Closing the Loop

Gathering information is worth it only if it’s put to practical use. Applying measurement data to streamline spiral bevel gear making clarifies the true value of the closed-loop process.

Share

In general terms, “closed-loop machining” involves returning measurement data to design software that automatically adjusts for deviances and sends revised code to the machine tool, ensuring that the end result matches the geometry of the intended goal. When referring to gear design, in particular, the benefits include reduced setups, minimal variation between parts and the high-quality surface finish that grinding is known to produce. As a leading advocate of closed-loop gear machining, Rave Gears of Seguin, Texas, has allowed the concept to penetrate deeply into its comprehensive business model.

“Closed-loop manufacturing is a philosophy as much as it’s a machining process,” says Thomas Alaniva, vice president of the company’s gear division. “It represents a commitment to removing human error from the whole cycle so that the design and finished product align quickly and seamlessly.”

While the closed-loop concept isn’t new, advances in grinding and measurement technology, as well as application of the lessons Mr. Alaniva has learned over the years, have enabled Rave Gears to streamline operations while improving gear quality and reducing production costs.

Making it Beta

It would be hard to find anyone more familiar with the “closed-loop digital topography process,” as it’s also known, than Mr. Alaniva. He was involved in beta testing Klingelnberg’s version of the software—Gleason was also a pioneer in its development—while he was working in the engines division of Honeywell nearly three decades ago. After 21 years in this position, working alongside the son of the system’s creator, Dr. Ing. Soeren Weiner, he then spent six years at Bell Helicopter’s Drive System Center. There he continued to embrace the closed-loop system in designing and manufacturing spiral bevel and hypoid gears, among others. When Rave Gears was launched in 2012 by CEO Nick Patel and President Bruce Roberge, Mr. Alaniva saw an opportunity to continue exploring the potential of the process in an entrepreneurial environment. He was drawn to the two men’s plan to create a high-precision gear manufacturing company serving the aerospace, automotive, oil and gas, racing, and military/defense markets, using the latest equipment, processes and technologies.

“We originally took the path of purchasing a couple of rebuilt machines, but we quickly realized that wasn’t what we wanted to do,” Mr. Roberge recalls, adding that he and Mr. Patel had worked together years earlier at another gear manufacturing company and therefore knew exactly how they did—and didn’t—want to proceed. “We decided to go with buying all-new equipment, and we haven’t looked back since.”

The result is a 20,000-square-foot facility—soon to be expanded—that resembles a showroom as much as it does a shop floor, with brand-new turning, milling and grinding centers from Höfler, Mori Seiki, Haas, Mazak, Mitsubishi, Junker and Studer arranged to create a streamlined workflow. Its latest acquisition is a second massive Klingelnberg/Oerlikon G60 spiral bevel gear grinder, which will support Rave’s continuing development of deep grinding, or grinding gears straight from a solid.

The company has had so much success with deep grinding, in fact, that it has become standard operating procedure for the gears it produces. “We don’t have a gear cutter on the floor that’s used to cut teeth,” Mr. Roberge says. “Grinding gear teeth from solid has become so commonplace for us that it’s no longer remarkable, it’s just the way we go about our work. And the closed-loop process that Thomas has spent so many years studying and perfecting is a big reason for that.”

The Daily Grind

Although many companies offer software for the closed-loop design/manufacture of different types of gears—and other components, as well—the basic concept involves developing a robust design, partially machining the gear with some stock left in place, measuring dimensions that are automatically compared with the original design, making corrections and then completing the machining. By contrast, Rave Gears’ steps involve:

-

Designing the gear

-

Planning the grinding sequence

-

Producing the gear as a near-target value

-

Measuring the result on a 3D gear analyzer and comparing with the original design

-

Calculating the variation between the design and the near-target gear

-

Making adjustments, reinstalling the gear on the grinder and continuing grinding through completion

“It’s basically a system that eliminates mistakes made by operator intervention,” Mr. Alaniva says. “If you close the loop from design through manufacturing and inspection all the way to delivery, there is no subjectivity involved. Everything is black and white, so you’re reducing variation based on hard numbers.”

Beginning with the development of a robust design—one that can produce a simulated contact pattern under load using Klingelnberg’s Kimos/Komet and Gleason’s Gage/Cage software—Mr. Alaniva makes adjustments such as contour changes before loading the resulting machining code into the grinder.

“As I’m designing the gear set, the software is creating the program to actually produce the part on the grinder,” he says. “It simulates a roll test that gives me transmission error, root bending, surface pressure, all the digital data I need to begin machining with confidence.”

