Controlled Welding Process Joins Metal in a Flash

Manual methods were not accurate enough for joining advanced high-strength steel (AHSS), so Taylor-Winfield Technologies worked with a Rexroth distributor to devise a technique using a motion controller and hydraulic drives for better precision.

Share

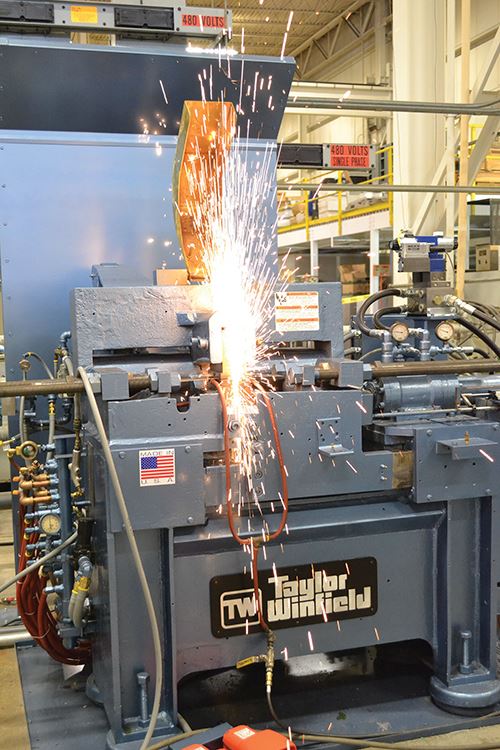

There’s a growing need for flash-butt welding in industries such as aerospace, automotive, appliance and others that require seamless joints in high-strength-metal products. There’s also a need for greater accuracy and controlled timing within this industrial process. Taylor-Winfield Technologies Inc., a welding and metal-joining technology OEM in Youngstown, Ohio, worked with Rexroth distributor Hydrotech Inc. (Cincinnati, Ohio) to devise a technique that uses a motion controller and hydraulic drives to meet these needs while becoming more cost efficient.

According to Taylor-Winfield, technological innovations have been improving productivity and quality in welding operations. This is especially true in flash-butt welding, which uses electrical resistance to heat the ends of two metal pieces and forge them together into continuous coils, wheel rims, rods, bandsaw blades and other shapes that require seamless joints at parent-metal strength.

Using early machines, the distance between the two workpieces was manually controlled during the flash-weld process. The operator would dial in the proper current, and a cam would control the speed of the moving platen, drawing the workpieces together. However, today’s advanced high-strength steel (AHSS) products need much greater accuracy and controlled timing—down to thousandths of an inch and a few milliseconds, respectively—than the manual control can provide, Taylor-Winfield says. Instead, it takes automation to precisely move the workpieces together at exactly the right speed and temperature, creating a strong, homogeneous weld.

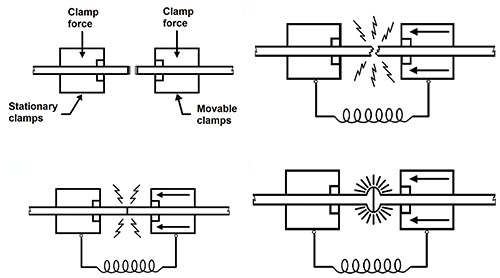

Flash-butt welding is a two-stage process. The first stage is the “flashing” phase, in which electrical current is applied to two workpieces separated by a small gap of about ¼ inch, depending on the material. As the two workpieces are brought together, electricity arcs across the interface, and the temperature ranges from 600 to 900°F at the ends.

The second stage, known as the “upset phase,” begins once the ends reach the required temperature for the material. A moving and a stationary platen push together the two workpieces with enough force that the ends forge together. This action “upsets” the material, forcing the excess and impurities from the top and bottom of the joint. This material is subsequently removed by a trimming process to reach parent-metal thickness.

Because the flash-butt welding process removes irregularities and impurities, it can successfully join a wide variety of materials, including narrow and thick shapes, wide and thin metal sheets, and ferrous and nonferrous materials. The key to making a successful flash-butt weld is precisely controlling the moving platen and electrical current of the two workpieces, Taylor-Winfield says.

