Cloud-Based Monitoring Improves Aerospace Manufacturer’s Productivity

Cloud-based machine monitoring from Shop Floor Automations enabled aerospace parts manufacturer Tech Manufacturing to reduce lead times and improve productivity.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

When companies such as Boeing, Lockheed Martin and Bombardier have urgent orders, how can a shop that is already running 24/7 reduce its lead time? This was the problem faced by Tech Manufacturing (Wright City, Missouri), a long-time manufacturer of machined metal parts for the aerospace industry. By introducing cloud-based monitoring from systems integrator Shop Floor Automations (La Mesa, California), Tech Manufacturing was able to pinpoint exactly where productivity issues needed to be addressed to maximize efficiency.

One way the company could have solved this problem would have been to purchase additional machines; however, Jerry Halley, chief engineer at Tech Manufacturing, was interested in finding a smarter, more efficient approach.

“It was clear to me that we needed, first and foremost, a much better understanding of how our machines were actually performing for us in real-time,” Mr. Halley says. “In addition, if we had both live and historical machine performance data available, we should be able to identify any technical or process issues that were detrimental to individual or overall productivity.”

Although this information would be helpful, obtaining machine performance data would require an investment in both monitoring hardware and software. Although Mr. Halley saw the value of establishing a smarter, more connected machine floor, he had concerns about deploying a server-based IT infrastructure to support a CNC monitoring system. Not only would this be technically challenging, time-consuming and expensive, it would also introduce new in-house maintenance requirements.

These concerns were familiar to Greg Mercurio at Shop Floor Automations, who says that many companies think setting up CNC monitoring is difficult and expensive. However, he says, today’s cloud-based solutions enable shops to set it up in less than a day with almost no additional IT infrastructure or maintenance effort. For Tech Manufacturing, there was no need to purchase expensive and locally maintained IT infrastructure, because the monitoring software is on the Internet.

Although cloud-based software such as Scytec DataXchange or Predator Machine Data Collection can easily monitor CNC machines that already have the necessary interfaces to connect to a network and the Internet, there are also ways for legacy machines without a readily available Ethernet port to establish cloud connectivity. Shop Floor Automations uses industrial networking units from Moxa to extend the capabilities and useful life in older CNC machines.

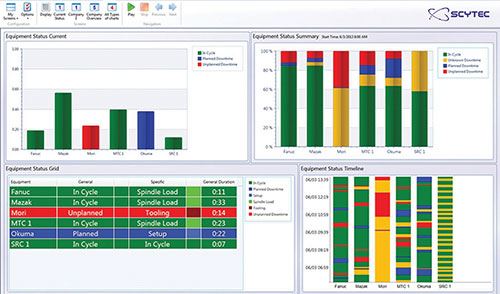

Each CNC machine at Tech Manufacturing is simply connected to the local area network, either through its own native interface or through the Moxa hardware. The information is then relayed to the cloud for immediate analysis and viewing. The Scytec DataXchange software collects a rich set of machine performance data, stores it in the cloud, and in near real-time, presents it in a useful, easy-to-understand way, the company says. Key performance metrics are organized on a visual dashboard, which updates automatically and can rotate through multiple sets of data, so owners and machine operators are able to see exactly how productive each cell is, down to the machine level.

For many companies, this is a “light bulb moment,” Mr. Mercurio says.

“Productivity monitoring can be a vague concept to wrap your head around, but once you see it for yourself with your own machines and with live data, you wonder immediately how you ever operated without that knowledge and awareness.”

The dashboard made it easy for operators at Tech Manufacturing to see immediately where their most glaring issues were. For certain machines, the company found setup times to be unnecessarily long, meaning hours of lost productivity every day. With a relatively simple rearrangement of setup sequence and on/off times, Mr. Halley was able to achieve immediate and significant productivity gains.

Mr. Halley also saw an additional benefit from having comprehensive machine performance data on-hand: better service from CNC manufacturers. With key performance metrics tracked and recorded, service calls can be made with a much higher degree of confidence that a hardware issue is present, and Tech Manufacturing can provide manufacturers with a rich set of data to aid in troubleshooting.

“With our intimate knowledge of how our machines should be performing normally, we find that manufacturers are much more willing to provide support when we request it, because they know we are not wasting their time,” Mr. Halley notes.

Tech Manufacturing says it made the right decision to connect its equipment through the cloud to enable smarter management and maintenance. For instance, Mr. Halley says that getting the CNC machines connected and monitored made it much easier for the company to deliver build-to-print orders with maximum efficiency and lead time. The productivity gains have made up for the cost of deployment many times over, he says.

Related Content

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreCan AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.jpg;maxWidth=300;quality=90)