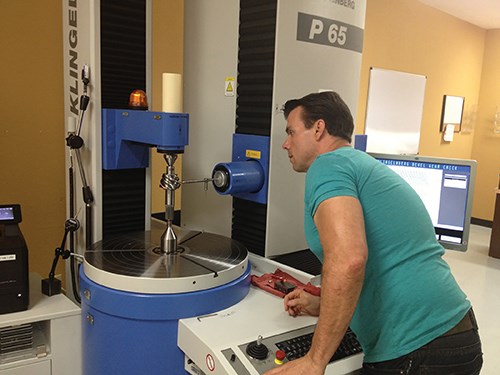

Once the first piece has been ground nearly to completion, leaving a slight amount of stock intact, it is tested on the company’s Klingelnberg P65 3D measuring device to check for process errors. “These are primarily machine errors having to do with calibration,” Mr. Alaniva explains.

The Klingelnberg closed-loop software then runs a simulation correction program, which compares actual testing data with the theoretically perfect part derived in design. The program identifies deviations, runs thousands of hypothetical machine moves to determine the optimal paths, and then automatically sends a revised finishing part program to the machine’s control. After reinstalling the part in the grinding machine, “All the operator has to do is hit a button to accept the corrections,” he says, adding that most closed-loop software produces neutral code that can be loaded into either Klingelnberg or Gleason grinders, for instance. “There’s no chance of ‘fat fingering’ the wrong numbers on the keyboard, or entering a decimal place incorrectly,” Mr. Alaniva says, “You just punch the one button, so human error has basically been eliminated.”

No Going Back

A longtime advocate of the closed-loop gear manufacturing process in his own right, Mr. Roberge says major improvements to the process have come about thanks to advancing technologies and the expertise amassed over three decades of intense practical experimentation and application.

“Gear measurement is far superior to what it used to be,” he says. “We have so much control over our contact patterns that we can predict whether we have a ‘first piece sold’ just by looking at the graphs produced by the CMM. The closed-loop system provides us with what you might call an absolute certainty of the outcome. We have not once encountered a situation where the data produced in our labs did not match the theoretical design within a reasonable and easily correctable margin so that the first gear ground became the first gear shipped. Not once.”

As to the specific improvements made to the closed-loop gear manufacturing process over the past three decades, Mr. Alaniva says it’s more a matter of the desire to embrace new and improved technologies than anything else. Companies that are tied to outdated legacy equipment and stuck in the routine of doing things the same way they’ve always been done will have increasing difficulty competing in a market in which new equipment designs and improved machining processes are tilting the playing field in the progressive team’s favor.

He groups advancements that have improved closed-loop machining into three areas: grinders that are more accurate than ever before, with more powerful drives behind them; measuring systems that are so precise they basically eliminate subjectivity and human error; and closed-loop software that features a graphical user interface that is more conversational and user-friendly than past versions—light years beyond the DOS-based software introduced more than three decades ago.

Mr. Alaniva also points to major improvements in abrasives technology. Along with more powerful, rigid and stable grinding machines, wheel bonds and grain structures have been developed that perfectly match the action and desired outcomes of deep grinding. This has resulted in gears that routinely meet the tolerances of industries such as aerospace and high-end automotive, using a process that is increasingly cost effective.

This has had a tremendous effect on Rave Gears’ relationship with its customers from an operational standpoint. “Not that long ago a 12-hour setup for ground tooth development was considered to be efficient, and that didn’t change for years,” Mr. Roberge says. “Now, by eliminating setups on cutting machines and doing all our work on the grinder, we are regularly setting up our machines and beginning production within three hours. And let me be clear, we’re talking about developing a finished spiral bevel gear the first time through, while we worked 12 solid hours in the past and ended up with a part that wasn’t acceptable, which meant you had to start all over again.”

Lessons Learned

The company’s commitment to deep grinding—as well as the closed-loop system—is helping bolster its reputation for producing complex gearing quickly, accurately and economically, according to Mr. Roberge. “People call wanting a quote for deep grinding 120 sets of gears—three ring gears and two pinions, for instance—and we’re able to do it for a fraction of the cost that we once were,” he says. “You’re not going to get the job if you have to charge them for five or six operations. When you combine the closed-loop process with deep grinding you can get everything done in one operation. Plus, turnaround time has been reduced. Jobs that previously took days to machine can now be completed in hours.”

Another concern that’s been eliminated thanks to deep grinding, augmented by the efficiencies inherent in the closed-loop process, is the uncertainty surrounding heat treat, Mr. Alaniva says. “When you practice the closed-loop system to the extent that we do, basically going from womb to tomb, you’re able to reduce more than 90 percent of your variation, even predicting your heat treat results. Deep grinding induces stresses in a uniform manner throughout the part, which allows us to accurately foresee how it will react during heat treat. If you want great gears coming right out of heat treat, you can’t do any better than closed-loop.”

Rave Gears is not alone in adopting the closed-loop process or grinding gears from solid, but according to Mr. Roberge, “we’re the only one I’m aware of that has made this combined approach our very reason for being. We don’t see the market the same way that we used to. There has been a major shift and a new paradigm is beginning to emerge. We are happy to be on the leading edge of that shift.”

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More