Compact Rotary Table Features Large Through-Hole

This rotary table was developed to deliver the requisite through-hole diameter in a more compact overall size.

Share

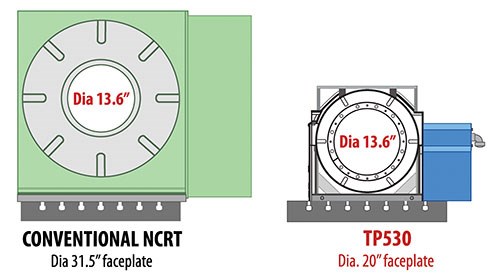

As the oil, gas and aerospace markets have grown, so too has the size of workpieces those industry segments require. Machining of tubes and pipes, for example, calls for NC rotary tables with sizeable through-holes to accommodate large-diameter stock. The Kitagawa-NorthTech TP530 was developed to deliver the requisite through-hole diameter in a more compact overall size than comparable rotary tables so this type of work can be performed on smaller machines.

The TP530 has a 20-inch-diameter face plate and offers a through-hole diameter of 13.6 inches, which has previously been available only with rotary tables having a 31.5-inch face plate. It is said to be four times smaller than conventional 31.5-inch versions as well as 484 pounds lighter while providing the same through-hole capacity. This design enables work to be performed on smaller-sized machine tools.

The rotary table also offers a low Z-axis centerline height. Bringing the centerline of the workpiece closer to the table minimizes machining vibration and workpiece deflection. Plus, it enables large-diameter work to be performed on machines that don’t have significant Z-axis travel, which, in some cases, can preclude the purchase of a bigger machine. In addition, shorter, stouter tools can be used because the distance from the top of the rotary table to the workpiece is less than conventional rotary tables. Shorter tools are less prone to deflection and enable shops to realize more aggressive cutting operations. This feature complements the rotary table’s high clamping torque of 4,499 foot-pounds.

Related Content

-

Workholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Navigating Large-Scale CNC Machining: Suburban Tool’s Niche Strategy to Stay Competitive

Facing increasing competition from lower-cost imports, Suburban Tool made a move toward large-scale, in-house machining. By identifying a niche in large, precision angle plates and tombstones, the company has strengthened its ability to control quality and protect its reputation.

.jpg;maxWidth=300;quality=90)