Consider Passive Damping To Bore Deep Holes

The old bromide, 'an ounce of prevention is worth a pound of cure,' comes into play for preventing chatter when boring deep holes.

Share

The old bromide, “an ounce of prevention is worth a pound of cure,” comes into play for preventing chatter when boring deep holes. In general, by the time a workpiece is set up to be finish bored, most of the value that the shop brings to the raw material has been added. At that point in the process, it is in the shop’s interest to reduce the chance of messing up the finish pass, scrapping the part and having to start over.

For most deep hole boring operations—4× length to diameter and greater—the enemy is chatter. As any machinist knows, chatter is insidious. It seems to show up sporadically, and the deeper the bore the worse it can be.

Chatter results from vibration between the cutter and workpiece interface. It is exacerbated by deep hole boring because as the length to diameter ratio of the boring bar increases, vibration is more easily transferred to tool tip. For example, increasing the length of a bar from 4× to 10× the diameter gives 16 times larger deflection for a bar taking a constant cutting force.

Instead of smoothly lifting and breaking a chip, the tool tip vibrates, causing the dreaded chatter pattern to appear on the workpiece surface. This is bad news for tight dimensional accuracy and low Ra surface finish specs.

The key to reducing or eliminating chatter is to minimize vibration during the machining operation. There are several techniques known to enhance the dynamic stiffness and stability (chatter resistance) of long boring tools and allow an increase of overhang—up 14× length to diameter.

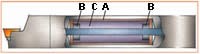

According to boring bar specialist Teeness, a Sandvik Coromant (Fairlawn, New Jersey) partner, the most common and cost effective way to enhance dynamic stability in long overhand boring bars is the use of passive dynamic vibration absorbers within an inertial mass or pre-tuned bar. These pre-tuned bars consist of a heavy tuning body suspended inside the boring bar on two rubber bushings at each end of the tuning body. A specially designed oily liquid surrounds the body.

If vibration occurs during the machining process, the tuning system will come into play, and the kinetic energy of the bar will be absorbed into the tuning body. As a result, vibration is minimized, and cutting conditions can be optimized. According to Teeness, it is quite feasible to machine with tool overhangs of 10× diameter with these bars.

Assuming that vibration and its resulting chatter will occur, using tooling that offsets it is prudent. Rather than reduce cutting efficiency through speed and feed manipulation, damped boring bars can keep cutting conditions optimized on finish boring operations.

Related Content

-

Darex Adds End Mill Attachment to Drill Sharpener

This LEX600 end mill attachment enables users to sharpen the primary and secondary grind on the tips of two-, three- or four-fluted end mills up to 5/8".

-

Finding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

-

Mikron Tool's Drill Provides High Performance in Titanium

The new CrazyDrill Cool Titanium series is designed to provide controlled chip removal, high drilling speeds and long tool life.

.png;maxWidth=300;quality=90)