Clamp Bore Face Grinding and Honing Creates Higher-Quality Gear

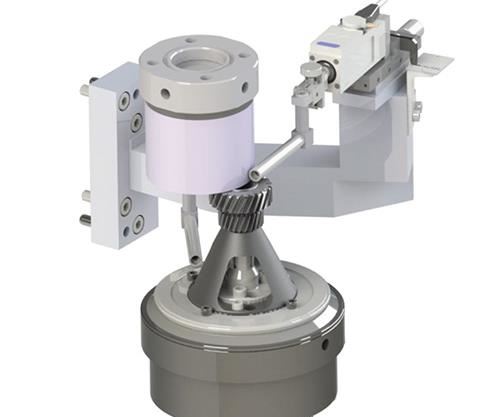

Nagel's ECO 40 hone and SPV clamp bore face grinder helped Global Gear and Machining to produce gears with stringent bore-to-face perpendicularity tolerance.

Share

One way of producing high-precision gears is to perform honing and double-disc grinding operations. However, for a new automotive pinion gear program, Global Gear and Machining discovered that double-disc grinding could not achieve the desired bore-to-face perpendicularity tolerance its customer required. Also, as a batch process, double-disc grinding was not conducive to single-part flow, which is necessary to produce gears on an as-needed basis versus keeping a large stock inventory. By adding a fully automated Nagel Precision ECO 40-3 honing machine and SPV clamp bore face grinding machine, Global Gear was able to achieve its objectives.

For more than 25 years, Global Gear and Machining of Downers Grove, Illinois, has served makers of precision engine and transmissions, including Allison Transmission, American Axle, Navistar, CNH and more. With more than 110 employees and 132,000 square feet of manufacturing space, Global Gear specializes in helical and spur gears; pinion gears; planet gears; shafts with gears; and high-value-add assemblies with gears for off-highway, agricultural and automotive markets. Capabilities include turning, outer- and inner-diameter grinding, honing, clamp bore face grinding, gear-tooth grinding, shot peening, shaving, and shaping. The company can accommodate volumes ranging from 2,500 to 500,000 gears per year.

According to Global Gear’s engineering department, transmission makers are under constant pressure to reduce noise and vibration to enhance ride quality and fuel economy. Wobble of the gear’s involute profile contribute to transmission error and thus potentially to gear noise. Wobble occurs when the axis of the bore is not aligned with the axis of the gear.

In order to eliminate wobble in the final gear-grinding operation, a bore-to-face perpendicularity of less than 10 microns is critical, as the gear is piloted off of both face and bore. According to Nagel, honing then double-disc grinding the gear faces does not impact the bore-to-face perpendicularity, since both faces are finished simultaneously. The double-disc grinding process basically carries the perpendicularity over from the prior operation. This process yields about 0.025-mm bore-to-face perpendicularity, which is insufficient to control involute wobble.

At Global Gear, the bore is first honed by the Nagel ECO 40 to a very tight surface finish with tight tolerances, and then the part is clamped on the bore and located against the face to finish the opposite face. The part is then flipped 180 degrees to finish the other face while clamping on the same bore. In-process gaging permits tight control of thickness. The table below illustrates typical quality achieved by the combination of honing and clamp bore face grinding.

| Material | Forged Steel/Powder Metal |

| Finish Area | Bores and Faces |

| Stock Removal | 0.025 to 0.100 mm |

| Bore Diameter | 30 ± 0.005 mm |

| Surface Finish Ra | 0.10 μm |

| Flatness | 0.003 mm |

| Bore to Face Prep. | 0.005 mm |

| Roundness | 0.005 mm |

| Straightness | 0.005 mm |

| Cross Hatch | 45 to 65 degrees |

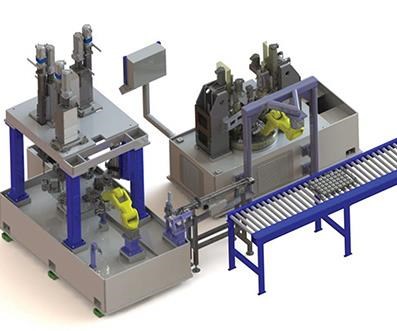

In the cell shown in the image gallery above, parts are first fed to the Nagel hone by a conveyor. A robot picks two gears and simultaneously loads/unloads the cardanic fixtures while the machine is running. The honing itself is a three-pass operation consisting of roughing, semi-finishing and finishing. The part is measured in-process after each honing step, and tool wear is compensated for without any operator intervention.

Honed parts are transported to the SPV clamp bore grinder via an integral conveyor. The grinder consists of four stations: loading/unloading, grinding of the first face, flipping the part 180 degrees and grinding of the second face. Finished parts are loaded on the exit conveyor. Each grinding station is equipped with in-process gaging to control the gear’s thickness.

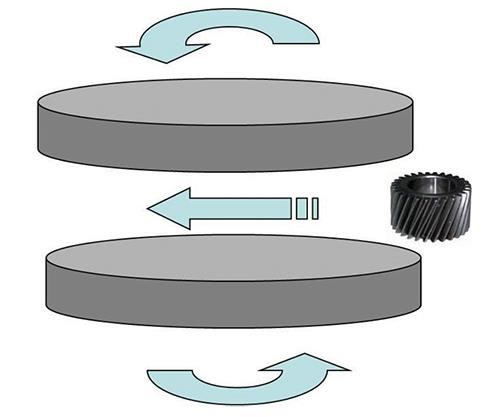

According to Nagel, its SPV clamp bore gear grinder differs from conventional grinding operations. Instead of depending on rigid fixturing as well as the accuracy of the grinding wheel’s position relative to the part, the SPV utilizes free-cutting cup wheels, and the tool self-dresses and conforms to the contours of the part. This automatically compensates for inaccuracies in the machine. During this operation, the gear is clamped on the bore’s internal diameter and rotated in a direction opposite that of the cup wheel at high surface speeds. To prevent variations in flatness or axial runout when finishing flat surfaces, the cup-wheel tool substantially overlaps the surface of the part during machining. The machine can remove material ranging from a few microns of stock to a few hundred microns very quickly, the company says.

The illustrated cell has an output of one part every 12 seconds; however, single-spindle SPV machines and smaller hones are available for lower volumes and high change-over scenarios.

According to Global Gear, in addition to providing excellent bore-to-face perpendicularity, the Nagel hone and clamp bore face grinding process fit in the single-piece workflow adopted in the cell. Global Gear says it has now been able to achieve zero defects in this gear cell.

Read Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)