tool for edge-rounding, the final step.

Mr. Forman then worked with the R&R team to gradually ramp up feeds and speeds, taking time between steps to show how quietly the operations ran, how freely the tools cut and how chip clearance had improved. The tools reduced cycle times for each operation by about 50 percent. As a result, total cycle time for a complete set of rods decreased from 55 minutes to 28 minutes. However, time savings wasn’t the only benefit provided by the new tools—they improved tool life and surface finish as well. “The smoother finish removes still more potential stress raisers on components that are certain to see a lot of stress,” Mr. Riechers says.

According to Mr. Forman, the Aluminator’s better performance stems from a combination of ground and polished inserts and a high positive-rake geometry. “The ground and polished inserts deliver the better finish and edge life, and the free-cutting presentation geometry reduces cutting force and aligns the vectors more axially, which protects the spindle,” he explains. “Large gutters provide plenty of room for chip clearance, a key factor in high-feed milling of a long-chipping material such as aluminum.”

The Hi-Pos+ cutter employed to machine the back side of the rods combines double-positive geometry with a helical cutting edge, which induces a cleaving-type cutting action. A curved cutting edge eases the insert into the workpiece, reducing cutting impact forces by 40 percent, Mr. Forman says. “On the micro level, it’s much like the way an angled blade on a sheet-metal shear cuts just a portion at a time rather than slamming into the sheet all at once,” he notes. “This permits very high feed rates while keeping cutting forces—especially impact forces—in check.”

With R&R now fully equipped to take advantage of its high speed machining capability, Mr. Riechers and Mr. Konrad are working on two new projects: a line of titanium connecting rods and air-cooled aluminum cylinders for Porsche race cars. The latter job is further along—the shop has been making the cylinders for about 5 years, but needs to improve efficiency to respond to increasing overseas demand, Mr. Riechers says. The titanium connecting rod project is in the early development stage in both design and manufacturing. “We’ll be hogging the titanium rods from billets, just as we are with aluminum, which will be a manufacturing challenge,” Mr. Riechers says. “It’s a metal we’re not familiar with, but I know Konrad has dealt with it elsewhere.”

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreBriquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreHigh-Feed Machining Dominates Cutting Tool Event

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)