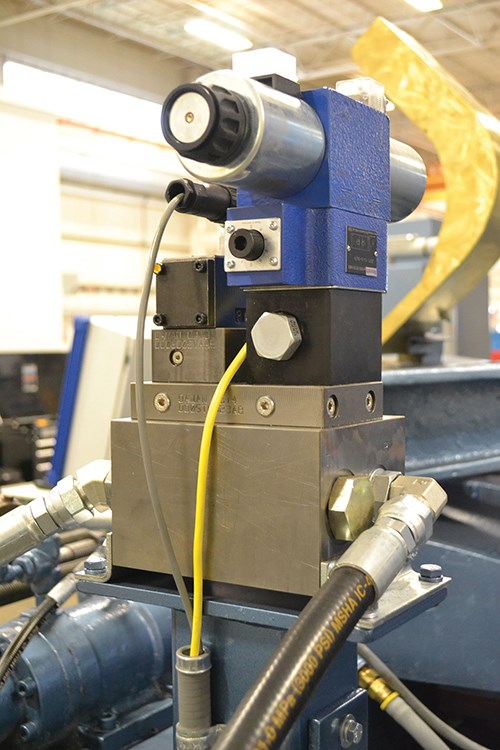

One solution is to replace the cams with electric servodrives and use multiple PLCs to control the process, but that can result in a machine that is too expensive to be widely adapted. Instead, Taylor-Winfield decided to use just one Rexroth IndraMotion MLC L45 motion logic controller to operate a proportional Rexroth hydraulic servo valve in a closed-loop automation system in combination with its patented “forced-freeze” welding process. This solution moves the workpieces together with precise accuracy and timing, can be adapted to various applications, and is a cost-effective way to join AHSS, the company says.

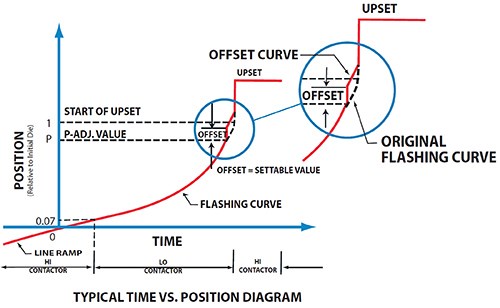

To begin the welding process, the operator loads a welding curve that depicts the logarithmic relationship between the two workpieces in terms of time and position into the controller. Then, he or she can use the Rexroth touchscreen IndraControl VPP 40 human machine interface (HMI) to select the proper weld schedule and modify the weld curve for the particular material. During the flash phase, the position of the mobile workpiece accelerates dramatically to generate forces ranging to 1,000,000 psi to forge the workpieces together. The IndraMotion MLC controller receives position signals from a transducer through a closed central loop and initiates a position change by activating the Rexroth hydraulic power unit. A Rexroth 4WRPH proportional directional valve activates a linear positioning cylinder that moves the platen containing the mobile workpiece toward the stationary workpiece. The overall weld schedule lasts from 2 to 30 seconds, depending on the material.

In flash welding, smooth acceleration of the moving platen is necessary to accurately forge together the workpieces—the platen shouldn’t freeze in position. However, Taylor-Winfield’s forced-freeze welding process purposefully advances the moving platen linearly during the flashing cycle. For example, the workpieces are offset by 50 microns for 2 milliseconds. During the offset time, the joule heating dramatically increases, similar to when the standard freeze occurs—that’s why it’s called a forced freeze. The platen movement resumes into the “upset” phase of the welding cycle to complete the process, and the additional heating improves the weld quality.

Taylor-Winfield worked with Hydrotech Inc. to develop the event-driven motion control profile for the controller. This MLC controller is loaded with Flex Profile, a motion programming platform from Bosch Rexroth that adapts segment-based cam technology to simplify defining motion segments for electronic and hydraulic motion control tasks.

According to Hydrotech, one of the benefits of using the IndraMotion MCL is that programming is exactly the same for hydraulics and servodrives. The Flex Profile function provides an object definition that enables translation of the traditional cam-based model and its associated cam tables to a schedule-based, event-driven model. Hydrotech worked with Bosch Rexroth hydraulics experts to create a motion profile for the hydraulics used in the forced-freeze process.

Taylor-Winfield says the integration of the IndraMotion MLC for hydraulics platform with Rexroth hydraulic components enabled it to achieve the required accuracy and precision necessary for its flash-butt-welding applications. Moreover, the forced-freeze flash-welding process can be implemented on new machines and can be added to existing flash-welding machines as a controls upgrade. Additionally, with the use of hydraulics, the solution can be scaled to any size application without adjusting the controller.

Related Content

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)