Collet Blocks: Hydraulic or Pneumatic?

Collet-style workholding devices, such as collet blocks, offer a number of benefits, but which style is most appropriate for a given application?

Share

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreCollet-style workholding devices, such as collet blocks, offer a number of benefits. Collets automatically center workpieces, an action that reduces setup time by making their center points known locations. Unlike standard vises or three-jaw chucks that provide minimal points of contact with a part, collets provide equal gripping pressure around a part’s entire circumference. Expanding collet systems are also available to enable internal gripping of thin-wall parts or delicate materials that might otherwise become distorted using other workholding methods.

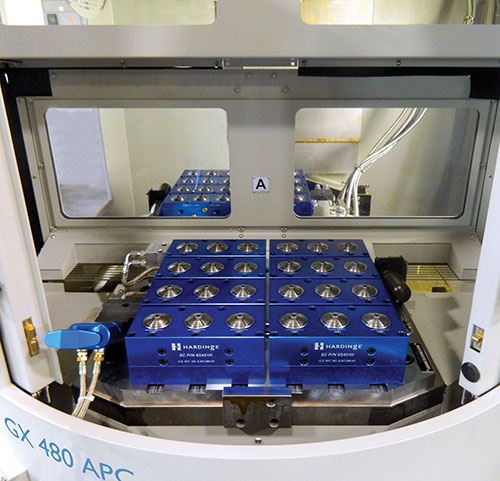

Grouping collet blocks together can enable equipment such as VMCs, HMCs and jig grinders to machine multiple workpieces unattended over long stretches of time. Collet blocks can be oriented horizontally or vertically and can be installed on workholding devices including tombstones, angled fixture plates and rotary trunnion tables. Hardinge, an Elmira, N.Y. manufacturer of machine tools and workholding equipment, offers several collet block models that use standard-sized collets commonly found in many shops, as well as hex-, square- and custom-shaped collets that can hold various non-round workpieces.

The question then becomes: Which style of collet blocks—hydraulically or pneumatically actuated—is most appropriate for a given machining application?

Even though pneumatically actuated collet blocks provide lower clamping force than hydraulic units, many shops prefer to use pneumatic collet blocks because compressed air is often readily available, easy to connect and doesn’t require complex plumbing schemes. In fact, a small, individual air compressor will do the job, although filtered air is recommended.

A simple pneumatic arrangement consists of a subplate onto which the collet blocks mount and a control valve(s) for part clamping/unclamping. Depending on application requirements, a single air valve can be used to clamp and unclamp all parts simultaneously or multiple valves can be installed to independently control individual collet blocks or rows of blocks. Select Hardinge collet block models enable users to internally plumb units together using connector bushings. Models that don’t use connector bushings must be plumbed externally.

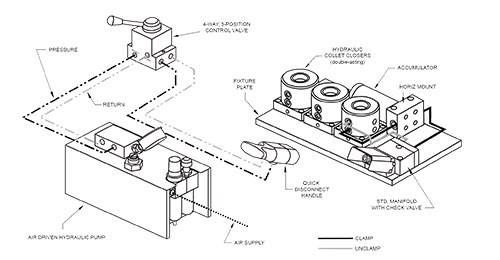

Hydraulically actuated collet blocks require a hydraulic source, but provide higher clamping forces needed for heavy rotation, tapping, threading or off-center machining work. Hardinge says it offers an inexpensive, air-over-hydraulic pump with accessories for shops that don’t have a hydraulic source at the machine. A single two-position, four-way control valve can be used to clamp/unclamp all parts simultaneously. It is also possible to configure multiple valves to control each block or row independently. The control valve(s) mounts on the subplate near the collet blocks and is plumbed to a hydraulic pump located outside the machine.

An optional quick-disconnect system is available for hydraulically actuated collet blocks. This option enables easy preloading of collet blocks with workpieces. Using a quick-disconnect handle with a standard collet block manifold facilitates quick setups because the collet block subplate and pump assemblies are preset and ready to install as needed. However, the collets in a collet block will not maintain their clamped or unclamped position when removed from the manifold unless a check valve is installed in the manifold. In addition, a three-position, four-way control valve mounted outside the machine is required when using the manifold with a check valve to maintain the clamped or unclamped positions with the hydraulic power source disconnected from the subplate. An accumulator is also recommended because it provides a backup reservoir to maintain system pressure if a leak should occur. Accumulators are available in vertical- or horizontal-mount versions and install on the collet block subplate.

Related Content

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read MoreRail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)